Abstract

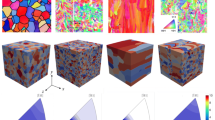

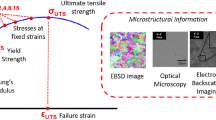

Additively manufactured metals can show more than an order of magnitude increase in variability in mechanical properties compared to traditionally manufactured materials. This makes the qualification of additively manufactured parts difficult, especially in safety critical applications where unexpected material failure can be detrimental. Sandia has been leading multiple efforts to understand the nature of this stochastic behavior by developing methodologies to efficiently characterize the variability in nominally identical parts, and investigating the role that stochastic defects, primarily voids, play in the deformation and fracture of components. In this talk we discuss the development of an automated high-throughput tensile testing set-up, utilized in a preliminary processing parameter study. We next discuss several studies that were motivated by this work where we utilized in situ micro-computed tomography to characterize the evolution of part geometry and void morphology in both simple and complex geometries, identifying the deformation mechanisms associated with void networks. Overall, these works have led to improvements in understanding the nature of stochasticity in additively manufactured metals and advancing our capabilities to predict and model failure in these materials.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bourell, D.L., Marcus, H.L., Barlow, J.W., Beaman, J.J., Deckard, C.R., University of Texas System.: Multiple material systems for selective beam sintering. U.S. Patent 4,944,817 (1990)

Lewandowski, J.J., Seifi, M.: Metal additive manufacturing: a review of mechanical properties. Annu. Rev. Mater. Res. 46, 151–186 (2016)

Foster, S.J., Carver, K., Dinwiddie, R.B., List, F., Unocic, K.A., Chaudhary, A., Babu, S.S.: Process-defect-structure-property correlations during laser powder bed fusion of alloy 718: role of in situ and ex situ characterizations. Metall. Mater. Trans. A. 49(11), 5775–5798 (2018)

Madison, J.D., Underwood, O.D., Swiler, L.P., Boyce, B.L., Jared, B.H., Rodelas, J.M., Salzbrenner, B.C.: Corroborating tomographic defect metrics with mechanical response in an additively manufactured precipitation-hardened stainless steel. AIP Conference Proceedings. 1949, 020009 (2018)

Boyce, B.L., Salzbrenner, B.C., Rodelas, J.M., Swiler, L.P., Madison, J.D., Jared, B.H., Shen, Y.: Extreme-value statistics reveal rare failure-critical defects in additive manufacturing. Adv. Eng. Mater. 19(8), 1700102 (2017)

Salzbrenner, B.C., Rodelas, J.M., Madison, J.D., Jared, B.H., Swiler, L.P., Shen, Y.L., Boyce, B.L.: High-throughput stochastic tensile performance of additively manufactured stainless steel. J. Mater. Process. Technol. 241, 1–12 (2017)

Gorsse, S., Hutchinson, C., Gouné, M., Banerjee, R.: Additive manufacturing of metals: a brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci. Technol. Adv. Mater. 18(1), 584–610 (2017)

Jared, B.H., Aguilo, M.A., Beghini, L.L., Boyce, B.L., Clark, B.W., Cook, A., Kaehr, B.J., Robbins, J.: Additive manufacturing: toward holistic design. Scr. Mater. 135, 141–147 (2017)

Standard Terminology for Additive Manufacturing – General Principles – Terminology, ISO/ASTM 52900:2015(e), ASTM International, (2016)

Heckman, N.M., Ivanoff, T.A., Roach, A.M., Jared, B.H., Tung, D.J., Brown-Shaklee, H.J., Huber, T., Saiz, D.J., Koepke, J.R., Rodelas, J.M., Madison, J.D., Salzbrenner, B.C., Swiler, L.P., Jones, R.E., Boyce, B.L.: Automated high-throughput tensile testing reveals stochastic process parameter sensitivity. Mater. Sci. Eng. A. 772, 138632 (2020)

Kramer, S.L.B., et al.: The third Sandia fracture challenge: predictions of ductile fracture in additively manufactured metal. Int. J. Fract. 218(1–2), 5–61 (2019)

Kramer, S.L.B., Ivanoff, T.A., Madison, J.D., Lentfer, A.P.: Evolution of damage and failure in an additively manufactured 316L SS structure: experimental reinvestigation of the third Sandia fracture challenge. Int. J. Fract. 218(1–2), 63–84 (2019)

Acknowledgements

Sandia National Laboratories is a multimission laboratory managed and operated by National Technology & Engineering Solutions of Sandia, LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-NA0003525.

This paper describes objective technical results and analysis. Any subjective views or opinions that might be expressed in the paper do not necessarily represent the views of the U.S. Department of Energy or the United States Government. SAND2020-2168 A.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Society for Experimental Mechanics, Inc.

About this paper

Cite this paper

Ivanoff, T.A., Heckman, N.M., Kramer, S.L.B., Madison, J.D., Jared, B.H., Boyce, B.L. (2021). Analytical Methods to Understand Deformation Mechanics in Additively Manufactured Metals. In: Kramer, S.L., Tighe, R. (eds) Thermomechanics & Infrared Imaging, Inverse Problem Methodologies and Mechanics of Additive & Advanced Manufactured Materials, Volume 7. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, Cham. https://doi.org/10.1007/978-3-030-59864-8_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-59864-8_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-59863-1

Online ISBN: 978-3-030-59864-8

eBook Packages: EngineeringEngineering (R0)