Abstract

The development of industrial clusters has, until recently, been guided solely by economic considerations. Recent advances in measuring and assessing the environmental and social consequences of industrial production have revealed the impact of human activity on the environment and society. Eco-Industrial Networks (EINs) are being viewed as a possible solution for reducing the environmental consequences of industrial production. In this paper, we review existing approaches used for analyzing and designing EINs. Based on salient works, design requirements for models to facilitate the organization of EINs are presented and discussed.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

14.1 Introduction

Increased attention is being paid to ecosystems and the consumption of resources. As a result, governments and commercial organizations are supporting shifts towards sustainable development. There are many examples of this: companies are being held liable for their environmental impact in many regions all over the world (Abdullah et al. 2019; Roberts 2004) and some countries, for instance China, have gone a step further by promoting a comprehensive legal strategy called circular economy (Yuan et al. 2006). When proposing the concept of industrial ecology, Frosch and Gallopoulos (1989) suggested a holistic approach for companies to efficiently achieve improvements in all three dimensions of sustainable development, economy, environment, and society, suggesting that industrial systems should operate like natural eco-systems (Frosch 1994; Allenby 1992; Jelinski et al. 1992). The waste and byproducts of one company could be the inputs of another (Abdullah et al. 2019). This can be done by setting up Eco-Industrial Parks (EIPs) or Networks (EINs), which involve the cooperation of companies and communities sharing and using their resources and byproducts, synergistically reducing waste. Economies of scale can help to achieve economic improvements (Tudor et al. 2007). The case of Kalundborg in Denmark is one of many promising examples (Ehrenfeld 1997; Bain et al. 2010). However, Drexhage and Murphy (2012) and Gu et al. (2013) claim that this concept exists mainly in theory and that successful cases are not set up from scratch, however have developed in response to fortunate circumstances. Although there is governmental and private interest for designing and operating industrial parks or networks, the literature does not reveal much in the way of mathematical and computational modeling for the improvement and design of corporative networks. The development of such models can help to support the process of turning the key concepts of the idea of industrial ecology by providing optimal decisions, assessing patterns, and investigating key factors in the design and operation of EINs (Gu et al. 2013). This paper aims to map the mathematical approaches used for EIN design and indicate how they may be used for designs in the future.

14.2 Literature Review and Modeling Requirements

Eco-Industrial Networks and related concepts have been identified by many different authors over the last two decades (Gu et al. 2013; Veiga and Magrini 2009; Lowe 2001; Schlarb 2001; Chertow 2000; Côté and Cohen-Rosenthal 1998; Côté and Hall 1995). The principal related definitions are:

Eco-industrial park (EIP): “An eco-industrial park or estate is a community of manufacturing and service businesses located together on a common property” (Lowe 2001). Eco-industrial Networks: EIPs without geographic proximity (Ehrenfeld and Chertow 2002). The terms “industrial symbiosis networks” (Domenech and Davies 2011), and “zero waste networks” (Curran and Williams 2012) are interchangeable. The participants of a geographically spread virtual EIP are EINs. Roberts defined EINs as “networks of EIPs at national or global levels” (Roberts 2004).

An appraisal of the literature on the application of modeling methods and optimization approaches used in the field of Industrial Ecology as related to EINs has been conducted. The search was conducted with Google Scholar primarily, using terms such as: “EIN”, eco industrial parks”, “circular economy” with “mathematical model”, “optimization” etc. From the resultant list, salient articles were identified based on the type of solution methodology used, and these have been reported in this paper. These approaches are clustered (Table 14.1) based on the method used and classified according the discussion in the previous paragraphs. Some proposed models may be part of more than one cluster. The cluster bi-level fuzzy optimization requires, for example, a fuzzy optimization, and mixed-integer linear programming (MILP) or mixed-integer non-linear programming (MINLP), which are clusters themselves. The clusters represent main practices of approaching modeling of industrial ecology.

