Abstract

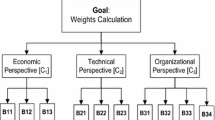

Manufacturing organizations are under constant pressure from regulatory bodies to reduce the environmental impact of their products and processes. The stiff competition is also among manufacturing organizations to improve their social image. Manufacturing organizations, especially in developing countries, are lagging behind their counterparts in developed countries in terms of commitment toward the environment. Green innovations at their organizations are the economic and viable solution to overcome this challenge. However, the manufacturing organizations are struggling to green their operations due to numerous barriers like lack of resources and unavailability of financial and human capital. It is often the internal barriers on which organizations have some control. This study identifies internal barriers to green innovation through literature review. A hybrid of three different methodologies is employed. First, ISM is employed to identify the relationship between these barriers. ISM also helps in identifying driving barriers that have the most effect on the system. Next, using BWM, the driving barriers are ranked. In the third step, VIKOR methodology is applied to rank the ability of manufacturing organizations in overcoming these barriers.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ahmadi, H. B., Kusi-Sarpong, S., & Rezaei, J. (2017). Assessing the social sustainability of supply chains using Best Worst Method. Resources, Conservation and Recycling, 126, 99–106.

Al-Muftah, H., Weerakkody, V., Rana, N. P., Sivarajah, U., & Irani, Z. (2018). Factors influencing e-diplomacy implementation: Exploring causal relationships using interpretive structural modelling. Government Information Quarterly, 35(3), 502–514.

Cecere, G., Corrocher, N., & Mancusi, M. L. (2018). Financial constraints and public funding of eco-innovation: Empirical evidence from European SMEs. Small Business Economics, 54, 285–302.

Chang, C. H. (2011). The influence of corporate environmental ethics on competitive advantage: the mediation role of green innovation. Journal of Business Ethics, 104(3), 361–370.

Chen, Y. S., Lai, S. B., & Wen, C. T. (2006). The influence of green innovation performance on corporate advantage in Taiwan. Journal of Business Ethics, 67(4), 331–339.

Collins, E., Lawrence, S., Pavlovich, K., & Ryan, C. (2007). Business networks and the uptake of sustainability practices: the case of New Zealand. Journal of Cleaner Production, 15(8-9), 729–740.

De Jesus, A., & Mendonça, S. (2018). Lost in transition? Drivers and barriers in the eco-innovation road to the circular economy. Ecological Economics, 145, 75–89.

Del Río, P., Carrillo-Hermosilla, J., & Könnölä, T. (2010). Policy strategies to promote eco-innovation: An integrated framework. Journal of Industrial Ecology, 14(4), 541–557.

Dubey, R., Gunasekaran, A., & Ali, S. S. (2015). Exploring the relationship between leadership, operational practices, institutional pressures and environmental performance: A framework for green supply chain. International Journal of Production Economics, 160, 120–132.

Dubey, R., Gunasekaran, A., Childe, S. J., Papadopoulos, T., Hazen, B., Giannakis, M., & Roubaud, D. (2017). Examining the effect of external pressures and organizational culture on shaping performance measurement systems (PMS) for sustainability benchmarking: Some empirical findings. International Journal of Production Economics, 193, 63–76.

Eiadat, Y., Kelly, A., Roche, F., & Eyadat, H. (2008). Green and competitive? An empirical test of the mediating role of environmental innovation strategy. Journal of World Business, 43(2), 131–145.

Fernando, Y., Jabbour, C. J. C., & Wah, W. X. (2019). Pursuing green growth in technology firms through the connections between environmental innovation and sustainable business performance: does service capability matter? Resources, Conservation and Recycling, 141, 8–20.

Govindan, K., Kaliyan, M., Kannan, D., & Haq, A. N. (2014). Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. International Journal of Production Economics, 147, 555–568.

Gupta, H. (2018). Evaluating service quality of airline industry using hybrid best worst method and VIKOR. Journal of Air Transport Management, 68, 35–47.

Gupta, H., & Barua, M. K. (2016). Identifying enablers of technological innovation for Indian MSMEs using best–worst multi criteria decision making method. Technological Forecasting and Social Change, 107, 69–79.

Gupta, H., & Barua, M. K. (2017). Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. Journal of Cleaner Production, 152, 242–258.

Gupta, H., & Barua, M. K. (2018). A framework to overcome barriers to green innovation in SMEs using BWM and Fuzzy TOPSIS. Science of the Total Environment, 633, 122–139.

Hafezalkotob, A., Hafezalkotob, A., Liao, H., & Herrera, F. (2019). An overview of MULTIMOORA for multi-criteria decision-making: Theory, developments, applications, and challenges. Information Fusion, 51, 145–177.

Hall, J., Matos, S., Silvestre, B., & Martin, M. (2011). Managing technological and social uncertainties of innovation: The evolution of Brazilian energy and agriculture. Technological Forecasting and Social Change, 78(7), 1147–1157.

