Abstract

Since Nb3Sn became available in the form of relatively long tapes in the early 1960s, it was considered for high-field magnets thanks to its high upper critical magnetic field and critical temperature. This chapter is a review of the effort accomplished by the community in the first 25 years of development of Nb3Sn accelerator magnets, and an attempt to understand why it took so long before this technology became successful.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

1 Introduction

Discovery and major advancements in the understanding and development of practical type II superconductors in the 1950s and 1960s made it possible to employ them in superconducting magnets, particularly, in accelerator magnets used for steering charged particle beams. The superconducting properties of Nb3Sn were discovered in the early 1960s, and soon it was available in form of tapes (or ribbons) produced by the surface diffusion process. Shortly afterwards an alternative concept based on solid-state diffusion was introduced. This principle has been used since the 1970s to fabricate Nb3Sn composite wires by the so-called bronze route. In 1974 the internal tin (IT) process was developed, which allowed overcoming the limitation of the bronze method to reach a high critical current density Jc due to the limited content of tin in bronze. The availability of IT composite wires eventually proved to be a key asset for high-field Nb3Sn magnet research and development (R&D) for accelerators. The year-by-year history of Nb3Sn wire development can be found in Foner and Schwartz (1981).

From the 1960s through the 1980s various teams set up programs in the USA, Europe, and Japan to develop Nb3Sn magnets as an alternative to Nb-Ti magnets in the 6–10 T field range. In those days, a field of 5–6 T was considered to be the maximum field attainable at 4.2 K in Nb-Ti magnets. It was known that the use of superfluid helium considerably boosts Nb-Ti performance. Complexity, reliability, and cost of superfluid helium cryogenic systems in the early 1980s suggested, however, that Nb3Sn magnets operated at 4.2 K could be a serious alternative to Nb-Ti magnets operated at 1.9 K for the 8–10 T field range. For this reason, various high-energy physics (HEP) laboratories around the world started exploring the feasibility of Nb3Sn magnets in the 8–10 T range for future colliders beyond the Tevatron (Edwards 1985), which was under construction at the Fermi National Accelerator Laboratory (FNAL , also known as Fermilab) from the late 1970s to the early 1980s. A more detailed historical overview of Nb3Sn conductor R&D for HEP, which found the limitations and provided breakthroughs for Nb3Sn accelerator magnet R&D programs, is presented in Chap. 2 of this book.

The effort in the USA was mainly concentrated at Brookhaven National Laboratory (BNL), along with Nb-Ti magnet R&D for the Intersecting Storage Accelerator (ISABELLE), later renamed the Colliding Beam Accelerator (CBA) project (cancelled in 1983) (Dahl et al. 1973), and later at Lawrence Berkeley National Laboratory (LBNL). In Europe, both the European Organization for Nuclear Research (CERN), Switzerland, which developed and operated the first low-beta superconducting quadrupoles in the Intersecting Storage Rings (ISR) (Billan et al. 1979), and the Commissariat à l’Energie Atomique (CEA), France, launched R&D programs for a possible hadron collider for the post-Large Electron–Positron (LEP) collider era. At the same time, the High Energy Accelerator Research Organization (KEK), Japan, also started a Nb3Sn-based program for accelerator magnets. Since it is beyond the scope of this chapter to account for all the efforts at those laboratories, we have selected a few endeavors to illustrate progress in an almost chronological order (our sincere apologies go to the projects not reported here). The main parameters of the projects described below are summarized in the table at the end of this chapter.

2 Nb3Sn Accelerator Magnets in the 1960s

2.1 First Nb3Sn Quadrupoles at BNL

The first Nb3Sn accelerator magnets were built at BNL in the middle of the 1960s, only a few years after the first Nb-Ti accelerator magnets. The magnets had a quadrupole configuration and were built using a Nb3Sn ribbon (in modern terminology, a tape) and the react-and-wind (R&W) method. The first Panofsky-type quadrupole model with square current blocks is shown in Fig. 3.1. It had a 30 mm bore and produced a field gradient of 100 T/m (Britton 1968). Despite the reasonable performance, this coil design was abandoned due to several deficiencies, e.g., the large field strength concentration in the coil corners, rather large coil ends and large end field errors, and the complicated coil winding technology. Even so, several quadrupoles of this type were fabricated.

Side (a) and end (b) views of the first BNL Nb3Sn quadrupole model with square current blocks. (Modified from Britton 1968)

The next BNL magnets were developed using a theoretical model based on current arrays or blocks placed around a circular or elliptical bore. The first quadrupole using this type of coil (also known as the shell-type coil) is shown in Fig. 3.2. It had a 76 mm bore and a 200 mm long straight section (Sampson 1967; Britton and Sampson 1967). Unfortunately, the details of magnet fabrication are not known at the present time. The magnet was tested in January 1966 and produced a maximum field gradient of 85 T/m at 630 A current, with a peak field on the walls of 3.2 T. The field was nearly two times higher compared to similar iron-dominated quadrupoles with water-cooled copper coils.

The shell-type Nb3Sn quadrupole. (Modified from Britton and Sampson 1967)

All the BNL models, except those with square blocks, used a 12.7 mm wide by 0.125 mm thick copper-plated ribbon (the thickness of the Nb3Sn layer was at least 0.075 mm). The available ribbon length varied between 300 and 950 m, which was sufficient to avoid internal splices. Typically, this ribbon carried 600 A at 4 T, which corresponded to a current density of 400 A/mm2.

The insulation of the Nb3Sn ribbons used in all the BNL beam magnets was either a thin stainless-steel tape for magnets with a stored energy above 10 kJ or, for smaller magnets, a varnish coating applied on the ribbon by the vendor.

Longer quadrupoles with wider apertures were also planned for a beam line doublet. The cross-section of a 100 mm aperture, 0.6 m long quadrupole is shown in Fig. 3.3. These magnets had to be wound with a better conductor to generate a coil peak field as high as 6 T. To our knowledge, however, the status and results of this work were never reported.

(a) The cross-section; and (b) a picture of the beam line Nb3Sn quadrupole coil (Modified from Britton and Sampson, 1967; Britton, 1968): 1 – Lorentz force constraining outer bands; 2 – mounting tube; 3 – pole block with lowest turn density; 4 – pole; 5 – wedge; 6 – screw to align wedge; 7 – mid-plane block with highest turn density

2.2 First Nb3Sn Dipoles for Synchrotron at BNL

In parallel with the quadrupoles, several dipole magnets were developed and constructed at BNL to study magnet quench performance and alternating current (AC) losses (Sampson et al. 1967). A 350 mm long dipole model with two flat racetrack coils separated by a 50 mm gap, and a dipole model with elliptical aperture were built and tested. Their cross-sections are shown in Fig. 3.4a, b. Figure 3.4c shows a cross-section of a real accelerator dipole with good field quality and field direction designed to be parallel to the ribbon face in the magnet straight section to take into consideration the Jc anisotropy in the ribbons. The magnets were made of 12.7 mm wide Nb3Sn ribbon, which provided the highest current density available at that time.

Cross-sections of: (a) Nb3Sn racetrack dipole coil; and (b, c) Nb3Sn shell-type dipole coil. (Modified from Britton 1968)

Pictures of racetrack and shell-type dipole models are shown in Fig. 3.5. These magnets were designed to be used in a synchrotron where the field had to be cycled with a period of 1–10 s. As in the case of the quadrupoles, the proper current distribution was simulated relatively easily using the current block model. The challenge was the prediction of the field level and the level of the AC losses during the expected fast cycling operation. Since multi-filamentary Nb3Sn composite wires with sufficient current density and small filament size were not yet available, the field quality and, especially, the power losses were a concern, when working with ribbons. The latter required the efficient removal of heat from the coil and increased the heat load on the cryogenic plant.