Walther et al. (2008), and Miettinen (1999) develop a negotiation algorithm for the coordination of material flow in recycling networks. The idea of industrial ecology has not been mentioned in these publications; however, based on mathematical models and an interactive negotiation algorithm, new symbiosis can be created. In order to solve the optimization model, Lagrange relaxation is applied. While the original objective function contains economic measurements, the Lagrange relaxation allows a variation of the recycling rate and thus accounts for environmental issues. Penalty functions are a common multi-objective optimization method (Miettinen 1999). Pishvaee et al. (2009) provide a meta-investigation of modeling approaches for reverse and integrated networks considering uncertainty.

While the subject matter of this investigation is a sustainable reverse logistics network, environmental targets or the idea of industrial ecology have not been applied. Different methodologies have been developed in the literature in order to solve multi-objective optimization models (Walther et al. 2008). A successful application of the NIMBUS (non-differentiable interactive multi-objective bundle-based optimization system) method to optimization of eco-industrial parks has been proposed by Gu et. al. (2013); they apply the whole process of an interactive multi-objective optimization to both eco-industrial park design and optimization; this composition of computational and mathematical modeling considers multiple waste product flows. Since this tool is web-based, it is considered to have a high usability. Erol and Thöming (2005) consider multiple stakeholders with an interactive negotiation framework, neglecting social performance; uncertain behavior is also not considered. This methodology supports the improvement and design of eco-industrial parks. Li et al. (2009) consider chemical processes in general for industrial ecology; they apply TOPSIS (technique for order preference by similarity to ideal solution) and solve with an NSGA-II (non-dominated sorting generic algorithm). Erol and Thöming (2005) combine the simultaneous analysis of environmental impact sensitivity (SAEIS) with multi-objective optimization performed by MINLP; they model the trade-off between economy and environment under consideration of life cycle analysis (LCA) factors. Li et al. (2009) provide the basis for this approach by illustrating the application of LCA to process optimization. The interactive surrogate worth trade-off method (ISWT) has only been applied to power plants, not to EIPs.

Taskhiri et al. (2011) suggest a model to achieve a compromise among the potentially conflicting fuzzy goals of the various EIP stakeholders. Unlike the following approach, this mathematical optimization model does not consider a hierarchical structure. Karlsson and Wolf (2007) consider the hierarchy of decision-making in an eco-industrial park using a bi-level fuzzy optimization; they take into account the participating plants by means of an individual fuzzy cost goal while the upper level and overall goal of an EIP authority is the minimization of resource consumption and generation of waste. Their model thus includes environmental and economic targets but does not consider social issues.

Using a fuzzy function, lower and upper boundaries are included and provide a range in which alternative economic outcomes are acceptable for participants. The bi-level especially considers the hierarchy of stakeholders. It applies the Stackelberg Game to mathematical optimization. The basic idea of applying game theory approaches has also been investigated by Chew et al. (2009). This multi-objective bi-level optimization has also been applied to other problems such as transport planning and management problems in the past, and Kastner et al. (2015), and Yin (2002) use a nonlinear solver to find an optimal solution of an example case. The application of the max-min-concept seeks to maximize the satisfaction of the least satisfied company.

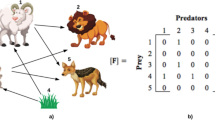

Huo and Chai (2008) set up a simulation to understand evolution of industrial ecology patterns and provide new implications for design, improvement, and prediction of structural evolutions. They investigate patterns and apply evolutionary principles as well as nonlinear partial differential equations with boundary conditions and thus computationally implement interacting organisms. Evolutionary algorithms solve many nonlinear programs, and are can be used to solve multi-objective optimization problems (Zitzler and Thiele 1999). However, other than Qu et al. (2014), most of the nonlinear programs have an underlying mathematical model to be solved.

