Abstract

Aquaponic systems are often designated as sustainable food production systems that are still facing various challenges, especially when they are considered as a commercial endeavour that needs to compete on the market. The early stages of the aquaponics industry have witnessed a number of unrealistic statements about the economic advantageousness of aquaponics. This chapter deals with these topics and discusses them critically. The latest scientific literature and current personal experiences of European commercial aquaponics farmers are taken into account on three levels: The horticulture side of production, the aquaculture side of production and the early data on the market response to aquaponics, emphasising the marketing issues and public acceptance of aquaponics. In summary, the chapter does not provide an “off-the-peg” solution to evaluate the economic performance of a particular aquaponics system. Instead it provides a broad database that enables an estimation of the efficiency of a planned system more realistically, pointing to challenges that the commercial aquaponics early adopters faced that are important lessons for future aquaponic endeavours, particularly in Europe.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction: Beyond Myths

Although we have witnessed the first research developments in aquaponics as far back as the late 1970s (Naegel 1977; Lewis et al. 1978), there is still a long road ahead for the sound economical assessment of aquaponics. The industry is developing slowly, and thus available data is often based on model cases from research and not on commercial-based systems. After initial positive conclusions about the economic potentials of aquaponics in research-based settings of the low-investment systems in USA, primarily the system in Virgin Islands (Bailey et al. 1997) and Alberta (Savidov and Brooks 2004), commercial aquaponics encountered a high level of early enthusiasm in business contexts, often based on unrealistic expectations.

To provide a specific example, in its early market forecast, IndustryARC (2012) anticipated that aquaponics as an industry has a potential market size of around $180 million in 2013 and is expected to reach $1 billion in sales in 2020. Later they projected aquaponics to increase from $409 million in 2015 to $906.9 million by 2021 (IndustryARC 2017). The same report (IndustryARC 2012) provided a number of yet untested claims about aquaponics, for example, about the economic superiority of aquaponics in terms of output, growth time and diversification possibilities in a commercial setting. We name such claims here as “aquaponics economic myths” that have been a typical part of the early internet-fuelled hype on commercial aquaponics.

Take a look at their statement: “Aquaponics uses 90% less land and water than agriculture but has the potential to generate 3 to 4 times more food than the latter also” (IndustryARC 2012). Comments such as these are extremely vague, since it is not clear what exactly aquaponics is being compared to when the authors are referring to “agriculture”. Although aquaponics does use less water than soil-based food production, since the water used in soil-based production can be lost in the soil, not being absorbed by plants compared to staying in a recirculation loop with aquaponics. The exact amount of water savings depends on the type of the system. Additionally, “3 to 4 times more food” seems highly exaggerated. Aquaponics can have yields comparable to hydroponics (e.g. Savidov and Brooks 2004; Graber and Junge, 2009). Yet the statement glosses over the fact that at least in coupled aquaponics so-called operational compromises need to be made in order to find a balance between optimum parameters for healthy plants and fish (see Chaps. 1 and 8 of this manuscript), which can lead to aquaponics having lower outputs compared to hydroponics.

Therefore, statements like the above lack a clear definition of the reference scenario and the reference unit of comparison. In an economic assessment, higher output levels can only be compared meaningfully if there is a clear reference to the input levels required to achieve this output. In the assessment of aquaponic systems, higher outputs per area might be achieved compared to conventional agriculture, yet aquaponic systems might require more energy, capital and work input. Only referring to land as an input factor assumes that other production factors are not scarce, which is hardly the case. Therefore, statements like the above neglect the “all other things being equal” principle in economic assessments. Vaclav Smil (2008) calculates and summarises energy expenditure of different agricultural activities, utilising energy as the common denominator, and this allows us to compare different agricultural methods with the aquaponic approach.

A similar myth is contained in the statement: “A major advantage pertaining to the aquaponics industry is that crop production time can be accelerated” (IndustryARC 2012). An acceleration of crop production necessarily depends on the amount of nutrients and water, oxygen and carbon dioxide in the surrounding atmosphere and light and temperature available to crops – factors that are not elements of aquaponics per se but can be added via greenhouse management practices, such as fertilisation and irrigation heating and artificial lights. These additional elements, however, increase both the costs of investment and the operational costs, often being too expensive to be economically viable (depending of course on the location, type of crops and especially the price of crops).

Another economically important advantage of aquaponics provided in the report was that “aquaponics is an adaptable process that allows for a diversification of income streams. Crops may be produced depending upon local market interest and the interest of the grower” (IndustryARC 2012). What statements like this gloss over is the fact that diversification of production always comes at a price. Crop diversification necessarily includes higher levels of knowledge and higher labour demands. The larger the variety of crops, the more difficult it is to meet optimum conditions for all the selected crops. Large-scale commercial production thus looks for constant parameters for a limited number of crops that need similar growth conditions, allowing for large outputs in order to penetrate distribution via large distribution partners such as supermarket chains, and allow for the same storage and potential processing equipment and processes. Such large-scale production is able to use economies of scale to reduce unit costs, a basic principle in economic assessment, which is not usually the case for aquaponics at smaller scales of production.

Finally, the most important statement provided in the report was that “the return of investment (ROI) for aquaponic systems ranges from 1 to 2 years depending on the farmer experience as well as the scale of farming” (IndustryARC 2012). Such statements need to be taken with extreme caution. The scarce data that is available on return on investments reports on a much longer time: According to Adler et al. (2000), it takes 7.5 years of return for an approximately $ 300.000 investment in the hypothetical scenario of a rainbow trout and lettuce system. Recently, Quagrainie et al. (2018) reported a similar period of 6.8 years for the payback of an investment in aquaponics if the products can only be sold at non-organic prices. Real data on the economics of aquaponics is extremely hard to come by, since the enterprises that have ventured into commercial aquaponics are reluctant to share their data. In cases where enterprises are performing well, they either do not share their data, since it is considered a business secret, or if they do share data, such data needs to be taken with caution since typically these companies have an interest in selling aquaponic equipment, engineering and consultancy. In addition, enterprises that have failed in achieving profitability prefer not to publicly share their failures.

These “myths” are continually circulating online amongst non-experienced aquaponic enthusiasts, fuelled by hope for both high returns and a path towards more sustainable future food production. So there is a need to go beyond the myths and look at individual enterprises and provide an in-depth analysis on the basic and the general economics of aquaponics.

Even if realistic data on aquaponics were available, it has to be considered that such analyses are based on single cases. As aquaponic systems are far from technically standardised production systems, the diversity with respect to marketing concepts is even higher. So, data on every single aquaponics system lacks generalisability and can be regarded only as a single case study. General statements are therefore not valid if the framework conditions and technical and marketing specificities are not made transparent.

Journalistic publications about aquaponics often follow a narrative that elaborates on the general challenges of global agriculture, such as shrinking agricultural areas, humus loss and desertification, and then elaborate on the advantages of aquaponic food production methods. Apart from the above-mentioned mistake that in fact controlled environment system (CES) production is compared with field production, no distinction between agriculture and horticulture is made. Whilst the term “agriculture” technically includes horticulture, agriculture in its more specific sense is the large-scale crop production on farmland. Horticulture is the cultivation of plants, usually excluding large-scale crop production on farmland, and is typically carried out in greenhouses. Following these definitions, the plant side of aquaponics is horticulture and not agriculture. Thus comparing yield and other productivity properties of aquaponics with agriculture is simply comparing apples to oranges.

