Abstract

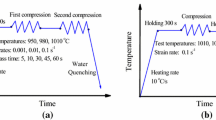

M647, a Ni-based superalloy with excellent mechanical properties and good hot deformability, was recently developed for application in airplane engine disks. In airplane engines, fine-grained superalloys are required to improve high-temperature fatigue properties. Methods to control fine grains have been extensively studied, including a refined method of applying the pinning effect of a coarse γ′ phase. However, previous reports focused on the mechanism of nucleation and abnormal grain growth, and reports on modeling to predict grain size are rare, making it difficult to optimize the forging process. The present study proposes a modeling method of M647 recrystallization with a coarse γ’ phase and compares modeling and experimental results. Recrystallization was experimentally observed in M647 with a coarse γ′ phase originating from the grain boundaries of the prior γ phase. Moreover, recrystallization is promoted by heating at a high temperature, applying a high strain, and maintaining the heat for a long duration. Grain growth is restricted by the pinning effect of the coarse γ′ phase. The area fraction of the coarse γ′ phase changed with the heating temperature, and the γ′ grain size increased with heating. Electron backscatter diffraction analysis shows that the kernel average misorientation increased with increasing forging temperature. These trends indicate that the pinning and driving forces of recrystallization fluctuate continuously during forging and reheating. The microstructure is predicted by applying Avrami-type equations, but the accuracy is insufficient because the fluctuation effects are not considered.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Barker JF (1989) The initial years of Alloy 718 – A GE perspective. In: Loria, EA (ed) Superalloys 718–Metallurgy and Applications. The Minerals, Metals & Materials Society, p 269–278.

Schafrik RE, Ward, DD, Groh, JR (2001) Application of Alloy 718 in GE aircraft engines: Past, present, and next five years. In: Loria, EA (ed) Superalloys 718, 625, 706 & Various Derivatives. The Minerals, Metals & Materials Society, p 1–11.

Paulonis DF, Schirra JJ (2001) Alloy 718 at Pratt & Whitney–Historical perspective and future challenges. In: Loria, EA (ed) Superalloys 718, 625, 706 & Various Derivatives. The Minerals, Metals & Materials Society, p 13–23.

Xie Z, Wang G, Dong J, Xu C, Cao W, Kennedy R (2005) Structure stability study on a newly developed Nickel-base superalloy – ALLVAC 718PLUS. In: Loria, EA (ed) Superalloys 718, 625, 706 & Various Derivatives. The Minerals, Metals & Materials Society, p 179–191.

Heaney JA, Lasonde ML, Powell AM, Bond BJ, O’Brien CM (2014) Development of a new cast and wrought alloy (RENE65) for high temperature disk applications. Paper presented at the 8th International Symposium on Superalloy 718 and Derivatives, The Minerals, Metals & Materials Society, p 67–77, 2014.

Devaux A, Picque B, Gervais MF, Georges E, Poulain T, Heritire P (2012) AD730TM–A new nickel-based superalloy for high temperature engine rotative parts. Superalloys 2012, The Minerals, Metals & Materials Society, p 911–919.

Miao J, Pollock TM, Jones JW (2012) Microstructural extremes and the transition from fatigue crack initiation to small crack growth in a polycrystalline nickel-base superalloy. Acta Mater. 60:2840–2854.

Brogdon ML, Rosenberger AH (2008) Evaluation of the influence of grain structure on the fatigue variability of Waspaloy. Paper presented at the 11th International Symposium on Superalloys, Champion, Pennsylvania, 14–18 September 2008.

Ruan JJ, Ueshima N, Oikawa K (2018) Phase transformations and grain growth behaviors in Superalloy 718. J. Alloys Compd. 737:83–91.

Yoshida H (2006) Paper presented at the International Forgemasters Meeting, Sheffield, United Kingdom, 15–19 October 2006.

Charpagne MA, Billot T, Franchet JM, Bozzolo N (2016) Heteroepitaxial recrystallization observed in RENE65tm and UDIMET 720tm; a new recrystallization mechanism possibly occurring in all low lattice mismatch γ-γ′ superalloys. Paper presented at the 13th International Symposium on Superalloys, Seven Springs, Pennsylvania, 11–15 September 2016.

Bi Z, Lv X, Zhang J (2014) Solutions for the “difficult-to-deform” wrought superalloys. Paper presented at the 2nd International Symposium on EUROSUPERALLOYS 2014, 2014.

Charpagne MA, Franchet JM, Bozzolo N (2018) Overgrown grains appearing during sub-solvus heat treatment in a polycrystalline γ-γ′ nickel-based superalloy. Mater. Des 144:353–360.

Perez M, Dumont C, Nodin O, Nouveau S (2018) Impact of forging direction on the recrystallization behavior of nickel base superalloy AD730 billet material at sub solvus temperature. Mater. Charact. 146:169–181.

Brooks JW (2000) Forging of superalloys. Mater. Des 21:297–303.

Shen G, Rollins J, Furrer D (1996) Microstructure modeling of forged Waspaloy discs. Paper presented at the 8th International Symposium on Superalloys, Champion, Pennsylvania, 22–26 September 1996.

Christiansen P, Martins PAF, Bay N (2016) Friction compression in the upsetting of cylindrical test specimens. Exp. Mech. 56:1271–1279.

Okajima T, Sakurai S, Fujiwara M (2014) Paper presented at the 19th International Forgemasters Meeting, Tokyo, Japan, 29 September–3 October 2014.

Umezaki S, Murata Y, Nomura K, Kubushiro K (2014) Quantitative analysis of dislocation density in an austenitic steel after plastic deformation. J. Jpn. Inst. Met. Meter. 78:218–224.

Sellars CM (1980) Hot working and forming processes. In: Sellars CM and Davies GJ (eds), The Metals Society, London, p 3.

Zurob HS, Hutchinson CR, Brechet Y, Purdy G (2002) Modeling recrystallization of microalloyed austenite: Effect of coupling recovery, precipitation and recrystallization. Acta Mater. 50:3075–3092.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Nishimoto, T., Okajima, T., Yamashita, K., Zhang, Q., Gong, J., Olson, G. (2020). Impact of Coarse γ′ Phase on Recrystallization Modeling in New Ni-Based Superalloy M647. In: Tin, S., et al. Superalloys 2020. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-51834-9_47

Download citation

DOI: https://doi.org/10.1007/978-3-030-51834-9_47

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-51833-2

Online ISBN: 978-3-030-51834-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)