Romero and Ruiz (2013, 2014) propose the application of agent-based modeling to the optimization and design of eco-industrial parks. Single companies are implemented as agents with an individual behavior and an individual economic and ecological goal (Bichraoui et al. 2013). Among other notable approaches, LCA is product based and not based on company level approach for handling eco-industrial models. However, Tong et al. (2013) applies the LCA to a system for water reuse in an industrial park. In order to determine the correct partners for increasing competitive advantage, many mathematical programming models, such as linear programming (Pan 1998), stochastic integer programming (Afshari et al. 2016), and multi-objective programming (Huang et al. 2010) have been proposed.

14.3 Analysis and Requirements

Based on the literature review, eight requirements for modeling EINs can be identified. Models should be able to include (i) Economic objectives; (ii) Environmental objectives; (iii) Social objectives; (iv) Multiple flows; (v) Multiple stakeholders; (vi) Negotiation of alternatives; (vii) Uncertainty; (viii) Ability to generate optimal solutions; and (ix) Usability. The relative importance of the requirements is dependent on the particular situation, but a comprehensive model for an EIN should address all these requirements.

The development potential of the different approaches is shown in Table 14.2 by four categories: A, B, C and D. Category A: for analysis usefulness; B: for improvements; C: for extending capabilities; and D: for design of Eco-Industrial Networks. From the table, if the goal of the model being developed relates to metrics associated with multiple flows, Input-Output analysis, Material Flow and Lagrangian Penalty based methods can be used for the purpose. Similarly, based on the development potential, Input-Output analysis, Material Flow can be used for analyzing exchanges in Eco-Industrial Networks. Likewise, Mixed Integer Programming, Agent based approaches can be used for designing new EINs. Multicriteria methods, Fuzzy approaches and Bilevel programming have been used for improving existing networks, and, Evolutionary and System Dynamics methods can be used to extend/augment existing EINs either by extending the network size or by including additional materials.

14.4 Summary

Some special patterns have been discovered in this review of mathematical approaches for modeling and designing EINs. There is no current method for achieving an optimized decision for creating new eco-industrial parks and networks. The only approach providing such an idea has been proposed by Romero and Ruiz (2013, 2014). While nearly every modeling approach that has been applied by a publication in the field of industrial ecology directly considers economic and ecological performance indicators in the objective functions, social performance has not been addressed. It is noteworthy that most of the publications only consider a single flow of material in a network; useful by-products are rarely considered explicitly by any model.

Based on the review, several design requirements for modeling EINs are determined. The domain requirements and the modeling techniques best suited for each domain are mapped. Future work on the use of these requirements for designing EINs for developing economies is ongoing.

References

Abdullah R, Malik E, Pratiwi ET, Abdullah L, Sulili A., Heliawaty (2019) Influence of corporate social responsibility on company performance. IOP Conf Ser: Earth Environ Sci 235(1):012004

Afshari H, Farel R, Peng Q (2016) Need for optimization under uncertainty: designing flow exchanges in Eco-Industrial Parks. In: ASME 2016 international design engineering technical conferences and computers and information in engineering conference, V004T05A046–V004T05A046, American Society of Mechanical Engineers

Allenby BR (1992) Achieving sustainable development through industrial ecology. Int Environ Aff 4(1):56–68

Ayres RU, Ayres LW (eds) (2002) A handbook of industrial ecology. Edward Elgar Publishing, Northampton

Azapagic A, Clift R (1999) The application of life cycle assessment to process optimisation. Comput Chem Eng 23(10):1509–1526

Bain A, Shenoy M, Ashton W, Chertow M (2010) Industrial symbiosis and waste recovery in an Indian industrial area. Resour Conser Recycl 54(12):1278–1287

Bichraoui N, Guillaume B, Halog A (2013) Agent-based modelling simulation for the development of an industrial symbiosis-preliminary results. Procedia Environ Sci 17:195–204

Boix M, Montastruc L, Azzaro-Pantel C, Domenech S (2015) Optimization methods applied to the design of eco-industrial parks: a literature review. J Clean Prod 87:303–317

Bringezu S, Moriguchi Y (2002) Material flow analysis. In: A handbook of industrial ecology, pp 79–110

Bringezu S, Moriguchi Y (2018) Material flow analysis. In: Bartelmus P, Seifert EK (eds) Green accounting. Routeledge (2018).