To state this differently, the horticulture side of agriculture is only a very small part of it. Large-scale crop production in agriculture mostly encompasses so-called staple food production: Cereals like corn, barley and wheat, oilseed like rape and sunflower and starchy root vegetables like potatoes. The agricultural area of Germany covers 184.332 km2 (Destatis 2015). Of that only 2.290 km2 (1,3%) is used for horticulture. Of the horticultural area, 9.84 km2 (0,0053%) is protected and under glass. Absolute and relative figures for other countries surely differ, but the example clearly shows that the plant side of aquaponics will only be able to substitute and thereby enhance a small fraction of our food production. Staple foods can theoretically be produced in CES under glass using hydroculture as demonstrated in NASA research (Mackowiak et al. 1989) and could surely also be cultivated in aquaponic systems, but due to the high investment needed for such production, it does not make sense to think of aquaponics replacing the production of these crops under the current global economic and resource conditions.

2 Hypothetical Modelling, Small-Scale Case Studies and Surveys Amongst Farmers

Early research on commercial aquaponics focused on evaluation and the development of specific, mostly research institute-led case studies. These first results were highly positive and optimistic about the future of commercial aquaponics. Bailey et al. (1997) concluded that, at least in the case of Virgin Islands, aquaponic farms can be profitable. Savidov and Brooks (2004) reported that the yields of cucumbers and tomatoes calculated on an annual basis exceeded the average values for commercial greenhouse production based on conventional hydroponics technology in Alberta. Adler et al. (2000) performed an economic analysis of a 20-year expected scenario of producing lettuce and rainbow trout and argued that the integration of the fish and plant production systems produces economic costs savings over either system alone. They concluded that an approx. $300.000 investment would have a 7.5-year payback period.

Technologically based dynamic optimization models are commonly used to represent production engineering relationships in aquaponics systems (Karimanzira et al. 2016; Körner et al. 2017). It is noticeable that so far hardly any different scales are considered, and previous studies like Tokunaga et al. (2015) and Bosma et al. (2017) are limited to small-scale aquaponics for the local production of food or are performed on data from research facilities, such as University of Virgin Islands’ aquaponics systems (Bailey and Ferrarezi 2017). Furthermore, as Engle (2015) points out, the literature on the economics of aquaponics is sparse, with much of the early literature based primarily on model aquaponics. Without realistic farm data, such projections often are overly optimistic because they lack details on expenses beyond the obvious ones of fingerlings, feed and utilities and do not include the everyday risks involved in farming. In this research on the economics of aquaponics, production functions are only partially reproduced and questions of process-based optimization addressed only to some extent. Leyer and Hüttel (2017) demonstrated the potential for investment accounting as part of an initial analysis to capture various parameters of an aquaponics facility. Furthermore, Engle (2015) points to the difficulties of estimating annual costs to operate in aquaponics farms since many of these systems are quite new. She also points out that modelling is based on hypothetical situations and that more realistic farm data is needed, whereby the unexpected expenses are incurred daily, “from screens that clog, pumps that fail, or storms that cause damage”.

As aquaponics started to grow both as a do-it-yourself (DIY) activity (Love et al. 2014) and as an industry (Love et al. 2015), research on real commercial farm case studies emerged. Specific case studies of aquaponics production were performed on commercial attempts, for example, in Puerto Rico (Bunyaviroch 2013) and Hawaii (Tokunaga et al. 2015), including also the case study of a small-scale aquaponics social enterprise (Laidlaw 2013) (see Chap. 24).

With the continuous rise in the number of aquaponics growers, the first in-depth analyses of the state of the art of the industry emerged, focused primarily on the USA. These studies showed a less optimistic picture of the emerging industry. Love et al. (2015) performed an international survey amongst 257 participants, who in the last 12 months sold aquaponics-related food or non-food products and services. Only 37% of these participants could be named as solely commercial producers who gained their revenue from selling only fish or plants. Thirty-six percent of the respondents combined the sales of produce with aquaponics-related material or services: Sale of supplies and equipment, consulting fees for design or construction of aquaponics facilities and fees associated with workshops, classes, public speaking or agro-tourism. Finally, approximately one third (27%) were organisations that sold only aquaponics-related materials or services and no produce. The average aquaponics production site of 143 US-based producers was 0,01 ha. By comparing this to the overall hydroponic production in Florida (29,8 ha), Love et al. (2015) concluded that the size of aquaponics producers is significantly smaller than hydroponic production and is to a large extent still more of a hobby activity than successful commercial enterprises. In terms of water volume, the aquaponics farms reported comparable sizes as typical RAS aquaculture farms in the USA. Yet nearly a quarter of respondents (24%) did not harvest any fish in the last 12 months, and the estimated overall size of fish production was 86t of fish, which is less than 1% of the farmed tilapia industry in the USA.

According to the same study, aquaponics was the primary source of income for only 30% of respondents, and only 31% of respondents reported that their operation was profitable in the last 12 months. For example, the median respondent received only $1000 to $4999 in the last 12 months, and only 10% of respondents received more than $50,000 in the last 12 months. This led Love et al. (2015) to conclude that aquaponic farms were small-scale farms, which is comparable to agriculture in general, since farms with gross revenues of less than $ 50,000 made up approximately 75% of all farms in the USA and farms with less than $50,000 typically sold only around $7800 in local food sales – making it thus necessary to combine farming income with other sources of income. It is therefore not surprising that aquaponics, like small-scale farming, relies heavily on volunteer work. Typically, there were a large number of unpaid workers, family members and volunteers working on these small units, with an average of six unpaid workers per facility.

Similarly, Engle (2015) addresses the 2012 census where 71 aquaponics farms across the USA were reported which represented 2% of all aquaculture farms. Of these, only 11% had sales of $ 50,000 or more, compared to 60% of pond-based aquaculture operations that had sales of $ 50,000 or more. Additionally, Engle (2015) points out to the difficulties of obtaining data from these farms, for example, estimating annual costs to operate in aquaponics farms, since many of these systems are quite new.

In summary, from an economic point of view, there is a research gap in so far that there are no records and analysis available which include statements about economically viable systems. Further research is needed that would take into account (a) the production possibility curves (normative), (b) the combined analysis of fish and plants including feedback between both, (c) the economic efficiency in combination with optimising the business processes and feedback (simultaneous optimization production process and economic efficiency) and (d) the consideration of different scales (scale efficiency) against the background of the environmental sustainability of this agricultural system. In addition, there are no comprehensive and reliable data that combine key factors such as production volumes, factor entitlements and cost structures, scaling and sales strategies derived from existing real investments. Further profitability analyses should consider temporal aspects and risk whilst formulating normative benchmarks that in turn can serve as the basis for investment decisions.

3 Hypothetical Modelling Data from Europe

In Hawaii, Baker (2010) calculated the break-even price of aquaponics lettuce and tilapia production based on a hypothetical operation. The study estimates that the break-even price of lettuce is $3.30/kg and tilapia is $11.01/kg. Although his conclusion is that this break-even can potentially be economically viable for Hawaii, such break-even prices are much too high for most European contexts, especially when marketing through retailers and conventional distribution channels. In the Philippines, Bosma (2016) concluded that aquaponics can only be financially sustainable if the producers manage to secure high-end niche markets for fish and large markets for fresh organic vegetables.

