Abstract

Foodborne illness outbreaks associated with contaminated fruits, vegetables, and salads have led to a reexamination of means to improve agricultural, postharvest, and supply chain controls. Irradiation is an effective means of inactivating human pathogens on a variety of fresh and fresh-cut fruits and vegetables. This chapter will describe and compare the technologies used to generate and apply irradiation. The literature on the efficacy of the process will be discussed and the commercial aspects of implementation will be examined, including issues related to packaging suitable for irradiation. Details will be presented on the regulations governing irradiation, both in the US and in major trading partners internationally. Finally, this chapter will summarize recent research related to this nonthermal processing technology as it can be applied to fresh produce for food safety purposes.

Similar content being viewed by others

Keywords

14.1 Introduction

In the US, per capita consumption of fresh produce is increasing, with fresh and fresh-cut fruits and vegetables among the fastest growing market segments (Calvin 2007; ERS 2008; CNPP 2010). However, as produce consumption has increased in the US, so have produce-related outbreaks. Responsible for only 0.7 % of all reported foodborne outbreaks in the 1970s, contaminated produce was the causative agent in 6 % of all outbreaks in the 1990s (FDA 2004; Sivapalasingam et al. 2004). The Centers for Disease Control and Prevention reported that foodborne outbreaks associated with fresh produce doubled between the period 1973–1987 and 1988–1992 (Buck et al. 2003; CDC 2011). The plant commodity group accounted for 66 % of viral, 32 % of bacterial, 25 % of chemical, and 30 % of parasitic illnesses from 1998 to 2008, with leafy greens being the single food most commonly associated with foodborne illness (Painter et al. 2013). From 1990 to 2005, produce accounted for 22 % of the most common outbreaks, 713 of total 3204 (CSPI 2007). Irrespective of the human cost of illness and death, medical costs and lost productivity due to foodborne illness has been estimated at $6.5–34.9B (IFT 2004). Scharff (2010) estimated that illnesses, produce recalls, and loss of consumer confidence cost approximately $39B annually.

Fresh and fresh-cut produce support the growth of commensal bacteria and bacterial human pathogens on their surfaces (Annous et al. 2005; Gómez-López et al. 2009). Salmonella spp., Escherichia coli O157:H7, Listeria monocytogenes, and Shigella spp. are regular contaminants of intact and minimally processed fruits and vegetables (Sivapalasingam et al. 2004; Mandrell 2009). In a recent comparison among antimicrobial sanitation methods, irradiation was identified as one of the most reliably effective interventions, surpassing chemical sanitizers and newly developed nonthermal methods (Goodburn and Wallace 2013). This chapter will present the scientific context and the latest research on irradiation as a method to inactivate human pathogens on fresh produce. The irradiation technologies available will be discussed, along with the relevant regulatory framework within which irradiation may be employed.

14.2 Irradiation Technologies

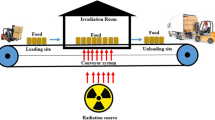

When irradiation is used as a food processing treatment, the dose is defined by the energy absorbed during exposure, measured in grays (Gy) . One gray represents one joule of energy absorbed per kilogram of irradiated product, the equivalent of 100 rad, or 0.1 Mrad. Food irradiation research typically reports doses in kilogray (kGy) . Energy absorbed depends on the product mass, bulk density, and thickness. An excessive dose may render the food unacceptable for consumption, while inadequate doses fail to achieve desired effects. The qualitative terminology used to describe doses are generally characterized as low (<3 kGy), medium (>3 and <10 kGy), or high (>10 kGy).

Commercial food processing uses e-beam (high energy electrons), X-rays, or gamma rays (high energy photons). An overview of the advantages and disadvantages of each is presented in Table 14.1. Each of the technologies induce ionization of molecules in the food target, leading to the generation of radicals, breakage of DNA, and other radiochemical effects. The irradiation equipment used in food irradiation is not energetic enough to induce radioactivity in the target. This process is discussed in greater detail below, under Sect. “General Mode of Action. Because of the ionization of the air within the treatment equipment, ozone and heat are generated during the irradiation process. For each of the technologies, proper ventilation and temperature control are key. This is especially important for the irradiation of fruits and other ozone-sensitive products. Failure to manage these secondary effects can potentially result in product degradation (Maxie and Abdel-Kader 1966).

14.2.1 Electron Beam

E-beams are produced by linear or cyclotron accelerators. These impart a high velocity, and therefore a high kinetic energy, to a stream of electrons. Commercial e-beam irradiators produce a focused beam of electrons with an energy of up to 10 MeV. The full processing dose is delivered quickly, taking typically <5 s. The electrons are aimed at the target, typically with a cone-shaped guide. As irradiation doses are additive in nature, higher doses may be delivered by repeated exposure. Short exposure time prevents any significant rise in temperature during processing.

The penetrability of the electron beam is lower than that of gamma rays or X-rays (Table 14.1); product must therefore be packaged accordingly. In commercial practice, many products are treated from multiple sides to enhance dose uniformity. A recent study by Moreira et al. (2012) demonstrated that the absorbed dose in a typical vegetable product (i.e., a tomato slice) can vary from 1.04 to 0.86 kGy over a distance of less than 4 cm. This nonuniformity is a function of the electron beam; material handling during irradiation is therefore crucial. Product can typically be stacked no thicker than 6–8 cm before absorption results in unacceptable dose distributions.