Bringezu S, Fischer-Kowalski M, Kleijn R, Palm V (1997) Regional and national material flow accounting: From paradigm to practice of sustainability. In: Proceedings of the ConAccount workshop. Leiden, The Netherlands, 21–23 Jan 1997

Chertow MR (2000) Industrial symbiosis: literature and taxonomy. Ann Rev Energy Environ 25(1):313–337

Chew IML, Tan RR, Foo DCY, Chiu ASF (2009) Game theory approach to the analysis of inter-plant water integration in an eco-industrial park. J Clean Prod 17(18):1611–1619

Côté RP, Cohen-Rosenthal E (1998) Designing eco-industrial parks: a synthesis of some experiences. J Clean Prod 6(3):181–188

Côté R, Hall J (1995) Industrial parks as ecosystems. J Clean Prod 3(1):41–46

Curran T, Williams IDA (2012) Zero waste vision for industrial networks in Europe. J Hazard Mater 207:3–7

Domenech T, Davies M (2011) Structure and morphology of industrial symbiosis networks: the case of Kalundborg. Procedia-Soc Behav Sci 10:79–89

Drexhage J, Murphy D (2012) Sustainable development: from Brundtland to Rio 2012. In: Background paper for the high level panel on global sustainability. United Nations, New York

Duchin F (1992) Industrial input-output analysis: implications for industrial ecology. Proc Natl Acad Sci 89(3):851–855

Ehrenfeld JR (1997) Industrial ecology: a framework for product and process design. J Clean Prod 5(1):87–95

Ehrenfeld JR, Chertow MR (2002) Industrial symbiosis: the legacy of Kalundborg. In: Ayres RU, Ayres LW (eds) A handbook of industrial ecology. Edward Elgar

Erol P, Thöming J (2005) ECO-design of reuse and recycling networks by multi-objective optimization. J Clean Prod 13(15):1492–1503

Frosch RA (1994) Industrial ecology: minimizing the impact of industrial waste. Phys Today 47(11):63–68

Frosch RA, Gallopoulos NE (1989) Strategies for manufacturing. Sci Am 261(3):144–152

Geng Y, Fujita T, Park HS, Chiu ASF, Huisingh D (2016) Recent progress on innovative eco-industrial development. J Clean Prod 114:1–10

Gonela V, Zhang J (2014) Design of the optimal industrial symbiosis system to improve bioethanol production. J Clean Prod 64:513–534

Gu C, Estel L, Yassine A, Leveneur S (2013) Multi-objective optimization for industrial ecology: design and optimize exchange flows in an industrial park. In: Proceedings of the 2013 international conference on applied mathematics and computational methods (AMCM 2013), pp 109–116

Huang JJ, Chen CY, Liu HH, Tzeng GH (2010) A multi-objective programming model for partner selection-perspectives of objective synergies and resource allocations. Expert Syst Appl 37(5):3530–3536

Huo CH, Chai LH (2008) Physical principles and simulations on the structural evolution of Eco-Industrial systems. J Clean Prod 16(18):1995–2005

Jelinski LW, Graedel TE, Laudise RA, McCall DW, Patel CK (1992) Industrial ecology: concepts and approaches. Proc Natl Acad Sci 89(3):793–797

Karlsson M, Wolf A (2007) Using an optimization model to evaluate the economic benefits of industrial symbiosis in the forest industry. J Clean Prod 16(14):1536–1544

Kastner CA, Lau R, Kraft M (2015) Quantitative tools for cultivating symbiosis in industrial parks: a literature review. Appl Energy 155:599–612

Kuznetsova E, Louhichi R, Zio E, Farel R (2017) Input-output Inoperability Model for the risk analysis of eco-industrial parks. J Clean Prod 164:779–792

Lee S, Yoo C, Choi SK, Chun HD, Lee I-B (2006) Modeling of Eco-industrial Park (EIP) through material flow analysis (MFA). Korean Chem Eng Res 44:579–587