Aquaponics on tropical islands (Virgin Islands and Hawaii) and warm, frost-free zones (Australia) contrasts highly to locations further away from the equator. The advantages in warm locations are the lower costs of heating and the seasonally even availability of daylight, thus allowing for potentially low-cost systems to economically survive. A frost-free location close to the equator with little to no seasonal differences makes it cheaper and easier to set up and operate a system year-round, which allows for semi-professional family business setups in those regions. Additionally, local production in these areas is valued higher since leafy green crops are either hard to store (e.g. Australia/heat) or difficult to transport to the customers (Islands) and generally have a much higher contribution margin than in locations such as Europe and Northern America.

Aquaponics can have several advantages in an urban context. Yet, advantages are only effective if the specific urban framework conditions are taken into account and if additional communication efforts are put in place. Peri-urban agroparks are presented by Smeets (2010) as a technically and economically viable solution for urban agriculture, offering synergy potential with existing industry through residual heat and suitable logistics as well as alternative inorganic and organic materials streams, for example, CO2, from cement production. Rooftop aquaponics utilises “empty” spaces in urban areas (Orsini et al. 2017). Rooftops are often assumed to be free of cost “because they are there”. Yet every space in the city is of high value. An owner of a building will always seek revenue for the space they offer, even the utilisation of vacant rooftops. A rooftop farm carries a high economic risk and changes may have to be made to the building (vents and logistics). Rooftops are also interesting for solar energy production with less risk to the operator (see also Chap. 12).

Whilst aquaponics is often explicitly touted as a production technology suitable for urban environments and even areas with contaminated soil, the real estate cost is often completely underestimated. For example, official real estate prices in Germany can be examined via the online tool BORISplus (2018), revealing a significant gap between inner city limit prices and agricultural land prices. For example, peri-urban real estate within city limits in Dortmund, Germany, is in the 280 €/m2–350 €/m2 range, whereas agricultural land outside of the city limits is in the 2 €/m2–6 €/m2 range. In addition to that German building codes grant the privilege to farmers to erect agricultural buildings outside of the city limits. This legal and financial situation renders agricultural land in proximity to economic zones attractive for larger-scale aquaponic farms, leading to the above-mentioned concept of agroparks.

The placement of aquaponic farms raises challenges with customer perception. Citizens who have been interviewed about their preference of different urban agriculture concepts for inner city public land use showed a preference for usage that keeps the space accessible for citizens as well as a low acceptance levels for agroparks (Specht et al. 2016). The research results on the acceptance of aquaponics revealed a larger variance than the other potential utilisations, suggesting a citizen ambivalence due to a lack of information on the production method. Additional communication efforts are required as aquaponics is a highly complex and new production system unknown to most people in society including urban populations.

The potentials and risks of aquaponics in an urban context become clear from the paragraph above. Distinct strategies and contingency plans have to be developed in an urban context when planning to implement an aquaponics production facility.

Most of the data currently collected on commercial farmers is focused on locations outside of Europe. A sound economic assessment of aquaponics facilities in European latitudes and climates is difficult, because on the one hand only very few commercial plants exist in Europe and on the other hand technical equipment, scale and business models are very different in other parts of the globe, where commercial aquaponics is more widespread (Bosma et al. 2017). Whilst Goddek et al. (2015) and Thorarinsdottir (2015) provide a very good overview of European commercial plants and their challenges, they present only a few economic parameters such as (targeted) consumer prices, statements on “potentially” achievable income or break-even prices for production. Since these are only valid under the specific conditions of the investigated facilities, only limited statements can be transferred to other locations, even within Europe.

Whilst there are some specific assessments of productivity (e.g. Medina et al. 2015, Petrea et al. 2016), full market potential analysis and well-founded cost-effectiveness assessments are not known at the present time. In addition, there are initial studies on technical dynamic models using the methodology system dynamics such as Goddek et al. (2016) and Körner and Holst (2017). This illustrates how essential the availability of comprehensive data is in order to conduct sound profitability analysis.

One of the very few hypothetical modelling cases created with data from within Europe is Morgenstern’s et al. (2017) model. They provided technical data from the pilot plant of the University of Applied Sciences of South Westphalia, which consisted of a commercial fish farm and a standard horticulture system. In this case, investment and full-cost calculations with comprehensive detailed technical data for systems in three different scales were modelled. Model calculations for operational costs for a start-up period of 6 years and investment costs as well as a simplified cost performance difference calculation have been conducted for three differently sized aquaponic farms rearing European catfish (Silurus glanis) and producing lettuce. The calculated sizes were derived from the pilot plant located at the University of Applied Sciences of South Westphalia and the aquaculture scale of the project partner. Modelled aquaculture sizes were 3 m3, 10 m3 and 300 m3. A couple of general assumptions and simplifications were made for the calculations, which illustrate the above-presented critiques on the limitations of hypothetical modelling:

-

(a)

Less than average production quality and production losses within the first 5 years have been considered. The profitability calculations are based on a matured and stable production process starting in year 6.

-

(b)

Constant hydroculture production. The complete nutrient stream from the process water was calculated to be consumed by the hydroculture production of lettuce, regardless of seasonal differences and regardless of nutrient availability from the aquaculture.

-

(c)

The hydroculture grow bed size has been calculated to be 60 m2, 200 m2 and 5.500 m2.

-

(d)

Heating demand for hydroculture and aquaculture has been approximated with a slightly modified methodology of KTBL (2009). The modelled location of the farm is Düsseldorf, Germany.

-

(e)

Energy costs per kWh have been approximated for production with a combined heat and power (CHP) system with 15 ct/kWh (electricity) and 5,5 ct/kWh (heat), respectively. For simplicity, a CHP system has not been modelled.

-

(f)

Direct marketing of the products was assumed. Fairly optimistic, but not overly optimistic, market prices have been calculated for the products. No extended marketing costs have been included in the calculation, since the marketing effort required to build a customer base and stable market have not been addressed in the project. Neglecting marketing costs assumes that market prices in direct marketing come at no costs and therefore constitute a major simplification of the calculation.

-

(g)

No costs related to the real estate required for the farm have been included in the calculations. The rationale for this simplification is the vastly different costs for space depending on location and project context.

-

(h)

Labour cost has been calculated at minimum wage, which is a strong assumption with regard to high levels of human capital required to run complex aquaponics systems.

-

(i)

Mortality losses of 5% in the aquaculture system are compensated by overstocking at the start of each production cycle.

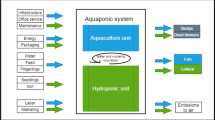

An analysis of the cost structure of the modelled production-sized aquaculture system shows that labour, fish feed and juveniles and energy are the main cost drivers, contributing roughly one third of the main costs each. At this point, it has to be emphasised that labour costs are calculated on a minimum wage basis and that costs for the occupied area of the farm have not been considered in the calculations (Fig. 18.1).

Cost structure for aquaculture side of an aquaponics system, hypothetical model from technical data from the pilot plant of the University of Applied Sciences of South Westphalia. (Based on Morgenstern et al. 2017)

Electricity and heating costs offer potential for optimization. Pumps have a lifetime between 2 and 5 years. Inefficient pumps can be replaced with more efficient pumps in the natural machine life cycle. Cost efficiency gains for these kinds of optimizations are simple to calculate, and efficiency gains are also easy to monitor after implementation. Similar measures to reduce heating costs are relatively easy to calculate. For example, the costs and effects of additional insulation panels can be calculated, and also here the gains can be easily monitored.

Labour costs emerge as the main cost driver that shows significant optimization potential with upscaling. Larger-scale systems allow for the usage of labour-saving devices, for example, automated graders or automated feeder-filling machinery. Profitability of these kinds of optimizations has to be calculated on a per-project basis.