(a) BNL racetrack and (b) elliptical-aperture shell-type dipoles. (Modified from Sampson et al. 1967)

Results of the magnet quench performance tests for the racetrack and shell-type dipole models are not available. The AC loss measurements demonstrated that the losses were too high for operation in a synchrotron. Even for a relatively slow 10 s cycle, a refrigeration power of at least 20–100 W/m would have been required to remove the heat from the coils.

2.3 Nb3Sn Magnet Design Based on Braided Cable

Experimental and theoretical studies showed that to reduce the AC losses in superconducting accelerator magnets, high-current cables based on twisted multi-filament composite wires were needed. To address this issue, BNL developed a conductor based on braided cable, which became a distinctive characteristic of that laboratory for many years. The braid provided a complete transposition of many parallel strands, which, combined with the twisting of each single strand, drastically reduced the losses.

The first braid design was quite complex, see Fig. 3.6a. It had insulated fine Nb3Sn strands and smaller steel strands implemented for mechanical stability. It was expected that by weaving a braid with superconducting filaments of around 10 μm in diameter, a heat dissipation of less than 10 W/m would be achievable. Another version of the BNL braided cable that was later used in the Relativistic Heavy Ion Collider (RHIC) at BNL bus is shown in Fig. 3.6b.

(a) The first BNL braided cable concept from 1969 (modified from Sampson et al. 1969); (b) the 16.9 mm wide, 1.04 mm thick 97 strands braid used in the RHIC bus (courtesy of P. Wanderer, BNL)

The cross-section of the dipole model designed at BNL to test the new braided cable is shown in Fig. 3.7 (Sampson et al. 1969). It had four current blocks in each quadrant and was similar to the previous BNL shell-type magnets. The magnet was 300 mm long and had a circular aperture 50 mm in diameter.

Dipole design with braided cable (Modified from (Sampson et al. 1969): 1 – phenolic support rings; 2 – phenolic spacers; 3 – windings; 4 – non-magnetic beam tube

Initially, it was planned to wind the magnet with a high-current Nb3Sn ribbon to check field calculations and measure the end field distribution. Then, as soon as sufficient low-loss braided cable became available, it would be used in place of the conventional ribbon for the AC loss studies. It is not known if this dipole model was ever fabricated and tested (with ribbon or with braided cable).

3 Nb3Sn Magnet R&D in the 1970s

In the 1970s, BNL was working on 5 T Nb-Ti magnets for the ISABELLE 400 × 400 GeV proton–proton colliding beam facility. The first ISABELLE dipole design was based on a single-layer cos-theta coil with 130 mm aperture and a cold iron yoke of 457 mm outer diameter. The coil was made of a high aspect ratio superconducting braid with 97 composite Nb-Ti wires of 0.3 mm diameter filled (soldered) with a Sn-3wt%Ag alloy to provide mechanical rigidity. The cable was insulated with an epoxy-impregnated 0.05 mm thick fiberglass tape. The ISABELLE Nb-Ti dipole cross-section is shown in Fig. 3.8.

In parallel, it was decided to build and test similar dipole models, made of Nb3Sn braided cable using the R&W technique. It was expected that the thin, high aspect ratio Nb3Sn braid would ensure an acceptable degradation at the bends around the pole blocks. On the other hand, the R&W technique allowed the use of a standard cable insulation and a coil winding technology similar to those employed for Nb-Ti braid. Therefore, the idea was to substitute the Nb-Ti coil with a Nb3Sn one with virtually no change to the magnet design and assembly procedure. The use of Nb3Sn superconductor would be advantageous for ISABELLE, whose magnet cooling scheme was based on helium gas. To verify this idea, three 1 m long dipole magnets were constructed using reacted braided Nb3Sn cable (Sampson et al. 1977, 1979).

The braid was formed from 95 wires, each of 0.3 mm diameter and containing 1045 filaments of niobium in a Cu-10%Sn matrix surrounded by a pure copper layer. The latter was separated from the core by a tantalum diffusion barrier. After braiding and compacting, the cable was heat-treated in an inert atmosphere for 100 h at 700 °C to form Nb3Sn filaments. This heat treatment converted about 80% of the Nb to Nb3Sn, leaving a small niobium core. The braid was then filled with soft In+7%Pb alloy and insulated with glass–epoxy tape. During processing the braid was never subjected to bends smaller than 160 mm in radius.

The layout of the ISABELLE-type dipole coil is shown in Fig. 3.9. To reach the proper current distribution, a copper braid of identical size was wound as a spacer in parallel with the Nb3Sn braid. The number of such spacer braids varied from three in two blocks near the pole to none in the rest of the current blocks. The sharp transition bend at the coil pole was replaced with a shaped copper piece co-laminated with Nb3Sn tapes. This connection between the magnet halves was the weak point in the first magnet. The coil connection problem was solved in the next magnets by using short preformed pieces of braid soldered to the coils during magnet assembly. The resistance of this joint was about 1 nΩ.

In the pole turn, where the bending radius was minimal, a maximum strain of 4.6% was reached, which was almost an order of magnitude larger than typically accepted for Nb3Sn. The critical current degradation due to braid bending was compensated for by using parallel superconducting braids in the pole blocks instead of copper braids as in the first Nb3Sn coils. Thus, the current density in the pole blocks with the largest bending deformation was reduced by a factor of 3; and by a factor of 2 in the next current blocks, where the bending radius was somewhat larger.

For the remainder, the technology was very similar to that used for the Nb-Ti ISABELLE dipoles. The Nb3Sn coils were assembled with a split iron yoke and tested in a liquid helium bath. It was found that the braid degradation due to bending was consistent with expectations. The first magnet was, however, severely limited by heating in the resistive coil connection. At 2.5 kA, it dissipated about 10 W of Joule heating, which was beyond the value at which the heat starts propagating into the coil. The maximum coil current was 2.65 kA, or about 50% of the magnet short sample limit.

The next two magnets of this series were built with slight variations in the cable size and in the coil arrangement geometry. The latter dipole model was tested with coil cooling by high-pressure helium gas over a temperature range 4.2–15 K. At 4.2 K, the magnet reached a maximum bore field of 4.8 T, which was very close to the short sample limit. At higher temperatures, the magnet maximum field decreased approximately linearly with temperature. It is remarkable that at 8 K the field achieved in the magnet was still almost 4 T. This result shows that the magnet has realized its full potential. The successful test of this dipole magnet demonstrated further possibilities and important conditions for using the R&W technique for high-field Nb3Sn accelerator magnets.

4 Nb3Sn R&D in the 1980s

In the 1980s, various HEP laboratories started “conquering” the 8–10 T field region, to double the nominal magnetic field of the Tevatron and Hadron-Elektron-Ring-Anlage (HERA) projects. Nb3Sn multi-filamentary wires based on the bronze process were commercially available and produced in relatively large amounts at that time. The critical current density at 8 T and 4.2 K of bronze-route Nb3Sn wires was already slightly higher than that of Nb-Ti wires, and above 9 T Nb3Sn wires were clearly superior. In addition to a superior critical current density at 10 T and 4.2 K, the Nb3Sn bronze-route wires were very appealing thanks to their intrinsic small filament diameter of 2–3 μm, reducing the persistent current field errors for colliders and power losses for cycled synchrotrons with respect to Nb-Ti wires. A much higher critical temperature, together with superior intrinsic stability thanks to a small filament size, was also seen as a way to make more stable magnets less prone to quench.