Li C, Zhang X, Zhang S, Suzuki K (2009) Environmentally conscious design of chemical processes and products: multi-optimization method. Chem Eng Res Des 87(2):233–243

Lowe EA (2001) Eco-industrial park handbook for Asian developing countries. Report to Asian Development Bank. Asian Development Bank. Oakland, CA

Mantese GC, Amaral DC (2017) Comparison of industrial symbiosis indicators through agent-based modeling. J Clean Prod 140:1652–1671

Miettinen K (1999) Nonlinear multiobjective optimization, vol 12. Springer

Pan AC (1998) Allocation of order quantity among suppliers. J Purch Mater Manage 25(3):36

Pishvaee MS, Jolai F, Razmi J (2009) A stochastic optimization model for integrated forward/reverse logistics network design. J Manuf Syst 28(4):107–114

Qu Y, Bektaş T, Bennell J (2014) Sustainability SI: multimode multicommodity network design model for intermodal freight transportation with transfer and emission costs. Netw Spat Econ 1–27

Roberts BH (2004) The application of industrial ecology principles and planning guidelines for the development of eco-industrial parks: an Australian case study. J Clean Prod 12(8):997–1010

Romero E, Ruiz MC (2013) Framework for applying a complex adaptive system approach to model the operation of eco-industrial parks. J Ind Ecol 17(5):731–741

Romero E, Ruiz MC (2014) Proposal of an agent-based analytical model to convert industrial areas in industrial eco-systems. Sci Total Environ 468:394–405

Schlarb M (2001) Eco-industrial development: a strategy for building sustainable communities. Rev Econ Dev Inter Pract 8

Taskhiri MS, Tan RR, Chiu AS (2011) Emergy-based fuzzy optimization approach for water reuse in an eco-industrial park. Resour Conserv Recycl 55(7):730–737

Theo W, Lim LS, Wan Alwi SA, Mohammad Rozali NE, Ho WSH, Abdul-Manan Z (2016) An MILP model for cost-optimal planning of an on-grid hybrid power system for an eco-industrial park. Energy 116:1423–1441

Tong L, Liu X, Liu X, Yuan Z, Zhang Q (2013) Life cycle assessment of water reuse systems in an industrial park. J Environ Manage 129:471–478

Tudor T, Adam E, Bates M (2007) Drivers and limitations for the successful development and functioning of EIPs (eco-industrial parks): a literature review. Ecol Econ 61(2):199–207

Veiga LB, Magrini A (2009) Eco-industrial park development in Rio de Janeiro, Brazil: a tool for sustainable development. J Clean Prod 17(7):653–661

Walther G, Schmid E, Spengler TS (2008) Negotiation-based coordination in product recovery networks. Int J Prod Econ 111(2):334–350

Yin Y (2002) Multiobjective bilevel optimization for transportation planning and management problems. J Adv Transp 36(1):93–105

Yuan Z, Bi J, Moriguichi Y (2006) The circular economy: a new development strategy in China. J Ind Ecol 10(1–2):4–8

Zitzler E, Thiele L (1999) Multiobjective evolutionary algorithms: a comparative case study and the strength Pareto approach. IEEE Trans Evol Comput 3(4):257–271

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2020 The Author(s)

About this paper

Cite this paper

Sodhi, M., Schulze, F., Bissett, C., Rivero-Hudec, M. (2020). Modeling Eco-Industrial Networks—A Representative Literature Review and Design Requirements. In: Sangwan, K., Herrmann, C. (eds) Enhancing Future Skills and Entrepreneurship. Sustainable Production, Life Cycle Engineering and Management. Springer, Cham. https://doi.org/10.1007/978-3-030-44248-4_14

Download citation

DOI: https://doi.org/10.1007/978-3-030-44248-4_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-44247-7

Online ISBN: 978-3-030-44248-4

eBook Packages: EngineeringEngineering (R0)