Abstract

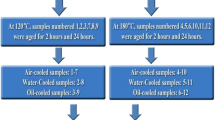

The present study is an attempt to study the effect of double-aging process and its relevant parameters (like time, temperature and quenching media) on the mechanical properties of two types of aluminum alloys. AA7075 and AA6061 are selected in this study to examine their responses to the double-aging. Fabricated specimens are heat treated, and tested for hardness using micro-Vickers hardness test. They are then artificially aged at 150 °C for different aging periods. The specimens are then quenched in water and oil. Hardness test are then repeated to determine the optimum time and cooling rate that give the maximum (peak) hardness values. This procedure are repeated on other sets of specimens, but with double aging at 185 °C to find out which alloy has more significant response to double ageing. The outcomes of the study show that the 7075 aluminum alloy demonstrates better results than those obtained for the 6061 aluminum alloys. Increase in hardness from 135.66 HV to 150.61 HV is reported for the 7075 aluminum alloy.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

ASM: Metals Handbook Desk Edition, 2nd edn., vol. 1 (1998)

Hatch, J.E.: Aluminum Properties and Physical Metallurgy. ASM International, Metals Park (1984)

GSA, Aluminum: Characteristics, Uses and Problems (2016). http://www.gsa.gov

Polmear, I.J.: Recent developments in light alloys. Mater. Trans. JIM 37(1), 12–31 (1996)

Staley, J.T.: History of Wrought-Aluminium-Alloy Development. Aluminium Alloys: Contemporary Research and Applications, Treaties on Materials Science and Technology, Academic Press, 31 (1989). Table 1: chemical composition for 6061 and 7075 aluminum alloys

Abúndez, A., Pereyrab, I., Campillo, B.: Improvement of ultimate tensile strength by artificial ageing and retrogression treatment of aluminium alloy 6061. Mater. Sci. Eng. A 668, 201–207 (2016)

Rajaa, S.M., Abdulhadi, H.A., Jabur, K.S., Mohammed, G.R.: Aging time effects on the mechanical properties of Al 6061-T6 alloy. Eng. Technol. Appl. Sci. Res. 8(4), 3113–3115 (2018)

Zhao, Q.-L., Shan, T.-T., Geng, R., Zhang, Y.-Y., He, H.-Y., Qiu, F., Jiang, Q.-C.: Effect of preheating temperature on the microstructure and tensile properties of 6061 aluminum alloy processed by hot rolling-quenching. Metals 9, 182 (2019). https://doi.org/10.3390/met9020182

Masoud, I.M., Abu Mansour, T., Al-Jarrah, J.A.: Effect of heat treatment on the microstructure and hardening properties of 6061 aluminum alloy. J. Appl. Sci. Res. 8(10), 5106–5113 (2012). ISSN 1819-544X

Tan, C.F., Said, M.R.: Effect of hardness test on precipitation hardening aluminium alloy 6061-T6. Chiang Mai J. Sci. 36(3), 276–286 (2009). www.science.cmu.ac.th/journal-science/josci.html

Cina, B.M., Gan, R.: Reducing the susceptibility of alloys particularly aluminum alloys to stress corrosion cracking. Israel Aircraft Industries Ltd., U.S. Patent 3856584, 1974-12-24

Shenoy, H.G., Chetty, S.V., Premkumar, S.: Evaluation of wear and hardness of al-si-mg based hybrid composite at different aging conditions (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Al-Lubani, S.E., Ateyat, A.I. (2020). Double Aging of Heat-Treated Aluminum Alloy of (7075) and (6061) to Increase the Hardness Number. In: Indeitsev, D., Krivtsov, A. (eds) Advanced Problems in Mechanics. APM 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-49882-5_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-49882-5_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-49881-8

Online ISBN: 978-3-030-49882-5

eBook Packages: EngineeringEngineering (R0)