An alternative approach was using traditional Nb-Ti magnets cooled by superfluid helium at 1.9 K. The critical current density curves of Nb-Ti wires at 1.9 K are shifted towards a higher field by about 3 T making feasible the use of Nb-Ti magnets for fields of 8–10 T at operating temperatures around 1.9 K. The complexity and the cost of superfluid helium cryogenics for operation at 1.9 K were such, however, at that time that Nb3Sn magnets operated at 4.2 K with all their technological difficulties and unsolved problems were still an attractive option to reach a target field range of 8–10 T.

The use of multi-strand Rutherford cables based on multi-filamentary composite wires, which after the Tevatron became the recognized standard for accelerator magnets, was an important element of the R&D toward 10 T dipoles and quadrupoles operating at 4.2 K. In addition, new types of Nb3Sn composite wires, based on the IT process, were explored to overcome the Jc limitation above 10 T. This eventually proved to be the key technology to enable high-field Nb3Sn dipole magnets well beyond the 10 T Nb-Ti uncontested reign.

4.1 The Nb3Sn Dipole at CEA-Saclay, 1983

At the early 1980s, the CEA laboratory in Saclay (France), which was strongly engaged in the development and construction of superconducting magnets for various projects such as the Russian Ускорительно-Накопительный Комплекс (UNK) (Accelerator and Storage Complex) and the German HERA, started an R&D program on Nb3Sn synchrotron magnets. A short dipole magnet was designed and manufactured using Nb3Sn Rutherford cable and the wind-and-react (W&R) technique (Perot 1983). To reduce costs and save time, the magnet design had to make use of the tooling and laminated collars that were available from the UNK Nb-Ti dipole models. Therefore, the coil geometry was predetermined and the bore field was limited to 6 T, based on the critical current density available at that time in Nb3Sn bronze composite wires. The aim of this project was not a record field, but rather exploring the Nb3Sn technology.

4.1.1 Conductor

The magnet coil used a Rutherford cable with 23 strands, each 0.7 mm in diameter. The cable was 7.8 mm wide and had a keystoned cross-section with a small edge of 1.2 mm and a large edge of 1.4 mm. The Nb3Sn cable geometry was identical to the cable of the previous Nb-Ti UNK dipole.

The strand was based on the copper-stabilized bronze-route Nb3Sn wire produced by the Magnetic Corporation of America (MCA). Each strand consisted of 4675 niobium filaments, each 3 μm in diameter, embedded in a bronze matrix. The bronze matrix was surrounded by a 0.017 mm thick tantalum barrier and a 0.070 mm thick outer ring of pure copper. The copper area was only 35% of the total strand area, thus the Cu/non-Cu ratio was only 0.54. More copper would be highly desirable for magnet quench protection, but it would decrease the wire’s average current density, losing any advantage with respect to Nb-Ti wires.

The cable was insulated by a 0.13 mm thick fiberglass tape wrapped with overlap. Cable reaction was kept at a relatively low temperature, compensated for by a rather long time (660 °C during 200 h in argon). The short sample critical current at 4.2 K was 7500 A at 6 T and 5700 A at 8 T.

4.1.2 Magnet Design and Manufacturing

The dipole featured two-layer coils, clamped by stainless-steel collars. The iron yoke was not a part of the magnet’s mechanical structure. The magnet had a 90 mm bore and was 0.64 m long. The relatively low current density of the Nb3Sn bronze wire and the predetermined size of the cable and the coil led to a moderate design field of 6 T for this Nb3Sn magnet. At the bore field of 6 T the magnet current was 6300 A and the stored energy was 100 kJ.

The two coil layers were wound separately on corresponding stainless-steel mandrels. Each layer was fitted in its own mold with some tolerance and then reacted. G10 end saddles and end pole pieces were installed during coil impregnation. Special care was paid to the cable insulation, which become very fragile after the sizing agent was removed, to the complex Nb3Sn/Nb-Ti joints manufactured within the impregnated coil, and to the connections among the coils by means of flexible Nb-Ti cables.

After impregnation, the coil layers were assembled together to form a pole. The upper and lower poles were then surrounded by ground insulation and precision collars. Figure 3.10 shows two impregnated coils ready for collar installation. The coil collaring procedure was the same as for Nb-Ti dipoles. This procedure provided precise conductor placement, coil pre-stress, and support.

The key issue of the described design was magnet protection during a quench. With a copper matrix of only 35%, the maximum current density in the copper during a quench was about 2000 A/mm2, which was considered an excessive value for a standard quench protection system based on quench heaters and/or an external dump resistor. To provide fast energy extraction, a secondary coil made of copper Rutherford cable of the same size as the superconducting one was wound and installed between the collars and the iron yoke (see Fig. 3.11). The coupling was not perfect since the secondary coil was rather far from the main coil. Nevertheless, this approach was sufficient to extract up to 30% of the stored energy in the magnet.

Cross-section of the CEA Nb3Sn dipole (Modified from Perot 1983): 1 – collar; 2 – Nb3Sn dipole coils; 3 – secondary copper coil; 4 – warm iron yoke (around collared coil)

4.1.3 Test Results

A very conservative 100 K “hot-spot” temperature was targeted for this magnet. Limiting the maximum voltage to 650 V with the given magnet inductance, the time constant to satisfy the hot-spot temperature limit was only 50 ms. It was much shorter than the opening time of the mechanical breakers available at that time. Therefore, it was decided to equip the magnet with a superconducting switch, activated by a capacitor bank for a few milliseconds. The switch was tested before using it in the protection circuit. It quenched at a steady-state current of 5.50 kA, thus setting the limit for the magnet power system.

The Nb3Sn dipole quenched three times, at currents of 5.15, 5.16, and 5.35 kA. Then it went up to 5.55 kA, a current at which the switch quenched. The maximum bore field was 5.3 T while the coil peak field reached 6 T, or 85% of the magnet short sample limit. Despite the apparent success, the achieved field was not impressive since it was similar to the field of the Nb-Ti dipole. Today we remain with the question of why the dipole was not simply pushed up without the switch, accepting a hot-spot temperature of 200–300 K, as we do today (but, after 30 years of experience!) in modern Nb3Sn magnets. Such an experiment would be extremely interesting.

4.2 Nb3Sn Technology Development at CERN

In the early 1980s, the first superconducting accelerator magnets were successfully operated at CERN in the Intersecting Storage Rings (ISR). The eight Nb-Ti low-beta quadrupoles pushed the ISR to proton–proton collisions with record luminosity (Perin et al. 1979). Since they were only used in a steady-state regime, the coils were wound with Nb-Ti monolithic conductor, with a warm bore of about 170 mm and a peak field of about 5 T. It was then a natural choice for CERN to use Nb3Sn technology to develop quadrupoles of superior gradient and operating margin. Thanks to the experience with Nb-Ti low-beta quadrupoles, which were essentially exposed to heat depositions by radiation debris coming from collisions, the CERN team considered the larger temperature margin of Nb3Sn coils as a considerable advantage to increase reliability of the magnets in accelerator operation.

