Abstract

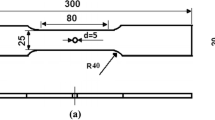

An experimental program has been carried out for the evaluation of the influence of the split sleeve expansion process on the fatigue crack growth in 2024-T351 aluminium alloy specimens. In previous ICAF Symposia, some information has been already given about the first part of the experimental activity (Helsinki 2015) and about the development of a numerical analysis method (Nagoya 2017). Both such preliminary papers referred to open hole specimens, tested under Constant Amplitude loading, while recently a pin loaded hole configuration has been evaluated. The non-inspectability of the configuration required some particular experimental effort, in order to collect test results in terms of crack growth as a function of number of cycles. To this end, a marker load technique was adopted: a block of high R ratio cycles (R = 0.9) was inserted in the R = 0.1 sequence, with the aim of obtaining information about the crack front evolution at different number of cycles.

Due to the three-dimensionality of the residual stress field, which is of lower intensity at the face of mandrel entrance, a 1 mm radius quarter-circular notch was inserted by means of EDM on the mandrel entry side face. Moreover, it was necessary to include also mechanically milled notches, of similar dimensions.

The results show a rather regular front evolution, and have provided important material for the development of accurate numerical methods, based on the evaluation of the residual stress field and on the subsequent modification of the stress intensity factor distribution along the corner crack front.

The numerical analysis methodology is a specialization of the technique, already presented in the Nagoya Symposium, to the problem of single or double corner crack in a pin loaded hole. In particular, the strong three-dimensionality of the stress field poses a challenge to the block-by-block propagation analysis.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Anon.: Abaqus 6.14 Analysis User’s Manual. Dassault Systemes Simulia Corporation, Providence, RI, USA (2014)

Boni, L., Fanteria, D., Lazzeri, L., Furfari, D.: Numerical prediction of fatigue crack propagation in cold-expanded holes. In: Proceedings of the 29th ICAF Symposium, Nagoya, Japan, 7–9 June 2017 (2017)

Lazzeri, L., Furfari, D., Fu, Q., Wetzel, A., Biasizzo, M.B., Busse, D.O.: Predicting fatigue crack growth emanating from cold-expanded holes. In: Proceedings of the 28th ICAF Symposium, Helsinki, Finland, 3–5 June 2015 (2015)

Newman Jr., J.C., James, M.A.: A crack opening stress equation for fatigue crack growth. Int. J. Fract. 24, 131–135 (1984). https://doi.org/10.1007/BF00020751

Newman Jr., J.C., Raju, I.S.: Prediction of fatigue crack-growth patterns and lives in three dimensional cracked bodies. In: Proceedings of the 6th International Conference on Fracture (ICF6), New Delhi, December 1984 1597–1608 (1984). https://doi.org/10.1016/b978-1-4832-8440-8.50151-4

Restis, J., Reid, L.: FTI process specification 8101D: cold expansion of holes using the standard split sleeve system and countersink cold expansion. Fatigue Technology Inc., Andover Park West, Seattle (WA), USA (2002).

Yue, J., Dong, Y., Guedes Soares, C.: An experimental-finite element method based on beach marks to determine fatigue crack growth rate in thick plates with varying stress states. Eng. Fract. Mech. 196, 123–141 (2018). https://doi.org/10.1016/j.engfracmech.2018.04.015

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Boni, L., Fanteria, D., Furfari, D., Lazzeri, L. (2020). Fatigue Crack Growth in Pin Loaded Cold-Worked Holes. In: Niepokolczycki, A., Komorowski, J. (eds) ICAF 2019 – Structural Integrity in the Age of Additive Manufacturing. ICAF 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-21503-3_49

Download citation

DOI: https://doi.org/10.1007/978-3-030-21503-3_49

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-21502-6

Online ISBN: 978-3-030-21503-3

eBook Packages: EngineeringEngineering (R0)