Likewise, a cost analysis has been performed for the hydroculture part of the modelled systems. The main cost drivers are labour, seedlings and energy costs for lighting and heating. A higher operational maturity of the production, when the initial start-up learning curve has been mastered, can make room for in-house seedling production. The integration of this production step can offer cost optimization potential. Regarding cost reduction potential of the other cost drivers, energy and labour, the above-described situation is applicable for the hydroculture part as well (Fig. 18.2).

Cost structure for hydroponics side of an aquaponics system, hypothetical model from technical data from the pilot plant of the University of Applied Sciences of South Westphalia. (Based on Morgenstern et al. 2017)

A cost performance difference analysis has been performed for the three system sizes, showing that the microsystem and the small system are not economically viable. There is no exploitable automation and rationalisation potential because of the extremely small aquaculture sizes and the small hydroculture sizes resulting in prohibitively high labour costs. Minimum quantity surcharge and transportation fees for the fish feed and similar effects for other cost categories put an additional financial burden on these two systems.

The production size system has a positive cost performance difference when real estate costs or tenures for the required land are not taken into account (Table 18.1).

The analysis additionally sheds light on the job creation potential of the respective systems. The model calculation was performed under the assumption that all the required overhead tasks of the enterprise are handled by regular employees, an assumption that is rather optimistic with regard to the fact that the minimum wage has been used for the calculation.

One further assumption was made regarding the separation of jobs: The employees work on both parts of the sytem, the aquaculture and the hydroculture parts, in accordance to the work that is needed by the respective system. This requires an elevated skill set which puts another question mark behind the minimum wage calculation.

Even in the larger-sized production system, the number of jobs created is limited. The calculated number of jobs is congruent with experience from horticultural companies working with hydroponics, which usually employ between five and ten workers per hectare of greenhouse (Table 18.2).

Data on initial investments in aquaponics is on the one hand very difficult to come by and on the other hand even more difficult to compare. Some of the preliminary data collected from other sources on the initial investment needed to set up an aquaponics farm (see Table 18.3) below shows high differences between the initial investments in the systems, either real or in hypothetical modelling. Since the systems differ in the extreme amount of factors, it is highly problematic to draw any conclusions regarding the necessary initial investments. However, the initial investment in aquaponics does seem to be relatively high, which is reflective of the early stage of the industry. We estimate that an initial investment in a commercial aquaponics system in Europe starts with at least 250 EUR / m2 of growth area but can easily require a much higher investment, depending on the outside conditions, the system size and complexity and the length of the growth season aspired to (Table 18.3).

The experimental and pioneering status of commercial aquaponics is one reason why the financing of larger commercial-scale projects can be a challenge. Most aquaponic systems have been financed through research grants or through aquaponics enthusiasts. Personal communication with German banks that are traditionally strong in financing agricultural investments and that are therefore familiar with the intricacies of crop production and animal rearing revealed that they would not finance an aquaponics project due to lack of a proven and established business model (Morgenstern et al. 2017).

4 Aquaponic Farms in Europe

Thorarinsdottir (2015) identified ten pilot aquaponic units in Europe, approximately half of which were at the stage of setting up still rather small-scale systems for commercial production. Villarroel et al. (2016) estimated that the number of aquaponic commercial enterprises in Europe comprised approximately 20 companies. Currently, Villarroel (2017) identifies 52 research organisations (universities, vocational schools, research institutes) and 45 commercial enterprises in Europe. Only a handful of these, however, sell aquaponic produce and could be considered as an aquaponic farm. In 2016, as a spin-off from the COST FA1305 project, the Association of Commercial Aquaponics Companies (ACAC 2018) was founded, currently involving 25 companies from all over Europe, only about a third of which focuses on food production. Others offer mostly aquaponics-related services such as engineering and consulting (Thorarinsdottir 2015).

In the remainder of this chapter, we focus on the in-depth information from the few operating aquaponic systems in Europe. Within the time of the COST action (2014–2018), a number of organisations started and tested their first marketing attempts at commercial food production with the goal of making the sales of produce as their main income. We have gathered data with three in-depth qualitative methods: (a) site visits, (b) SME presentations at the COST FA 1305 conference (date, place) and (c) semi-structured in-depth interviews.

4.1 Site Visits

Within the COST FA1305 project, three European pilot aquaponic systems opened their doors for site visits of COST members:

-

Ponika, Slovenia, Matej Leskovec (site visit made on 23 March 2016).

-

UrbanFarmers AG, system in the Netherlands, Andreas Graber (site visit made on 6 September 2016).

-

Tilamur, Spain, Mariano Vidal (site visit made on 20 April 2017).

Within the site visits, we asked questions about the type and size of the system, the initial investment, the types of fish and crops produced and the reasoning behind it and the selling experiences.

4.2 Presentations

COST FA1305 organised a special conference devoted to presentations of aquaponics SMEs in Europe at the International Conference on Aquaponics SMEs at the University of Murcia (ES) (19 April 2017). We only analysed the presentations and answers to questions from SMEs that presented their experiences with their own commercial aquaponics system:

-

Bioaqua Farm, UK: Antonio Paladino.

-

NerBreen, Spain: Fernando Sustaeta.

-

Ponika, Slovenia: Maja Turnsek.

-

Samraekt Laugarmyri, Iceland: Ragnheidur Thorarinsdottir.

-

Tilamur, Spain, Mariano Vidal.

-

Uit Je Eigen Stad, Netherlands: Ivo Haenen.

4.3 Follow-Up In-Depth Interviews

We made additional follow-up semi-structured in-depth interviews with the aquaponics SMEs, contacting also other European aquaponic producers, some of which declined to participate.

The final interviewers were:

-

ECF, Germany: Christian Echternacht (interview made on 13 February 2018)

-

NerBreen, Spain: Fernando Sustaeta (interview made on 7 April 2018)

-

Ponika, Slovenia: Maja Turnsek (interview made on 30 January 2018)

-

Samraekt Laugarmyri, Iceland: Ragnheidur Thorarinsdottir (interview made on 19 February 18)

-

Uit Je Eigen Stad, Netherlands: Ivo Haenen (interview made on 8 February 2018)

The average interview lasted approx. 60 min. and included questions on the reasons for choosing aquaponics, type and size of the system, produce and fish type, experiences with growing, distribution and price, future plans and outlook for commercial aquaponics in the future. Below we will present the results together with the literature review on each of the areas of discussion (Table 18.4).

5 Horticulture Side of Commercial Aquaponics in Europe

Petrea et al. (2016) conducted a comparative cost-effective analysis on different aquaponics setups, utilising five different crops: baby leaf spinach, spinach, basil, mint and tarragon in deepwater culture and light expanded clay aggregate (LECA). Whilst the study was conducted in very small systems without taking into account any upscaling opportunity or potential, several aspects of the presented results are worth discussing. The grow beds have been illuminated in different lighting regimes with fluorescent bulbs and metal halide grow lights. The cost comparisons of the electricity illuminates the significant share plant lighting has on overall electricity cost. Furthermore, the analysis sheds light on the importance of sensible crop selection. Whilst tarragon is referenced as what is often called a “high-value crop” earlier in the text, the later economic crop yield analysis shows that other crops, basil and mint, generate a higher economic value per grow bed area (Petrea et al. 2016, p. 563).