The work on the quadrupole was preceded by a technology-learning phase aimed at testing the conductor and coil technologies in solenoidal configuration, which is simpler than accelerator quadrupole magnets; meanwhile, the design of the quadrupole was worked out (Asner et al. 1981, 1983). During this work, valuable experience was gained in handling the delicate brittle superconductor and solving problems of insulation, reaction, and coil splicing.

4.2.1 Conductor

The cable cross-section is shown in Fig. 3.12. The cable was 1.1 mm thick and 2.2 mm wide. It was made by Vacuumschmelze in Germany. The superconducting strands were based on bronze-route multi-filamentary Nb3Sn composite wire, similar to that used in the CEA dipole. Differently from the CEA conductor, however, the CERN Nb3Sn wire had a smaller diameter of 0.4 mm vs. the 0.7 mm of the CEA wire. Supplementary stabilizing copper was added to the cable by three elements: two 0.4 mm diameter copper strands, and a central copper core 0.4 mm thick and 1.5 mm wide. To prevent contamination of the three stabilizing elements with tin during heat treatment, they were surrounded by a tantalum barrier and copper-clad. Both the copper and the superconducting strands were tinned on the surface to avoid tin depletion from the Nb3Sn strands. Thus, after reaction the copper outside the tantalum barrier became low conductivity bronze. To keep the cable current density high, the pure copper content was only 27.2% of the total metal cross-section (a Cu/non-Cu ratio of only 0.37). Each superconducting strand had 3721 twisted niobium filaments, each ~3 μm in diameter.

The Nb3Sn cable used in CERN Nb3Sn magnets. (Modified from Asner et al. 1983)

4.2.2 Coil Fabrication Technology

Small radii of curvature in the quadrupole magnet made the W&R approach the preferred choice for coil fabrication. Extensive cable insulation R&D ended with the choice of quartz glass with a residual content of the carbon sizing agent of less than 0.03% after heat treatment. Despite various tests, however, the quartz glass proved to be fragile and easily deteriorated during winding and coil handling. The solution was to wet the quartz glass with paraffin to reinforce the insulation during handling. Then, a special heat treatment cycle was used to remove the paraffin and, thus, reduce the carbon remains in the coil. The coil reaction cycle used at CERN is presented in Table 3.1.

The coil lead joints were made by placing the Nb3Sn cables between two Nb-Ti cables, yielding a joint resistance of less than 10 nΩ. Finally, after reaction, the coils were vacuum-impregnated with epoxy resin.

To test the whole coil technology a 0.5 m long solenoid with 23 mm bore and 90 mm outer diameter was built with the cable, insulation, and coil technology described above. The solenoid, tested at 4.2 K, went straightforwardly and repeatedly to its maximum current of 1370 A, corresponding to 8.75 T of peak field in the coil. Thanks to a positive strain effect, the solenoid maximum current was slightly above the expected short sample limit. This was an important demonstration of the developed coil technology in a real accelerator magnet.

4.2.3 Nb3Sn Quadrupole Design and Fabrication

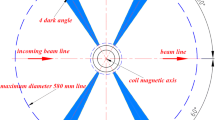

The Nb3Sn quadrupole design inherited CERN’s 10-year experience with Nb-Ti quadrupoles and dipoles for beam lines and low-beta triplets. The cross-section of the CERN Nb3Sn quadrupole is shown in Fig. 3.13. It consisted of an aluminum shrinking cylinder, spacer with helium channel, iron yoke, ground insulation, coil with copper pole block and two copper wedges, and cold support tube.

Cross-section of the CERN Nb3Sn quadrupole (Modified from Asner et al. 1983): 1 – aluminum shrinking cylinder; 2 – spacer with helium channel; 3 – iron yoke; 4 – ground insulation; 5 – copper pole block; 6 – inner coil block; 7 – copper wedge; 8 – outer coil block; 9 – cold support tube

The quadrupole length was 0.9 m and the aperture was 90 mm. To save cost and time, the structure and tooling were borrowed from the Nb-Ti quadrupole, at that time already operating in a secondary beam line of the Super Proton Synchrotron (SPS) at CERN (also known as the “Castor” quadrupole).

The coils were divided in two blocks, the one near the pole containing 60 turns and the one near the mid-plane containing 160 turns. Each coil was wound on a thick stainless-steel cylinder. The pole blocks and wedges, made of copper and insulated with Al2O3, were fixed to the winding mandrel. The pole blocks were split axially to allow for different thermal expansion and contraction between the coil and tooling during reaction and impregnation.

The copper end blocks were installed in place after winding. The lateral stainless-steel bars and grids were added with clearance to confine the coil before reaction. After reaction, each Nb3Sn lead was sandwiched between two Nb-Ti conductors and soldered using indium solder. The coil, surrounded with additional fiberglass and polyimide ground insulation, was impregnated in a precise mold to achieve an accurate geometry.

Four impregnated coils were assembled onto the 10 mm thick 316LN stainless-steel tube acting as the radial inner support and inner helium enclosure. The coils were then surrounded with radial spacers with helium channels. Two iron half-rings with a cut in the pole region formed the flux return yoke. At the coil ends the iron half-rings were replaced by stainless-steel ones to reduce the magnetic field in the coil ends. A cold iron yoke, introduced at CERN in 1973, became a trademark of CERN, providing field enhancement and compactness.

Coil azimuthal and radial preloads were delivered by an external clamping cylinder made of an aluminum alloy. To apply the pre-stress, the cylinder had a slightly smaller inner diameter and was heated and shrink-fitted around the iron halves. The mechanical structure described provided coil target compression to about 65 MPa at 4.2 K. With the applied electromagnetic forces the coil compression in the pole regions reduced to 20 MPa. The maximum azimuthal and radial stresses in the coil were selected to be acceptable for brittle Nb3Sn coils.

In the axial direction, the coil preload was applied by means of spring-loaded screws attached to the inner stainless-steel tube. This approach allowed for compensation of the differential thermal contraction between the stainless-steel tube and the coil, and partially counterbalanced the electromagnetic forces in the coil ends.

4.2.4 Quadrupole Test Results

The quadrupole was tested in 1981 at 4.2 K without the protection resistor, since the stored energy was 100 kJ, which is relatively small. The measured resistances of the Nb3Sn/Nb-Ti connections were comfortably low, between 20 and 50 nΩ. The first quench occurred at a nominal current of 1.0 kA, and in four quenches the current reached its maximum value of 1.1 kA, which was within 93–99% of the magnet short sample limit based on witness sample tests. The corresponding maximum field gradient was 70.5 T/m (compared to 55 T/m of the Nb-Ti Castor quadrupole) and the maximum field in the coil was 7.8 T.

The quadrupole was tested again in 1982 after shunting of each coil with a 50 mΩ protection resistor. The magnet went straight up to a current of 1.1 kA, confirming that the maximum current was effectively reached. Magnetic measurements showed a reasonable field quality. The deviations from ideal field harmonics were in the range 20–70 units.

This program successfully validated the Nb3Sn wire and cable, and the W&R technology developed at CERN for accelerator magnets. This success (as well as the results of CEA) provided a strong base for CERN’s next project to build a 10 T Nb3Sn accelerator dipole. This magnet was successfully developed and tested at the end of the 1980s (Asner et al. 1990).

4.3 Nb3Sn Dipole at LBNL

LBNL undertook the development of a 10 T dipole based on a Nb3Sn conductor (Taylor and Meuser 1981; Taylor et al. 1983, 1985). This development was carried out in parallel with the Nb-Ti magnet R&D for the Superconducting Super Collider (SSC).

