Abstract

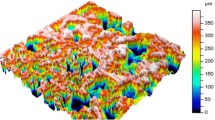

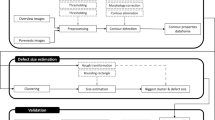

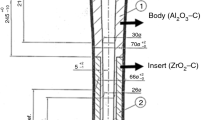

This study presents the results of an investigation that characterises the thermophysical properties of an investment casting mould, comprising of a Zirconium dioxide/Cobalt aluminate prime slurry and a fused Silica/fibre reinforced backup slurry. Growing prevalence of successful computer simulations within the foundry industry enables defects that emerge during the casting process to become increasingly predictable, providing cost-effective alternatives to trial castings. The viability of these simulations as predictors is heavily dependent upon the facilitation of accurate material property data, as attained through this investigation. Differential scanning calorimetry (DSC) and laser flash analysis (LFA) were utilized to determine the specific heat capacity and thermal diffusivity, respectively. These values, in combination with the material density and linear coefficient of thermal expansion, have been used to determine the thermal conductivity of the mould. With the aim of verifying these parameters, initial studies in Flow-3D® simulation software have been performed to determine the constraints needed to reduce variability in simulation parameters. Due to the diversity of casting moulds used throughout the industry, ensuring the material database is kept as comprehensively populated as possible is a crucial undertaking.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Jolly M (2003) Castings. In: Karihaloo B (ed) Comprehensive structural integrity. Elsevier, Oxford, pp 377–466

Kuljanic E (2005) (ed) Advanced manufacturing systems and technology. Springer, Wien, New York

Hendricks MJ, Wang PMJ, Filbrun RA, Well DK (1998) Hot MOR and creep properties of common ceramic shell refractories. In: 46th annual technical meeting of the investment casting institute

Wolfe CM, Holubik KL, Hendricks MJ, Wang PMJ (2010) How ceramic shell properties predict resistance to shell cracking, pp 1–16

Hendricks MJ (1990) An analysis of ceramic shell materials. In: 21st European conference on investment casting

Raza M (2018) Developing process design methodology for investment cast thin-walled structures. Malardalen University

Gebelin J, Jolly MR (2001) Modelling filters in investment casting. In: FOCAST 2nd mini conference

Chapman LA et al (2008) Properties of alloys and moulds relevant to investment casting

Jones S (2000) Summary of standard shell properties obtained for inclusion in modelling development. In: FOCAST 1st mini conference

Konrad CH, Brunner M, Kyrgyzbaev K, Völkl R, Glatzel U (2011) Determination of heat transfer coefficient and ceramic mold material parameters for alloy IN738LC investment castings. J Mater Process Technol 211(2):181–186

Gornostayev S, Kerkkonen O, Harkki JJ (2006) Importance of mineralogical data for influencing properties of coke. Process Metall 770–773

Matsushita T, Ghassemali E, Saro A, Elmquist L, Jarfors A (2015) On thermal expansion and density of CGI and SGI cast irons. Metals (Basel) 5(2):1000–1019

Xu M (2015) Characterization of investment shell thermal properties

Xu M, Lekakh SN, Von Richards L (2016) Thermal property database for investment casting shells. Int J Met 10(3):342–347

Pohanka M, Woodbury KA, Woolley J (2002) Obtaining temperature-dependent thermal properties of investment casting mold. In ASME international mechanical engineering congress and exposition

Acknowledgements

The authors wish to thank the Engineering and Physical Sciences Research Council (EPSRC) [Grant EP/L016389/1] and TPC Components AB for providing the necessary funding for this research.

The authors wish to thank Cranfield University, Jonkoping University, and the University of Warwick for providing access to scientific equipment needed to complete these investigations.

The authors wish to specifically thank Dr. Jacob Steggo and Jörgen Eriksson for their outstanding support during this research.

The data used in this paper is described in CORD at http://doi.org/10.17862/cranfield.rd.9934280.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Jones, C.A., Jolly, M.R., Jarfors, A.E.W., Irwin, M. (2020). An Experimental Characterization of Thermophysical Properties of a Porous Ceramic Shell Used in the Investment Casting Process. In: TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36296-6_102

Download citation

DOI: https://doi.org/10.1007/978-3-030-36296-6_102

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36295-9

Online ISBN: 978-3-030-36296-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)