The comparison shows a wide span of economic value ranging from 5.70€/m2/cycle (baby leaf spinach) up to 2110€/m2/cycle (basil) and 23.00€/m2/cycle (mint). Realistically, these figures should not be taken as reference points for upscaled commercial productions, but they illustrate how different the economic output of the crop production can be. Table 8 of the publication elaborates on the seasonal market price variability of the examined crops. The seasonal variations of these crops are rather moderate with slightly elevated prices in fall and winter months. Seasonal market price variations for produce and fruit with higher global market volumes like tomatoes and strawberries are usually much more pronounced, enticing producers to put effort into season extension at both ends. Artificial lighting for season extension is costly both investment-wise and regarding operational cost but might well be worthwhile, especially considering the inherent pressure to utilise process water from the aquaculture in the low light season.

No emphasis has been placed on product quality and marketability of the produced biomass within this study. Experience shows that the cultivation of certain crops is easier than the cultivation of others. Mint is generally regarded as an easy-to-grow crop, whilst the production of marketable basil is more challenging. Petrea et al. (2016) cultivated the crops in deepwater culture and ebb and flow grow beds with LECA substrate. The latter is particularly uncommon in commercial production, since it has close to zero potential for rationalisation and automation. Basil usually is produced in pot culture as opposed to a cut and come again production of mint which leaves the rootstock in the system with a faster regrowth of a marketable product. In addition to the different growth medium requirements, different crops are produced with differing temperatures, climate and light regimes. Optimal product quality can only be achieved with optimal cultivation techniques. It is important to remember that customers are used to premium quality and show little to zero tolerance for suboptimal products.

The horticulture side of commercial aquaponics faces high risks from infestations of diseases or parasites, which can be difficult to overcome because only biological controls can be used (see Chaps. 14 & 17). Large risks are involved also since most aquaponic farms require a market that will pay higher-than-average prices for the crop. Finally, aquaponics seems to be very labour-intensive since even small scale aquaponics systems are complex because of their many components and requirements (Engle 2015).

For start-ups, it might be tempting to strive for the production of a wide spectrum of novelty varieties of plant species with fruity aromas or colourful leaves. Melon sage (Salvia elegans) or pineapple mint (Mentha suaveolens ‘Variegata’) are examples for these kinds of varieties. According to small-scale commercial producers in Soest, Germany (non-aquaponics; personal communication summer 2016), the market demand for novelty varieties has long been recognised by retailers and is being supplied for by their large-scale producers. This segment is not a profitable niche any more but rather a market that follows yearly trends. The switch by the Berlin-based aquaponics producer ECF from a wide spectrum of the aforementioned plant species in their start-up phase to a basil monocrop that is being marketed through the German retailer REWE reflects this situation.

Christian Echternacht from ECF, Berlin, reported in the interview about the difficulty to sustainably establish a local direct marketing channel for a wider range of products of limited quantity. Drawing from their first-hand experience, the company decided to shift the plant-side production to one crop, basil in pots, and to market this crop via one single retailer in over 250 supermarkets in the city of Berlin. Interestingly the regionally labelled product (Hauptstadtbasilikum/Capital City Basil) without an organic label is placed directly next to organically labelled basil from non-regional sources and is reported to generate higher sales despite slightly higher prices.

NerBreen based in Spain with its 6000 m2 size is currently the largest system in Europe. It is more focused on the aquaculture element and includes aquaponics as one of several means of water filtration, but the plant production is still 3000 m2 and produces enough to create a market. They are currently undergoing the second season of production within the farm, having 5 years previous experiences with a smaller pilot plant (overall size of the pilot farm, 500 m2). In the winter season, they now grow fresh garlic, strawberry plants without fruit (since the plants need to be maintained for 3 years) and four different types of lettuce. In the summer, they replace the garlic with cherry tomatoes and peppers but keep the strawberries and the same lettuce varieties. Since this is only the second season, it is very difficult for them to provide an average amount of produce. The last winter was very cold, and it significantly affected the growth of the lettuce. In the first season, when they were still trying to improve and gain experience, they produced about 3t of strawberries, 5t of tomatoes and 60,000 lettuce heads. Their hopes are to ramp up production, whilst at the same time, their strategy shifted from putting a focus on the quantity to quality and variety instead. In the first year of their production, they had a good season with tomatoes in terms of quantity – but the overall market was flooded with tomatoes, and the price was subsequently too low. They adjusted to this problem with a focus on more selected, niche varieties of cherry tomatoes since the price is better, and they do not to want to compete with quantity but with quality, thus trying to reach a higher price with the retailers.

Locally produced crops and niche cultivars seem to be the main directions for crop selection in the European countries. The Slovenian company Ponika set out to sell fresh-cut herbs in their 400m2-sized system since providing niche products in the Slovenian market with no other local producer of fresh-cut herbs. The company based their rationale on three main reasons. The first was that the data available, albeit scarce, from US aquaponics farms showed that fresh-cut herbs seemed to be the crops that succeed well in aquaponics and gained a higher price in the market. The second was the years of positive experience within the small-scale DIY aquaponics garden with these crops. In addition, the third was the positive feedback received from fresh-cut herbs distributors in Slovenia regarding the interest in the crops. The company set out to produce fresh-cut herbs and managed to sell them to Slovenian gastro-distributors for two seasons, narrowing the initial number of crops from six to three: fresh-cut chives, basil and mint. Other fresh-cut herbs they tested proved to be either too sensitive, or there was too small and infrequent demand on the market. The plan was to first sell the fresh-cut herbs to the gastro-distributors and then gradually proceed to selling these to large-scale retail chains. The reality, however, showed significantly large risks in the production (e.g. powdery mildew with basil and yellow tips with chives) and too small a system to be able to secure a steady uninterrupted production as requested by the large-scale distribution chains. Although the margins would be higher, Ponika never started to sell to the retail chains since the contracts with large retail chains included financial penalties in the case where the farm could not deliver the orders. Additionally, the retail chains made weekly orders thus not allowing for appropriate planning, and in some cases, the excess that was not sold had to be collected by the farmer, and this discarded produce was expected to be deducted from the overall order even though the over-ordering was on the side of the retailer.

The main reasons for the Slovenian-based company Ponika to stop their operation were the combination of high risks accruing from the labour needed to cut, screen and package the produce combined with the average gained price of 8 EUR / kg of fresh-cut herbs (packaged in 100 g bundles) not providing enough of an economic return to cover the extra workload. Since the company was the only Slovenian company in the Slovenian market, the gastro-distributers were willing to take their produce over the imported produce – yet only if the prices were equal to what the prices of international competitors were on the market. With a high percentage of fresh-cut herbs sold in the European market being delivered from North Africa, the high extent of labour costs for aquaponically produced fresh-cut herbs meant that a small-scale system could not compete with the prices as set by the extensive fresh-cut herbs farms in warmer regions with lower labour costs, even when including transportation costs. This shows that even when there is a niche in a local market, there are often specific reasons for local producers not filling the niche. In the case of fresh-cut herbs in Slovenia, this was the high cost of labour for too small a niche market.