4.3.1 Main Design Concept

To produce a cost-effective dipole design, a small bore of 50 mm and a high field of 10 T were chosen as initial design parameters. Analysis of magnets with these parameters showed that a high critical current density of about 1200 A/mm2 at 4.2 K and 10 T was required.

These parameters had a strong influence on the conductor choice: (a) the bronze route for Nb3Sn wires was abandoned since it was at least 20–30% short of the critical current density needed. Instead, the development and scale-up of the IT approach for Nb3Sn high critical current density wires became an important part of this program; (b) the conductor had to carry a large current to reduce inductance and magnet discharge time; (c) due to the small coil diameter, the W&R technique was considered for coil fabrication.

A cross-section of the LBNL 10 T dipole is shown in Fig. 3.14. The coil consisted of four racetrack windings per pole, each layer having different winding diameters and thicknesses, to mimic a shell cos-theta configuration. The coils were not graded and used the same Rutherford cable with a rectangular cross-section. The coils featured flared ends to clear the bore. The inner tube, needed for structural reasons, reduced the useful bore to 40 mm from the 60 mm coil aperture. The magnet was assembled without an iron yoke. The coil was clamped to a high pre-stress to avoid separation from the structure under the Lorentz forces. An advantage of this configuration is that the maximum stress at high fields occurs in the low-field regions and, therefore, it is less prone to degradation due to strain in the Nb3Sn filaments. Calculations of the stress at 10 T in this dipole predicted an average compressive stress of 83 MPa along the mid-plane, and local compressive stresses of over 138 MPa.

Cross-section of the LBNL Nb3Sn dipole (Modified from Taylor et al. 1983): 1 – stainless-steel stud; 2 – brass spacer; 3 – aluminum clamp; 4 – stainless-steel bearing plate; 5 – stainless-steel winding form; 6 – fiberglass epoxy; 7 – stainless-steel side plate; 8 – coil; 9 – stainless-steel end plate

4.3.2 Conductor

The main novelty of this program was the use of IT Nb3Sn composite wire, produced using a new process, in those years still in its early stage compared to the much more mature bronze route. A Nb3Sn composite wire with the following specifications was ordered at Intermagnetics General Corporation (IGC): strand diameter 1.7 mm, 50% copper, and a target Jc(10 T) of 1200 A/mm2. This Nb3Sn wire was used to produce 300 m of an 11-strand Rutherford cable.

The cable cross-section is shown in Fig. 3.15. Dimensions of the uninsulated cable were 11.0 mm by 3.0 mm. The cable was compacted to around 80% and the minimum Jc(10 T) after cabling was 975 A/mm2. After fabrication, the cable was annealed at 200 °C for 3 h to soften the copper and facilitate winding. Presumably, the main causes of the large Jc degradation allowed due to cabling were the large strand diameter (more than double what was used at that time for other accelerator magnets) and the higher sensitivity of the IT wires to stress.

Rutherford cable for LBNL Nb3Sn dipole. (Modified from Taylor et al. 1985)

4.3.3 Magnet Construction

The magnet was composed of four double-pancake coils, and each coil was wound from a single piece of cable. The cable was insulated on-line during coil winding with an S-glass tape. The tape was 11.3 mm wide and 1.625 mm thick, wrapped onto the cable with 50% overlap.

A winding base with a straight section and ends sloped downward at 10° was mounted on a winding table, and the stainless-steel pole pieces were attached to this base. Three layers had 14 turns while the fourth layer had 11 turns. After winding, the remaining sides and ends of the stainless-steel coil forms were assembled around the coils. The coils were compressed an average of 1.2% from the slightly clamped dimensions.

The reaction cycle consisted of four steps: 200 h at 200 °C, 24 h at 375 °C, 240 h at 500 °C, and 100 h at 700 °C. After reaction, some change of the insulation color was seen, but the turn-to-turn insulation remained adequate and the insulation showed no signs of deterioration. No tin leakage was found at the ends of the strands.

Prior to potting, Nb-Ti cable leads were spliced onto the Nb3Sn cable leads. The splice joint was made over the 500 mm long straight section using 62 wt% Sn, 2 wt% Ag, and 0.35% Sb balance Pb solder alloy. Before potting, aluminum forms sealed with rubber rings were installed and the coil was pumped in a vacuum chamber. After baking for 12 h, epoxy was introduced into the coil and cured at 50 °C for 5 h, 60 °C for 8 h, and 80 °C for 8 h. The epoxy was a mixture of 50 parts Epon 826 and 50 parts DER 736, catalyzed with 25 parts Tonex. The picture of a D10 dipole coil is shown in Fig. 3.16.

The potted layers were installed on each side of a stainless-steel bore tube insulated with a 0.25 mm thick layer of bi-axially oriented polyethylene terephthalate (Mylar). Coil compression was provided with stainless-steel side plates and top and bottom aluminum bars. The assembly was clamped to achieve a moderate horizontal compression of 34 MPa, chosen for initial testing to avoid possible damage to the Nb3Sn coils. After the assembly, clamps were removed and the coil compression decreased to about 17 MPa. Note that these numbers are significantly smaller than those produced by the Lorentz forces.

Because of the long lead time to develop and procure the IT Nb3Sn wire, a Nb-Ti magnet, called D10B, was built to validate the process and the technology, in particular the design chosen for the flare ends (Gilbert et al. 1983). The magnet was designed to produce a 10 T dipole field in a 40 mm diameter bore. The Nb-Ti cable was half as thick as the Nb3Sn cable, and thus the Nb-Ti dipole operated at half the operating current of the Nb3Sn dipole. The Nb-Ti model, tested at 1.8 K, allowed direct comparison between the two conductor technologies.

4.3.4 Test Results

The Nb-Ti D10B dipole was tested at 4.2 K and then at 1.8 K. At 4.2 K, magnet training started at 80% of the short sample limit. The magnet short sample limit was reached after about 25 quenches, producing a central bore field of 7 T. The magnet was then cooled to 1.8 K, and it reached its short sample limit (within a few percent) in a dozen quenches, providing a central field of 9.1 T (almost 10 T coil peak field).

The Nb3Sn magnet was tested at 4.2 K at a current ramp rate of about 60 A/s, equivalent to 0.04 T/s in the magnet bore. Magnet training started at 7 T and proceeded at a reasonable rate to 8 T after 15 quenches. The quenches were distributed over all layers and did not start at the inner turns exposed to the highest field. At the 16th quench at 12 kA (bore field of 8 T), the extraction system failed and all the stored energy was dumped into the magnet. Afterwards, the maximum quench current was around 300 A lower. Quenches in superfluid helium at 1.8 K were at the same current, indicating that the magnet did not reach its short sample limit. The observed limitations were associated with conductor motion or heating in the Nb3Sn/Nb-Ti splices. The available instrumentation was not sufficient to disentangle the issue.

In principle, D10 was a successful magnet. The coil technology based on the W&R approach and impregnation with epoxy as well as the strong mechanical structure was proved to work. The IT approach was capable of producing long lengths of high-quality Nb3Sn composite wire. The direct comparison with the Nb-Ti dipole of similar design, which reached a higher field, clearly indicated that the Nb3Sn technology was still far from being mature or even usable. This dipole was, however, among the most innovative Nb3Sn accelerator magnets concerning the conductor and the mechanical structure. In particular, the development of IT Nb3Sn wire was a fertile seed for future magnet programs.