Hermann, R. R., Mosgaard, M. A., & Kerndrup, S. (2016). The function of intermediaries in collaborative innovation processes: Retrofitting a Danish small island ferry with green technology. International Journal of Innovation and Sustainable Development, 10, 361.

Hughes, D. L., Rana, N. P., & Dwivedi, Y. K. (2019). Elucidation of IS project success factors: An interpretive structural modelling approach. Annals of Operations Research, 285, 35–66.

Kerr, W. R., & Nanda, R. (2015). Financing innovation. Annual Review of Financial Economics, 7, 445–462.

Liao, W., & Wang, T. (2018). Promoting green and sustainability: A multi-objective optimization method for the job-shop scheduling problem. Sustainability, 10(11), 4205.

Lin, C. Y., & Ho, Y. H. (2008). An empirical study on logistics service providers’ intention to adopt green innovations. Journal of Technology Management & Innovation, 3(1), 17–26.

Madrid-Guijarro, A., Garcia, D., & Van Auken, H. (2009). Barriers to innovation among Spanish manufacturing SMEs. Journal of Small Business Management, 47(4), 465–488.

Malek, J., & Desai, T. N. (2019). Interpretive structural modelling based analysis of sustainable manufacturing enablers. Journal of Cleaner Production, 238, 117996.

Mangla, S. K., Govindan, K., & Luthra, S. (2017). Prioritizing the barriers to achieve sustainable consumption and production trends in supply chains using fuzzy Analytical Hierarchy Process. Journal of cleaner production, 151, 509–525.

Opricovic, S. (1998). Multicriteria optimization of civil engineering systems. Faculty of Civil Engineering, Belgrade, 2(1), 5–21.

Pawanchik, A., & Sulaiman, S. (2010). In search of InnovAsian: the Malaysian innovation climate report 2010. Alpha Catalyst Consulting.

Perron, G. M. (2005). Barriers to environmental performance improvements in Canadian SMEs. Canada: Dalhousie University.

Porter, M. E., & Van der Linde, C. (1995). Green and competitive: ending the stalemate. Harvard Business Review, 73(5), 120–134.

Rezaei, J. (2015). Best-worst multi-criteria decision-making method. Omega, 53, 49–57.

Rezaei, J. (2016). Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega, 64, 126–130.

Rezaei, J., Nispeling, T., Sarkis, J., & Tavasszy, L. (2016). A supplier selection life cycle approach integrating traditional and environmental criteria using the best worst method. Journal of Cleaner Production, 135, 577–588.

Saunila, M., Ukko, J., & Rantala, T. (2018). Sustainability as a driver of green innovation investment and exploitation. Journal of cleaner production, 179, 631–641.

Song, M., & Wang, S. (2018). Market competition, green technology progress and comparative advantages in China. Management Decision, 56(1), 188–203.

Song, M., Peng, J., Wang, J., & Dong, L. (2018). Better resource management: An improved resource and environmental efficiency evaluation approach that considers undesirable outputs. Resources, Conservation and Recycling, 128, 197–205.

Tam, V. W., Tam, C. M., Shen, L. Y., Zeng, S. X., & Ho, C. M. (2006). Environmental performance assessment: perceptions of project managers on the relationship between operational and environmental performance indicators. Construction Management and Economics, 24(3), 287–299.

Walker, H., Di Sisto, L., & McBain, D. (2008). Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. Journal of purchasing and supply management, 14(1), 69–85.

Warfield, J. N. (1974). Developing interconnection matrices in structural modeling. IEEE Transactions on Systems, Man, and Cybernetics, (1), 81–87.

Xia, D., Zhang, M., Yu, Q., & Tu, Y. (2019). Developing a framework to identify barriers of Green technology adoption for enterprises. Resources, Conservation and Recycling, 143, 99–110.

Zhao, H., Guo, S., & Zhao, H. (2018). Comprehensive benefit evaluation of eco-industrial parks by employing the best-worst method based on circular economy and sustainability. Environment, Development and Sustainability, 20(3), 1229–1253.

Zhe, L., Yong, G., Hung-Suck, P., Huijuan, D., Liang, D., & Tsuyoshi, F. (2016). An emergy-based hybrid method for assessing industrial symbiosis of an industrial park. Journal of Cleaner Production, 114, 132–140.

Zhu, Q., & Sarkis, J. (2007). The moderating effects of institutional pressures on emergent green supply chain practices and performance. International Journal of Production Research, 45(18-19), 4333–4355.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Gupta, H., Barua, M.K. (2021). Evaluation of Manufacturing Organizations Ability to Overcome Internal Barriers to Green Innovations. In: Rezaei, J. (eds) Strategic Decision Making for Sustainable Management of Industrial Networks. Greening of Industry Networks Studies, vol 8. Springer, Cham. https://doi.org/10.1007/978-3-030-55385-2_8

Download citation

DOI: https://doi.org/10.1007/978-3-030-55385-2_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-55384-5

Online ISBN: 978-3-030-55385-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)