6 Aquaculture Side of Commercial Aquaponics in Europe

Starting a business in temperate climate regions of Europe or Northern America requires a larger investment since the systems have to be kept frost-free requiring more electrical energy for plant lighting when operated throughout the year. In Europe, there are two strong horticultural production powerhouses, one in Westland/NL and the other in Almeria, southern Spain. The market concentration is high and contribution margins are slim. As a result, some aquaponic producers presumed that in aquaponics the contribution margin from aquaculture is more interesting than that of horticulture, which is probably why some of the few commercial operators chose to oversize the aquaculture part of the setup. This can lead to technical issues because a larger quantity of nutrients than required by the plant side is being produced in the aquaculture side. The excess process water has to be discarded (Excursion Graber 2016 and Interview Echternacht 2018), putting the sustainability claims of aquaponics in question. Christian Echternacht from ECF reports that the contribution margin of the aquaculture has been overestimated in early calculations, rendering the oversizing of the aquaculture part of the farm counterproductive for the overall profitability of the farm.

Numerous different fish species have been reported to be produced in commercial aquaponics in Europe. Popular species for aquaponics production are tilapia, African catfish, largemouth bass, jade perch, carp and trout. There is no known commercial aquaponics farm currently rearing European catfish, but researchers at the University of Applied Sciences of South Westphalia (Morgenstern et al. 2017) found this species to be suitable for aquaponics production. The selection of fish species is influenced by a large number of different project-specific parameters. Most importantly of course are the market needs, price and distribution options. Within Europe, coastal regions have a traditionally strong market for marine fish with a diverse set of species and products. This creates a marketing challenge for freshwater aquaculture production. Ivo Haenen from Uit je Eigen Stad, Rotterdam, and Ragnheidur Thorarinsdottir from Samraekt Laugarmyri, Iceland, talked about this effect in their interviews. Rotterdam customers are used to a rich and diverse supply of marine fish products, making it difficult to market freshwater tilapia and African catfish. The marine wild catch tradition is so ingrained into Icelandic culture that the aquaculture aspect of aquaponics is probably not going to be actively promoted in future aquaponics projects.

Tilapia, one of the most commonly used fish species in aquaponics in the USA (Love et al. 2015), is a fish species that is not commonly known in Europe. As the experiences from NerBreen in Spain show, European tilapia aquaponics producers face a double marketing challenge: Their marketing attention needs to be put not only towards building customer awareness on the benefits of aquaponics production but also on the benefits of this relatively unknown fish species.

The suitability of the selected species for elevated water temperatures is another important factor. Fish are poikilothermic; thus their growth and consequently their production yields speed up with higher water temperatures. But elevated water temperatures require more energy, which, depending on the selected energy source for heating the process water, is connected with higher operational costs. Therefore, the positive effect of higher yields has to be balanced with the elevated costs for heating the water. From this perspective, it is desirable to tap into the potential of residual heat usage from adjacently located power plants or industries. These locations, however attractive and sensible they may be from an economical and ecological point of view, might pose a challenge for the overall marketing of the farm and its products. Industry sites are usually not idyllic and emotionally attractive, and worse still in case of anaerobic sewage plants or similar industries, they might even appear to be repulsive. Consequently, the available locations, and the context the farm can reasonably be placed in, is one factor for species selection.

The influence the different fish species have on plant yield and quality has not yet been completely researched. Knaus and Palm (2017) conducted experiments comparing plant yield in two identical aquaponics systems with identical operating parameters rearing tilapia and carp and found that plant performance with tilapia was better than with carp. These results show that there is indeed a difference in fish-plant interaction, but these have not been researched for a wider range of different species. In addition, the potential for fish polyculture, where two or more different fish species are reared in the same aquaculture cycle, has not yet been systematically researched.

One of the important operational factors for the fish selection is juvenile availability. Most of the commercial aquaponics producers buy juveniles from hatcheries. One notable exception is the company Aqua4C in Belgium that produces jade perch juveniles and uses these fish in their aquaponics system. A common recommendation is to select a species with at least two known suppliers with significantly larger capacity than the projected demand for the aquaponics farm. The rationale behind this recommendation is risk mitigation. If the supplier of juveniles experiences production issues and cannot deliver, the whole aquaponics production is in jeopardy.

As with the horticulture side of aquaponics, similarly the aquaculture part of aquaponics faces high technical risks, such as the death of the fish due to electricity outages, as reported by both Ponika from Slovenia and NerBreen in Spain. Ivo Haenen, former operator of the aquaponics system of the Urban Farm “Uit je Eigen Stad” in Rotterdam, reports that the heating system of the initial system setup was not dimensioned appropriately. An unexpected period of cold weather led to lower than tolerable process water temperatures resulting in losses in the aquaculture part of the operation. These kinds of instances have to be attributed to the pioneering character of early commercial aquaponics operations in Europe. The presented cases illustrate why Lohrberg and his team classified aquaponics in the “experimental” category of the seven identified business models of urban agriculture (Lohrberg et al. 2016).

7 Public Acceptance and Market Acceptance

The future of aquaponics production depends on public perception and the associated social acceptance in important stakeholder groups (Pakseresht et al. 2017). In addition to potential aquaponics plant operators, players at the wholesale and retail level as well as gastro-distributors and collective catering are important actors in supply chains. Moreover, consumers are key actors as they bring in the money into the supply chain at its end. Even though they have no direct economic stakes in aquaponics production, the general public as well as political and administrative bodies are important aspects to consider. The necessity of involving the aforementioned stakeholders is based on studies such as Vogt et al. (2016), who show that suitable framework conditions are an important basis for the establishment of innovative processes in food value chains. Technical developments without involving stakeholders run the risk of non-acceptance at the end of the research and development pipeline. In general, they build on a comprehensive understanding of a marketing philosophy with a multi-stakeholder approach.

For aquaponics, there is still no knowledge about the conditions that promote the dissemination of this technology. Although the technology used in aquaponics installations for freshwater fish farming in tanks is also used in aquaculture, until now this is unknown to a large part of society (Miličić et al. 2017). With regard to consuming plants from aquaponics, there is scepticism regarding their contact with fish water (Miličić et al. 2017). Preliminary studies based on a small sample regarding the acceptance of aquaponics products by potential consumers indicate that the requirements for products from aquaponics facilities go far beyond what the previous purchasing behaviour of fish products suggests (Schröter et al. 2017c). Based on the results of Schröter et al. (2017a), first hints on the effect of information on the acceptance process are available. These need to be further explored by means of perceptual and impact analyses of various information and presentation variants (e.g. textual facts, images, word-image content) and validation on the basis of representative samples. In addition, previous research has focused on citizens in general and on potential consumers. Studies on the acceptance of other important stakeholders such as potential plant operators, food retailers and public catering as well as political and regulatory actors and the general public are lacking completely.

First analyses of the consumers’ response on aquaponics indicate that consumers showed a positive attitude towards aquaponics, with food safety issues being the major consumer concern in Canada (Savidov and Brooks 2004). Initial preliminary work on the willingness to pay for fish products from aquaponics was carried out by Mergenthaler and Lorleberg (2016) in Germany and Schröter et al. (2017a, b) on the basis of non-representative samples in Germany. Part of these studies show a relatively high willingness to pay for fish products from aquaponics. However, these results are based on small samples and cannot be generalised because the willingness to pay has been compiled from a specialist target group (see Mergenthaler and Lorleberg 2016) or in connection with the visit to a greenhouse for tropical and subtropical plants grown using aquaponics (Schröter et al. 2017a, b).