4.4 Nb3Sn Magnet R&D at KEK, Japan

At the end of the 1970s and the start of the 1980s, development and studies of accelerator magnets based on Nb3Sn superconductor were also performed in Japan. It is remarkable that the Japanese magnet R&D program, in parallel with the bronze Nb3Sn wires, started using new IT-type composite wires developed by Japanese industry to overcome the intrinsic Jc limitations of the bronze-route wires.

4.4.1 KEK-Toshiba Small-Scale Nb3Sn Dipole (1980)

A small 0.35 m long dipole with a free bore of 62 mm was designed, manufactured, and tested by a collaboration between KEK and the Toshiba Research and Development Center (Ishibashi et al. 1981). To our knowledge, it was perhaps the first direct involvement of industry in Nb3Sn accelerator magnet R&D.

The conductor, produced by the Showa Electric Wire and Cable Company, was a rectangular monolithic wire, 2 mm wide and 1 mm thick, with 258 niobium tubes filled with tin and distributed in a copper matrix (Murase et al. 1979). The conductor cross-section is shown in Fig. 3.17. The geometrical diameter of the niobium tubes was 60 μm. At the end of the reaction, the pure copper fraction was 0.635, which corresponds to a fairly high Cu/non-Cu ratio of more than 1.7. The conductor had a relatively low critical current density, a non-Cu Jc of 1600 A/mm2 at 4.2 K and 5 T, which would yield just above 600 A/mm2 at 10 T. This test was intended to prove the conductor and magnet fabrication technology, rather than to achieve a record field.

Cross-section of the IT Nb3Sn conductor for the KEK-Toshiba small scale dipole. (Modified from Ishibashi et al. 1981)

The coil construction technology was based on the W&R approach. The conductor was insulated with E-glass insulation, whose sizing agent was removed with an intermediate heat treatment. The tin diffusion process was rather slow, requiring a heat treatment of 790 h at 700 °C.

The four coils were arranged in two pairs of shell layers with constant current density. The cos-theta current distribution was approximated by optimizing the azimuthal extension of the coil layers. Each shell layer was composed of four layers of conductor winding. Due to a small conductor cross-section, this magnet had 408 turns and a large inductance of 24 mH. Each coil shell was reacted and epoxy impregnated. Afterwards the coils were assembled on a stainless-steel mandrel with an inner diameter of 62 mm, and covered with an insulation layer. An aluminum cylinder was heated and shrink-fitted around the coil. A cross-section of the magnet assembly is shown in Fig. 3.18.

Cross-section of the small-scale KEK-Toshiba Nb3Sn dipole (Modified from Murase et al. 1979): 1 – aluminum pipe; 2 – epoxy impregnated glass tape; 3 – SUS 316 L stainless-steel pole blocks; 4 – coil inner layer; 5 – coil outer layer; 6 – SUS 304 L stainless-steel support tube; 7 – cooling channel

The magnet was tested at 4.2 K, and started quenching at very low field, reaching a plateau after seven quenches at 3.5 T, which corresponded to 88% of the magnet short sample limit. Based on investigations, the rather small radius of the inner layer pole and heating in the joints were ruled out as a possible cause of the critical current degradation. Therefore, only mechanical degradations remained as a possible explanation, without any other precise indication.

4.4.2 The KEK Effort Toward a 10 T Dipole

To explore the 10 T dipole field region, two development paths were explored at KEK in the first part of the 1980s (Hirabayashi 1983), similar to what occurred in the same years at LBNL and at CERN. One path was the investigation of the performance of Nb-Ti magnets cooled by pressurized superfluid helium. The other path was devoted to developing the design and manufacturing technology for an accelerator-quality dipole using Nb3Sn bronze conductor.

A 10 T Nb3Sn multi-shell dipole was designed with a layout of three pairs of double-shell coils, see Fig. 3.19. The angle and thickness of each pair was adjusted to generate an accurate dipole field in the magnet aperture. Each layer was graded to maximize the current density using conductors with optimal keystone angles.

Cross-section of the KEK six-layer Nb3Sn dipole (Modified from Hirabayashi 1983): #1–6 – coils; 1–3 – stainless-steel collars

The monolithic multi-filamentary Nb3Sn conductors were manufactured using the bronze route. Each conductor had a pure copper content of 30–40%. The design value of the central field was 10 T at a magnet current of 5.16 kA, and the magnet maximum stored energy was 959 kJ/m. The detailed parameters of the various layers and their conductors are reported in Yan et al. (1987).

To develop and test the technology for Nb3Sn accelerator magnets, a single-layer racetrack magnet and a double-shell dipole model (coils #3 and #4) were built and tested. Based on the experience gained from those two magnets, a second double-shell dipole (coils #5 and #6) was also constructed and tested. The program was based on the W&R approach. All of the magnets were manufactured with bronze conductors produced by the Furukawa Electric Company.

4.4.3 R&D Racetrack as Intermediate Step

An R&D racetrack magnet was designed, manufactured, and tested as an intermediate step. This magnet (Mito et al. 1984) was almost 1 m long (800 mm long straight section) and had 30 turns. The monolithic rectangular conductor was 2.3 mm thick and 6.0 mm wide, similar to that designed for layer #2. Its critical current was 11.7 kA at 4.65 T and 4.2 K. The conductor was insulated with a mica-glass composite, a new insulation type that was later used in some Nb3Sn magnets. After reaction, the coil was not impregnated with epoxy to allow direct helium cooling as a mean of coil thermal stabilization.

The magnet was tested in a vertical cryostat. After a first quench at 5.3 kA, it reached the power supply limit of 7.0 kA, which was about 80% of the magnet short sample limit. A second training campaign after improvement of the end support was, however, limited by quenching at 6.82 kA. The reason was attributed to conductor movement in the coil ends due to insufficient support.

4.4.4 Double-Layer Dipole Test

A double-layer dipole was assembled, as described above, with coils #3 and #4 (see Fig. 3.19). The coil pre-stress was applied by compression of the iron yoke. The magnet had a 132 mm diameter bore and a 400 mm long straight section. The total magnet length was 870 mm. The iron yoke had a 184 mm inner diameter and a 348 mm outer diameter. The cross-section of the KEK double-layer dipole is shown in Fig. 3.20, and a picture of the magnet is shown in Fig. 3.21.

Cross-section of the KEK double-layer Nb3Sn dipole (Modified from Hirabayashi and Tsuchiya 1986): 1 – stainless-steel collar; 2 – G10 insulation; 3 – dipole coils; 4 – G10 bore tube; 5 – iron yoke

The double-layer dipole with coils #3 and #4 was tested twice. During the first test eight quenches occurred, and during the second one 25 quenches occurred. A relatively long training and a large degradation were observed during magnet tests. The maximum quench currents ranged from 4.2 to 5.6 kA, whereas the magnet’s short sample limit was about 10 kA. Thus, the magnet reached only 3.8 T (the maximum field in the coil was about 4.5 T), which was about 56% of the expected short sample limit. It was concluded that conductor motion and the joints were not acceptable, indicating that further improvements were required.

Comparison of the test results of the racetrack magnet and the double-layer dipole with coils #3 and #4 suggested that conductor motion was the main cause for the training and degradation of both these magnets, although the racetrack magnet showed better performance than the double-shell dipole.

