Abstract

Microhardness of eolian gold – new morphologic type of placer gold, is studied. Flaky gold particles with a elevation at the periphery, as well as gold of toroidal and globular-hollow forms belong to eolian gold. Genesis of eolian gold is related to mechanical transformation of flaky gold particles into toroidal, and then into globular-hollow form in eolian conditions, that is experimentally proven. Previous studies determined changes of microhardness, mainly from 47 kg/mm2 to 100 kg/mm2, lower limit – 40 kg/mm2. But, low microhardness was identified in globular-hollow gold for the first time, which stood at 21 kg/mm2. This is due to the fact that, as a result of transformation of flaky gold in eolian conditions, under mechanical and chemical processes, silver and trace elements were removed, that led to fineness increase up to 1000‰, and to decompaction of inner structure of gold, that influenced microhardness indices. Identified patterns in nature, microhardness changes under mechanogenic and chemical process impact in eolian conditions, can be successfully used in gold metallurgy to produce gold alloys with very low microhardness.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Microhardness of gold was earlier studied by Lebedeva (1963), Badalova et al. (1968), Petrovskaya (1968), Popenko (1982). Previous researchers identified that, microhardness changes on the average from 40 to 100 kg/mm2 and depends on chemical composition of gold (percentage of silver and trace elements) and its inner structure. It is known that, Ag and Cu trace elements significantly increase hardness of gold alloys. Trace element presence (Pt, Sn, Al) also causes sharp increase of gold hardness. Gold of low fineness (550–650‰) has the biggest microhardness (Popenko 1982).

2 Methods and Approaches

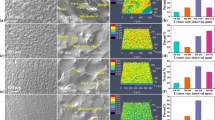

Microhardness of globular-hollow eolian gold was studied by microhardness tester PMT-3. In order to detect microhardness, globular-hollow forms of gold were mounted in epoxy specimen. In such a manner, optimum section of gold particles was obtained, necessary for further study; it is possible to identify microhardness indices in its central part, end and shell. 55 identifications were performed at 12 sections of globular-hollow gold particles (Fig. 1 and Table 1). Since, gold fineness is increased in eolian conditions, high-standard shell is formed in end parts, and central parts remain unchanged; microhardness was measured in end parts of the globular-hollow gold, and in partition of hollow ball, being a relic of the flake.

3 Results and Discussion

Microhardness of native gold, being in eolian conditions, is studied for the first time. It is identified that, in four gold particles (1, 2, 3, 4), increase of microhardness from partition center to the end is clearly observed. Microhardness between individual grains of gold particles (1, 2) is 2 times different. Uniform microhardness is typical for different parts of the globular-hollow forms (6, 7, 9). Sample 12 yields increase of microhardness from outer part of the end to partition center. Other four gold particles do not have any clear regularity concerning microhardness distribution.

When microhardness of eolian gold was studied, it was found that, microhardness depends on degree of inner structure changes and chemical composition of gold in exogenetic conditions. When flaky gold is transformed in a complicated way into toroidal form, and then into globular-hollow form in eolian conditions, not only gold morphology is changed, but also chemical composition is changed, in particular gold fineness is increased and amount of trace elements is decreased (Nikiforova 1999). It is explained by the fact that, as a result of complicated transformation of flaky gold in eolian conditions, very thin gold films are stretched from the flake end and overlap each other, generating globular-hollow form. In this connection, surface for chemical impact is increased in exogenetic conditions, that contributed to gradual removal of silver and trace elements, and sharp decrease of microhardness indices of eolian gold.

In addition, earlier unknown lower limit of microhardness of the globular-hollow gold is identified - 21 kg/mm2.

In general, it is true that microhardness of eolian gold relatively low in comparison with native gold from other exogenetic conditions. It may be that, low microhardness is due to decompaction of some parts of the shell and the end of globular-hollow gold. Petrovskaya (1973) identified that, structures of recrystallization cause decompaction, stress relief, removal of silver and trace elements, that lead to increase of gold fineness up to 1000‰. Structures of decompaction, high fineness and paucity of trace elements are observed in the studied gold, that is why microhardness indices of globular-hollow gold reached such low limits.

In addition, earlier unknown lower limit of microhardness of the globular-hollow gold is identified - 21 kg/mm2.

In general, it is true that microhardness of eolian gold relatively low in comparison with native gold from other exogenetic conditions. It may be that, low microhardness is due to decompaction of some parts of the shell and the end of globular-hollow gold. Petrovskaya (1973) identified that, structures of recrystallization cause decompaction, stress relief, removal of silver and trace elements, that lead to increase of gold fineness up to 1000‰. Structures of decompaction, high fineness and paucity of trace elements are observed in the studied gold, that is why microhardness indices of globular-hollow gold reached such low limits.

4 Conclusions

Thus, low microhardness – 21 kg/mm2 is identified in globular-hollow gold is identified for the first time. Identified patterns in nature, microhardness changes under mechanogenic and chemical process impact in eolian conditions, can be successfully used in gold metallurgy to produce gold alloys with very low microhardness.

References

Badalova RP, Nikolaeva EP, Tolkacheva LF (1968) Study of microhardness of minerals of the silver-gold series from gold deposits of Uzbekistan. “Physical features of rare-metal minerals and methods of their study” collected articles, Moscow, Nauka

Filippov VE, Nikiforova ZS (1988) Transformation of native gold particles during process of eolian impact. AN SSSR Report, vol 299, № 5, pp 1229–1232

Lebedeva SI (1963) Identification of microhardness of minerals. AN SSSR Publishing House, Moscow

Nikiforova ZS (1999) Typomorphic features of eolian gold. ZVMO, N5, pp 79–83

Petrovskaya NV (1973) Native gold. Nedra, Moscow

Popenko GS (1982) Mineralogy of fold from the Quaternary deposits of Uzbekistan, Tashkent, FAN

Acknowledgements

The work is implemented within scientific-research projects of Diamond and Precious Metal Geology Institute, Russian Academy of Sciences, project № 0381-2016-0004.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2019 The Author(s)

About this paper

Cite this paper

Nikiforova, Z. (2019). New Data on Microhardness of Placer Gold. In: Glagolev, S. (eds) 14th International Congress for Applied Mineralogy (ICAM2019). ICAM 2019. Springer Proceedings in Earth and Environmental Sciences. Springer, Cham. https://doi.org/10.1007/978-3-030-22974-0_26

Download citation

DOI: https://doi.org/10.1007/978-3-030-22974-0_26

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-22973-3

Online ISBN: 978-3-030-22974-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)