According to Tamin et al. (2015), aquaponics products are green products. A product is defined as green when it includes significant improvements in relation to the environment compared to a conventional product in terms of the production process, consumption and disposal (Peattie 1992). Based on the “theory of planned behaviour (TPB)”, consumer acceptance of aquaponics products as innovative green products has been examined by Tamin et al. (2015) with closed-ended questionnaires in Malaysia. From a set of different behaviour-influencing factors (relative advantage, compatibility, subjective norm, perceived knowledge, self-efficacy and trust), two factors have been identified as having a significant impact: Relative advantage and perceived knowledge. The relative advantage describes how far buying behaviour is influenced by superior product qualities compared to conventional products. The aquaponics products were perceived fresh and healthy, and this perception led to a buying advantage. The perceived knowledge relates to how much the customer knows about the production method. The more the customers were familiar with the method, the more likely they were willing to buy aquaponics products. There was no correlation in the category subjective norm, which relates to how much the buying decision is influenced by the opinion of friends and family. Interestingly there was no correlation for the factor of compatibility. This factor relates to how much the product buying experience is compatible with the customer lifestyle. It seems as if the product to market process in Malaysia is not very different for aquaponics products and conventional products. So while it is questionable whether the results of this study can be safely transferred to European markets, a base message is that education about the production method and communicating the beneficial effects regarding the freshness of the food and the benefits for the environment are important marketing activities (Tamin et al. 2015).

Zugravu et al. (2016) surveyed the purchase of aquaponics products in Romania. Customers were influenced by friends and family. This dimension, subjective norm, showed no correlation in the Malaysian survey. The survey finds that consumers have a general good overall image of aquaponics. They think that the products are good for their health and that they are fresh. The paper describes a discrepancy between the perception of fish from aquaculture and wild catch and the perception of aquaculture. Retailers think that farmed fish can have a negative image, but actually aquaculture itself does not really have a pronounced image. The lack thereof is perceived by retailers as a marketing risk, yet it is described in the paper as giving the potential for positive branding through targeted communication. As a recommendation, the paper concludes that the retailers should build on the trust that the consumers showed when purchasing these fish products and should label the aquaculture fish as “healthy and fresh” (Zugravu et al. 2016).

Interestingly both Tamin and Zugravu had a significant higher questionnaire return count from women (Tamin et al. 2015; Zugravu et al. 2016). This raises the question about gender differences in aquaponics marketing. Although quantitative studies include gender as an independent variable in their analyses, no systematic and consistent patterns have been found yet. This asks for more research explicitly addressing gender aspects.

According to Echternacht from ECF in Germany, whose main business model is to set up aquaponics systems, marketing is the component that is usually most underestimated by their potential clients. ECF Farmsystems builds on this experience and surveys their potential customers for their intended marketing and distribution goals. If they have an existing business with actual production and established marketing channels, then the customer is very interesting. Idealistic customers who think that the products are going to market themselves are treated with caution.

Depending on the intended target group, different scales of production units might be favourable. Whilst some consumer segments prefer small-scale production possibly linked to short transportation distances and local production, there might be other consumer segments more interested in resource efficiency and low-cost production which can be realised in rather large-scale production units linked to waste energy and waste heat sources. Results from Rostock show (Palm et al. 2018) that small-scale systems with simple technology can make sense. Medium-scale systems require all the maintenance and the operational expenses of larger-scale systems, but do not have the benefit and output of large-scale systems. Conclusions from their experience show that you should either go small and achieve high prices in local markets or go to larger-scale systems with respective exploitation of economies of scale allowing for price reductions. Bioaqua from the UK is one of the rare European aquaponics companies that decided to follow the path of small-scale production with simpler and cheaper systems and providing the added value via catering and finding niche products for direct distribution to restaurants.

There might be other consumer segments displaying high preferences for fish welfare who therefore have to be targeted with fish from production units that conform to these ideals. As Miličić et al. (2017) show, consumers can express unexpected aversions, such as vegans expressing highly negative attitudes towards aquaponics. As pointed out in the literature, some facets of aquaponics may arouse high emotional involvement, such as the aesthetics of the aquaponics system (Pollard et al. 2017), level of mechanisation (Specht et al. 2016), soilless crop production (Specht und Sanyé-Mengual 2017), fish welfare (Korn et al. 2014), concerns about health risks due to the water recirculation system (Specht und Sanyé-Mengual 2017), or negative emotions bordering on disgust, because fish excrement is used as fertiliser for vegetables (Miličić et al. 2017). In this context, the perception and evaluation of aquaponics and its products may be based on unconscious processes rather than on careful consideration of logical arguments.

For some consumer segments, plants from aquaponics are innovative and interesting, and for others the link between fish and plant production might not be acceptable. This is also shown by ECF in Berlin: ECF decided to modify their initial production and marketing strategy. In the beginning, they attempted to produce a wide range of crops and market them directly on location. Nevertheless, according to Christian Echternacht (Interview Feb 2018) the marketing effort is simply too large. From their experience, the customers do not want to visit too many locations with only a few products at each location. Therefore, ECF decided to produce only one crop, basil, that is being marketed through a supermarket chain. Their experience as well as more comprehensive literature reviews shows that depending on the degree of meeting customer expectations, different levels of willingness to pay can be achieved and therefore achievable market prices are highly context specific.

Similarly, Slovenian-based company Ponika first attempted direct distribution of their fresh-cut herbs to restaurants in Ljubljana. But, just as with individual customers, restaurants were also averse to direct ordering even if the price was lower. For the restaurant managers, the time and effort needed to order individual products was much too high a price to pay, and they were not willing to order directly. They preferred to stay within their own gastro-distributors, whereby they could make their overall purchase in just one order.

The experiences of ECF from Berlin and Ponika from Slovenia described above are in line with previous experiences in the marketing of organic food products. To sell these products locally through direct distribution will only be possible for a small part of the products. Even though many consumers want to buy local and/or organic products, they often want to make their purchases as conveniently as possible. This means that shopping has to be efficient in order to fit into their daily schedule. As shown by Hjelmar (2011) for organic products, the availability of these food products is important for consumers because most of the consumers are pragmatic. They do not want to go to several stores in order to get what they want. They want to buy their products conveniently in a nearby supermarket and if the supermarket does not have a wide selection of organic products, many consumers end up by buying conventional products (Chryssohoidis and Krystallis 2005). Similar experiences can be described for consumers buying regional products in Germany (Schuetz et al. 2018). The same will presumably apply to aquaponics-grown products. If these products will not be available in supermarkets, aquaponics will probably remain niche production.

Organic food shoppers constitute a special potential target group of aquaponics. Indoor production of vegetables might require less or no pesticide applications, but soilless cultivation of plants is not an option in today’s legislation on organic agriculture (cf. Chap. 19 of this book). Therefore, aquaponics in its strictest sense will not provide the necessary characteristics to be eligible for certification as organic production and no organic labels would be allowed on aquaponics products. Therefore, either policymakers have to be lobbied to induce changes in organic legislation, or organic shoppers have to be educated in this rather complicated issue. This aspect is also important in the regard that organic classified products usually achieve higher market prices than conventional products, and such certification would make the aquaponics systems more economically viable. If aquaponics-grown products can be sold at the same prices as organic products, under certain conditions, the payback period of aquaponics systems can be reduced by less than half (Quagrainie et al. 2018).

Besides product marketing, services surrounding aquaponics production can generate additional income streams. The high level of innovativeness of aquaponics generates high levels of interest, which can be exploited in different service offers which included paid-for aquaponics visits, workshops and consultancy services around the establishment of new aquaponics systems. There are several examples of aquaponics facilities venturing in this direction:

-

ECF provides business consultancy for the establishment of new aquaponics systems.