With all the experience accumulated on the racetrack and the first double-layer shell-type dipole magnets, another dipole model was assembled with coils #5 and #6 (the outer double-layer in Fig. 3.19) in a similar mechanical structure, but with a larger aperture of 186 mm. The coils had a 400 m long straight section and were first wound in a flat racetrack shape and then pressed to form the shell-type coils desired. Two layers of 0.13 mm thick mica-glass tape provided the conductor insulation in the magnet. After heat treatment at a temperature of 700 °C for 48 h, the coils were assembled, compressed, and clamped by stainless-steel collars. Coils #5 and #6 were not impregnated with epoxy to allow direct contact of liquid helium with the conductor, as for coils #3 and #4.

The test of the double-layer magnet with coils #5 and #6 showed even poorer quench performance. The magnet maximum current was about 3 kA, which corresponded to a bore field of about 2.9 T, or less than half of the 7.3 kA magnet short sample limit. One of the possible reasons was damage to the conductor during coil fabrication and magnet assembly.

Many tests were carried out on those magnets to study their stability and quench properties. The cooling effect was found to be small, with measurements being in good agreement with the adiabatic models. The results above led to the main conclusion that coil impregnation with epoxy was mandatory to avoid conductor motion and to protect the coils.

5 Nb3Sn Dipole for a Cable Test Facility at BNL (1991)

After various R&D activities, BNL made another attempt to use the R&W approach in a Nb3Sn dipole magnet approximately 1 m long with an 80 mm bore (McClusky et al. 1993). The magnet was intended to provide the background field for a cable test facility for the SSC and RHIC projects. To test the magnet construction techniques, Nb-Ti coils of identical dimensions were also built with the SSC cable.

The Nb3Sn magnet used a Rutherford cable made from Nb3Sn multi-filamentary composite wires. The cross-section of the coil is shown in Fig. 3.22. The coil featured four layers: each set of layers was separately constrained with aramid fiber (Kevlar) reinforced epoxy bands, and the complete coil assembly was pre-stressed by a horizontally split laminated iron yoke, 508 mm in diameter. The cross-section of the magnet is shown in Fig. 3.23. The yoke was fabricated from the standard ISABELLE/CBA blocks that were formed from thin low carbon steel laminations glued together under pressure.

Cross-section of the BNL Nb3Sn dipole coil. (Modified from McInturff et al. 1997)

Cross-section of the BNL Nb3Sn dipole (Modified from McClusky et al. 1993): 1 – iron yoke; 2 – pole block; 3 – spacer; 4 – coil

5.1 Conductor

The outer cable was made of a low-magnetization modified jelly roll (MJR) Nb3Sn composite wire (a special IT diffusion process) that was developed in the previous years for Nb3Sn solenoids. To our knowledge, this was the first use of MJR wires in accelerator magnets. Thanks to the high critical current density and relatively low cost, this type of Nb3Sn wire dominated the scene in the 1990s until the first years of the new century.

The inner cable was also made of a MJR-type wire with higher Nb3Sn content to allow for a very high overall current.

5.2 Coil Fabrication

The four-layer coil was fabricated in pairs using the double-pancake technique to eliminate internal joints. The two inner layers were manufactured using the W&R technique to avoid conductor degradation during winding around narrow poles. The two outer layers were manufactured using the R&W technique, which was considered to be safe due to the wide poles.

The Nb3Sn cable for the outer layers was treated with Mobil-1® synthetic oil before reaction to avoid strand sintering, and heat-treated on a 1 m diameter stainless-steel drum with alumina–paper separators. The outer layer cable was insulated with polyimide and B-stage epoxy–fiberglass insulation, and the outer coils were molded in a high-pressure fixture.

The inner layer cable was insulated by a 10 mm wide and 0.1 mm thick S-glass tape wrapped with 50% overlap, providing a total insulation thickness of 0.2 mm. The inner coils were reacted as wound in a special fixture, which maintained their shape during reaction. The inner coils were given the same heat treatment as the cable used in the outer coils. A low-pressure argon atmosphere was maintained in the furnace during the four-step reaction cycle: 200 h at 220 °C, 48 h at 340 °C, 24 h at 580 °C, and 150 h at 650 °C.

Both inner and outer coils were not impregnated with epoxy to get the maximum benefit from helium cooling, similar to the Japanese R&D program described above.

5.3 Magnet Assembly

After assembly, the coils were clamped onto an inner stainless-steel tube with 25 mm thick aluminum rings, spaced by 50 mm. Kevlar–epoxy composite wire was wound between the aluminum blocks to apply pre-stress to the coils. Once the Kevlar–epoxy composite was cured, the aluminum rings were removed and their space filled again with the same Kevlar–epoxy composite to apply pre-stress to these sections. The outer radius of the Kevlar–epoxy banding was then machined to fit exactly the inner diameter of the yoke. The yoke pre-stressed the coils by means of bolts and supported the Lorentz forces during magnet excitation. The coils were connected in series by pre-shaped Nb-Ti cables, located at the end of the magnet in a low field region.

5.4 Test Results

The short sample bore field of the Nb-Ti dipole was 7.8 T at 3.5 kA, while the short sample limit of the Nb3Sn dipole was 9.8 T at 5.15 kA. The first quench in the Nb-Ti dipole occurred at 3.1 kA (7 T bore field, 7.3 T peak field). After 15 quenches, the magnet reached its maximum current of 3.5 kA, corresponding to a bore field of 7.8 T and a peak field in the coil of 8.27 T.

The first quench of the Nb3Sn dipole occurred at approximately 4 kA (the bore field 7.6 T, the coil peak field 8.0 T), i.e., at nearly 80% of the expected short sample limit. During subsequent training at the fourth quench (the first one occurred in the inner coils) at 4.35 kA something happened, and from there on the magnet was limited to less than 4 kA. By measuring the decay rate while in the persistent mode, a significant field-dependent resistance was found in the windings. Disassembly of the coils could not reveal any damage. It was observed, however, that the inner coil was detached from the pole by more than 2 mm!

It is interesting that in the original paper the magnet’s performance was considered disappointing. The reason for the disappointment was the resistance developed in the coil at relatively low currents. Today it is clear that this was due to the choice of using non-impregnated coils. The large 2 mm displacement of the coil pole turns from the poles also indicated that the coil pre-stress was less than adequate. Perhaps this displacement would have been smaller and would have had less impact on magnet performance if the coils had been impregnated. While the helium was of little help for stabilization, as also concluded by the KEK program, the lack of good thermal conduction may have had a detrimental effect during quench, constraining transverse heat propagation.

6 Conclusion

This review covered the first 25 years of Nb3Sn accelerator magnet R&D, which started in the USA and was then quickly taken up in Europe and Japan. The key design and performance parameters of the magnets described above are summarized in Table 3.2.

The development of Nb3Sn accelerator magnet technology proceeded in parallel with Nb-Ti accelerator magnets, which made steady progress and quickly filled all the field space up to their limit of 10 T, thanks to the development of large superfluid helium refrigerators and cooling technologies that were affordable and reliable. During the same period of time Nb-Ti accelerator magnet technology made quick progress from short model magnets, throughout technology scale-up, to mass production and use in large accelerators and colliders such as the Tevatron, HERA, and RHIC.