-

UrbanFarmers, Den Hague, offered paid visits to the facility as well as an event location. (Note: The project has now ceased).

Besides adjusting production systems to customer expectations in a comprehensive marketing concept, communication strategies also play a role. Up to now, knowledge about aquaponics in the society is weak (Miličić et al. 2017; Pollard et al. 2017). When acquiring information, different variants of information and of information representation will significantly influence the public perception of this innovative technology. To satisfy the stakeholders’ information demands, different channels of communication and different information materials can be used. Diversification strategies are required that include workshops, visitor guides and other services. There are opportunities for new and alternative business ideas. Examples of innovative communication approaches by some commercial aquaponics operators show the specific challenges associated with aquaponics:

-

1.

ECF, Berlin: Choosing red variety of tilapia. Branding as “Rosébarsch” at the beginning of sales. Inspired by a customer’s branding in a restaurant, ECF rebranded to “Hauptstadtbarsch” (capital city perch) in the meantime (Interview Echternacht 2018). Thereby regional branding is put in the foreground of communication rather than the inherent product quality oriented at the colour of the fish meat.

-

2.

Aqua4C, Belgium: They introduced jade perch from Oceania into the European market. Aqua4C developed a branding as “Omega Baars” thus taking a novel food approach. They implicitly market the regionally unknown fish species as healthy while carefully avoiding to make any health claims.

-

3.

Ponika, Slovenia: Marketing of produce from aquaponics has been difficult. The situation was complicated as the aquaponics farm was located far away from the market which was too far for a quick visit and also no other attraction was nearby. They concluded that without the possibility of visits, it would be difficult to secure the farm additional revenue sources or marketing directly to consumers. In their marketing approach, they thus first targeted gastro-distributors with a focus on quality and local production for a competitive price. They did not dare to target individual consumers via supermarket chains due to having too small of a system and subsequent inability to secure a steady, large enough volumes of production. Thus they sold fresh-cut herbs directly to gastro-distributors, whereby the price and local production played the most important role. Their experience showed that gastro-distributors liked the story of innovative food production and they liked helping young people in their start-up business. So they were supportive in the sense that they adopted their purchasing process by taking up the produce when it was available and ordering from foreign sellers when it was not. In general, however, they were not very interested in the sustainability character of aquaponics – in other words, they did not care how the fresh-cut herbs were produced but rather that they were locally produced and had appealing packaging (1 kg and 1/2 kg) where the local character of the production was emphasised. Thus in their experience with retailers, a company story of young innovators worked the best. Customers at the retail level furthermore did not like the connection with hydroponics as they mixed aquaponics and hydroponics. In Slovenia, the customers are wary of hydroponics, and the Ponika company needed to tackle the challenge of changing the consumer’s perception from hydroponics, which has a negative image as being “unnatural”, into aquaponics and create a positive image of aquaponics. Additionally, the selection of fresh-cut herbs for the individual consumers proved to be problematic, since the health benefits were not important enough in fresh-cut herbs as people just do not eat that much of those to care enough about, for example, pesticide-free production.

-

4.

NerBreen, Spain: NerBreen is focused more on the aquaculture element of their business, since 70% of their business model represents the revenue from selling the fish. Yet they provide extensive marketing of both the fish and the vegetables. In both cases, they try to target the individual consumers via retail chains, preferably those retailers that target consumers who are willing to pay the premium price for higher local quality, aiming for approximately 20% higher prices than average. They face challenges in the marketing of both vegetables and tilapia. With vegetables they focused on fresh garlic and cherry tomatoes because they could reach higher prices due to smaller competition in those areas. Their marketing efforts include well-designed packaging with leaflets, whereby they explain the sustainability benefits of aquaponics. Here, they focus both on securing premium quality and adding additional story to their branding. When selling tilapia, they face a bigger challenge. The Spanish consumers currently have a negative perception of tilapia since they either mistake it with pangasius which is considered as a cheap and low-quality fish or they think it is imported from intensive aquaculture from the Far East and similarly ancd supposedly to be lower in quality. Within their marketing efforts, NerBreen thus needed to change this negative image and is focusing on providing information on the fact that this tilapia is locally produced, whereby both the water quality and the fish feed quality are of highest consideration, resulting in a high-quality fish product.

-

5.

Urban Farmers, Netherlands: In an effort to generate additional income streams, they established visits of aquaponics production facilities. It is, however, currently questionable if the visitor business is economically sustainable. Questions arise whether the visitor stream will wane when the hype around aquaponics settles or once “everyone” has already seen it. Apart from visitors, other income streams are already tapped: Rooftop Farms offer gardening workshops. (It should be noted that Urban Farmers in the Hague ceased to trade.)

Print media and social media are suitable for public education, as well as thematic workshops, guided farm visits and tastings of aquaponics products (Miličić et al. 2017). However, information provision will be successful only if it meets the information needs of the target audience. Stakeholders, such as representatives of national governments, different associations (e.g. organic farming associations), plant operators or plant manufacturers are probably more interested in comprehensive factual information. For citizens’ and consumers’ information, focusing on emotion and entertainment could be more attractive. With regard to this target audience, pictures combined with concise text messages are particularly suitable for information transfer. For these stakeholders beyond conscious information perception and information processing, also unconscious effects play an important role. Different frames, that mean different presentation formats of the same information, can influence the recipient’s behaviour in different ways (Levin et al. 1998). For a better understanding of the unconscious processes that may influence the stakeholders’ behaviour, neuroeconomic research methods in association with traditional methods of market research are useful tools. Eye tracking makes it possible to answer questions regarding visual perception in an objective way. Combined with other empirical methods of communication research, especially qualitative and quantitative surveys, it is possible to conduct complex perception and impact analyses. As a pilot study by Schröter and Mergenthaler (2018a, b) shows, attitudes towards different aquaponics systems are related to the gaze behaviour of the study participants whilst viewing information material about aquaponics.

This underlines the importance of a careful and target group-oriented design of information material about aquaponics. The possible solutions are that either production planning has to accommodate and to add the additional revenue sources or direct marketing by growing a large variety of different crops, thereby further complicating the production process. Yet as, for example, ECF in Germany shows, they started with a variety of vegetables but decided to focus only on basil and sell it through one large retail chain. Another possibility is to build strategic alliances with other regional producers in order to achieve innovative marketing and distribution strategies. In general, however, we can conclude that the marketing aspect of commercial aquaponics is one of its most important challenges and one in which European aquaponics farms had to undergo a number of changes in attempts to try and find the right product-market fit. It remains to be seen, however, whether this product-market fit has been found and how stable it will remain.

8 Conclusion and Outlook

As discussed in this chapter, economic evaluations of aquaponic systems are still a very complex and difficult task at present. Although aquaponics is sometimes presented as an economically superior method of food production, there is no evidence for such generalised statements. Up to now, there is hardly any reliable data available for a comprehensive economic evaluation of aquaponics. That is partly because there is not “one aquaponics system”, but there exist a variety of different systems operating in different locations under different conditions. For example, factors such as climatic conditions, which mainly affect the energy consumption of the systems, wage levels, workload required for operating the systems, and legal conditions have to be considered on the cost side. On the revenue side, factors such as the chosen fish-plant combination with its specific product prices, the option to manage the systems as organic production as well as the long-term public acceptance of the aquaponics systems and their products have an impact on the economic assessment. Not least, the economic evaluation of aquaponics in its strictest sense should be done in comparison to recirculating aquaculture systems and hydroponics systems as stand-alone systems.