On the contrary, the progress of Nb3Sn accelerator magnet technology was very slow, being restricted by a limited number of short technological models and demonstrating very volatile results. Nevertheless, these initial R&D efforts on Nb3Sn accelerator magnets were not useless. Indeed, various types of Nb3Sn wires and cables, shell-type and block-type coils, R&W and W&R techniques, various support structures, and coil preload concepts were tested, and the first knowledge of Nb3Sn magnet performance was obtained. Finally, at the beginning of the 1990s, the first Nb3Sn dipole magnets to break the 10 T wall were built and tested (Asner et al. 1990; den Ouden et al. 1997; McInturff et al. 1997). These exciting results paved the way towards new, previously unattainable, fields for accelerator magnets. The results of these works are presented and discussed in the next chapters of this book.

References

Asner A, Becquet C, Hagedorn D et al (1981) Development and testing of high field, high current density solenoids and magnets, wound with stabilized filamentary Nb3Sn cable and reacted after winding. IEEE Trans Magn 17(1):416–419. https://doi.org/10.1109/tmag.1981.1061064

Asner A, Becquet C, Rieder H et al (1983) Development and successful testing of the first Nb3Sn wound, in situ-reacted, high-field superconducting quadrupole of CERN. IEEE Trans Magn 19(3):1410–1416. https://doi.org/10.1109/tmag.1983.1062338

Asner A, Perin R, Wenger S et al (1990) First Nb3Sn, 1m long superconducting dipole model magnets for LHC break the 10 Tesla field threshold. In: Sekiguchi T, Shimamoto S (eds) 11th international conference on magnet technology (MT-11), vol 1, Tsukuba, 28 Aug–1 Sep 1989. Springer, Dordrecht, pp 36–41

Billan J, Henrichsen KN, Laeger H et al (1979) A superconducting high-luminosity insertion in the intersecting storage rings (ISR). IEEE Trans Nucl Sci 26(3):3179–3181. https://doi.org/10.1109/tns.1979.4329976

Britton RB (1968) Brookhaven superconducting DC beam magnets. In: Prodell AG (ed) 1968 BNL school on superconductivity June 10–July 1968, BNL. Upton, New York, pp 893–907

Britton RB, Sampson WB (1967) Superconducting beam handling equipment. IEEE Trans Nucl Sci 14(3):389–392

Dahl PF, Damm R, Jacobus DD et al (1973) Superconducting magnet models for Isabelle. IEEE Trans Nucl Sci 20(3):688–692. https://doi.org/10.1109/TNS.1973.4327216

Den Ouden A, Wessel S, Krooshoop E et al (1997) Application of Nb3Sn superconductors in high-field accelerator magnets. IEEE Trans Appl Supercond 7(2):733–738. https://doi.org/10.1109/77.614608

Edwards HT (1985) The Tevatron energy doubler: a superconducting accelerator. Annu Rev Nucl Part Sci 35(1):605–660. https://doi.org/10.1146/annurev.ns.35.120185.003133

Foner S, Schwartz BB (1981) Superconductor material science. Plenum Press, New York. (chapter 4, p 201)

Gilbert W, Caspi S, Hassenzahl W et al (1983) 9.1 T iron-free Nb-Ti dipole magnet with pancake windings. IEEE Trans Nucl Sci 30(4):2578–2580. https://doi.org/10.1109/tns.1983.4332888

Hirabayashi H (1983) Dipole magnet development in Japan. IEEE Trans Magn 19(3):198–203. https://doi.org/10.1109/tmag.1983.1062355

Hirabayashi H, Tsuchiya K (1986) Superconducting dipole and quadrupole magnets in KEK. KEK Preprint 86–25, June 1986

Ishibashi K, Koizumi M, Hosoyama K et al (1981) Nb3Sn dipole magnet by wind and react process. IEEE Trans Magn 17(1):428–431. https://doi.org/10.1109/tmag.1981.1061080

McClusky R, Robins KE, Sampson WB (1993) A Nb3Sn high field dipole. IEEE Trans Magn 27(2):1993–1995. https://doi.org/10.1109/20.133596

McInturff AD, Benjegerdes R, Bish P et al (1997) Test results for a high field (13 T) Nb3Sn dipole. In: Comyn M, Craddock MK, Reiser M et al (eds) Proceedings of the 1997 particle accelerator conference (Cat. No.97CH36167), Vancouver, 12–16 May 1997, IEEE, Piscataway, vol 3, pp 3212–3214

Mito T, Tsuchiya K, Hosoyama K et al (1984) A single-layer race-track magnet using a niobium-tin conductor. Adv Cryo Eng 29:79–86. https://doi.org/10.1007/978-1-4613-9865-3_9

Murase S, Koizumi M, Horigami O et al (1979) Multifilament niobium-tin conductors. IEEE Trans Magn 15(1):83–86. https://doi.org/10.1109/tmag.1979.1060198

Perin R, Tortschanoff T, Wolff R (1979) Magnetic design of the superconducting quadrupole magnets for the ISR high luminosity insertion. Internal report CERN ISR-BOM 79–02, CERN, Geneva

Perot J (1983) Construction and test of a synchrotron dipole model using Nb3Sn cable. IEEE Trans Magn 19(3):1378–1380. https://doi.org/10.1109/tmag.1983.1062270

Sampson WB (1967) Superconducting magnets for beam handling and accelerators. In: Hadley H (ed) Proceedings of the second international conference on magnet technology (MT-2), 11–13 July 1967, The Rutherford Laboratory, Oxford, Chilton, pp 574–578

Sampson WB, Britton RB, Morgan GH et al (1967) Superconducting synchrotron magnets. In: Mack RA (ed) Sixth international conference on high energy accelerators, 11–15 Sep 1967. Cambridge Electron Accelerator, Cambridge, pp 393–396

Sampson WB, Britton RB, Morgan GH et al (1969) Superconducting synchrotron magnets. IEEE Trans Nucl Sci 16(3):720–722. https://doi.org/10.1109/tns.1969.4325342

Sampson WB, Suenaga M, Kiss S (1977) A multifilamentary Nb3Sn dipole magnet. IEEE Trans Magn 13(1):287–289. https://doi.org/10.1109/tmag.1977.1059452

Sampson WB, Kiss S, Robins K et al (1979) Nb3Sn dipole magnets. IEEE Trans Magn 15(1):117–118. https://doi.org/10.1109/tmag.1979.1060162

Taylor CE, Meuser RB (1981) Prospects for 10 T accelerator dipole magnets. IEEE Trans Nucl Sci 28(3):3200–3204. https://doi.org/10.1109/tns.1981.4332052

Taylor C, Meuser R, Caspi S et al (1983) Design of a 10 T superconducting dipole magnet using niobium-tin conductor. IEEE Trans Magn 19(3):1398–1400. https://doi.org/10.1109/tmag.1983.1062261

Taylor C, Scanlan R, Peters C et al (1985) A Nb3Sn dipole magnet reacted after winding. IEEE Tran Magn 21(2):967–970. https://doi.org/10.1109/tmag.1985.1063680

Yan L, Tsuchiya K, Hirabayashi H (1987) Some results from the first test of the double-shell Nb3Sn dipole. KEK Report 87–14, Sep 1987, National Laboratory for High Energy Physics, Oho-machi, Tsukuba-gun

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2019 The Author(s)

About this chapter

Cite this chapter

Rossi, L., Zlobin, A.V. (2019). Nb3Sn Accelerator Magnets: The Early Days (1960s–1980s). In: Schoerling, D., Zlobin, A. (eds) Nb3Sn Accelerator Magnets. Particle Acceleration and Detection. Springer, Cham. https://doi.org/10.1007/978-3-030-16118-7_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-16118-7_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-16117-0

Online ISBN: 978-3-030-16118-7

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)