An advantage of e-beam irradiators over gamma irradiators is the electronic nature of the radiation source, which can be completely deactivated. As high-power, industrial scale electronic devices, electron accelerators require specialized training and maintenance for their operation, and the shielding required for an operating e-beam unit is comparable to that required for a gamma irradiator. Furthermore, the technical advantage of operation without radioisotopes is, to an extent, offset by the greater complexity of the electron accelerator.

14.2.2 X-ray

Familiar to the general public due to their widespread medical applications, X-rays are high-energy photons with much higher penetrability than the electrons of e-beams. Because photons will penetrate food products with very good uniformity, there is much less dose variation as compared with e-beam. Product can typically be stacked as thick as 30–40 cm without significant loss of penetration. The high-energy X-rays used in food irradiation require the same type of accelerator systems used in an e-beam irradiator. The beam of high-energy electrons is directed at a dense metal target. Electrons are absorbed by the metal atoms and the high-energy photons (X-rays) are emitted. The efficiency of this process is typically 5–10 %. Alloys of tungsten, tantalum, and various types of stainless steel have been used in the target plate; these vary in durability, cost, and efficiency.

The energy of the X-ray output depends on the energy of the originating e-beam and the conversion efficiency. Typically, 90–95 % of the energy that is directed at the metal plate is lost as heat; cooling subsystems function to stabilize operation and the temperature of the food processing chamber. Shielding for an X-ray irradiator is comparable to that required for the other two types of units. X-rays have a similar penetrability to gamma rays (Table 14.1) and can be used for bulk packages or higher density foodstuffs. Unlike gamma rays, X-rays are produced electronically. As they do not use radioisotopes, they can be completely inactivated in a power-off state. Some commercial irradiators can convert from e-beam to X-ray operation as needed by installation and removal of the metal target plate. While X-rays would seem to be an attractive middle ground between gamma and e-beam irradiators, the low energy efficiency, heat buildup in the metal plate and the low, but measurable, neutron scattering are drawbacks.

14.2.3 Gamma Ray

Gamma rays are high-energy photons produced by the disintegration of radioactive isotopes. These have the same excellent penetration as the photons of X-rays. In food irradiators, this is typically cobalt-60 and, less commonly, cesium-137. When cobalt-60 (half-life of 5.27 years) disintegrates into nickel-60 (a stable isotope), it emits two gamma rays of average energies of 1.17 and 1.33 MeV, respectively. Disintegration of cesium-137 (half-life of 30.17 years) to barium-137 produces gamma rays with energy of 0.66 MeV. Cobalt-60 has historically been the preferred radioisotope for food irradiation. Gamma rays from cobalt-60 are more energetic than those from cesium-137; higher dose rates mean shorter processing times. Also, cobalt-60 is the less expensive of the two isotopes. Finally, the CsCl form of cesium-137 in irradiators is water-soluble, a point of environmental concern. Cobalt-60 is a pure metal and is not water-soluble. It should be noted that these advantages of cobalt-60 are offset by its much shorter half-life. Cobalt-60 irradiators must be replenished with fresh radioisotope (“recharged”) much more frequently than cesium-137 irradiators. After 10.5 years of operation, a cobalt-60 irradiator will have approximately 25 % of its initial strength, while a cesium-137 irradiator will have retained approximately 80 % of its initial strength. A lower dose rate will lengthen treatment times.

Gamma rays have excellent penetrability, suitable for irradiating pallet- or crate-sized packages of product. The shielding required for a gamma irradiator is roughly comparable to that required for an e-beam or X-ray irradiator (Table 14.1). Gamma irradiators are more energy-efficient than e-beam or X-ray, as the photons are produced by radioactive decay, not electron acceleration. However, this also means that the source cannot be “turned off”; radioactive material must always be shielded, even during maintenance and downtimes. The time required for processing depends on the target dose and source strength. Longer processing times may prompt some form of temperature control for temperature-sensitive products such as fruits.

14.2.4 General Mode of Action

An e-beam interacts with the atoms directly, while high energy-photons (gamma rays or X-rays) energize electrons within the food target. These electrons may raise the energy of the electrons to a higher level within the atom (excitation) or leave the atom completely (ionization). Both processes yield free radicals, i.e., atoms with unpaired electrons on their outer shell. Free radicals are very reactive because their unpaired electrons readily pair with outer shell electrons of surrounding atoms within the food target. Water makes up the bulk of fresh fruits and vegetables; therefore, the majority of the absorbed irradiation energy hits water molecules, creating hydrogen and hydroxyl radicals (Diehl 1995). Interaction of these water-derived free radicals with the organic molecules that make up the food is the primary mode of action. Under conditions of limited free water, such as in dried or frozen products, this process is less efficient and fewer radicals are produced. Also, without free water, the radicals have reduced mobility and are more likely to recombine with each other than to interact with target microorganisms. In these products, higher doses become necessary for microbial control (Thayer and Boyd 1995; Nieto-Sandoval et al. 2000).

14.3 Food Safety Treatments

Low doses of irradiation effectively inactivate pathogens on produce (Fan et al. 2008; Gomes et al. 2008). In the US, regulations have long allowed for irradiation as a treatment to preserve freshness and control insect pests. Since 2008, processors have been permitted to irradiate spinach and iceberg lettuce to control human pathogens (FDA 2008). Commercialization has recently expanded with the establishment of an irradiation facility designed for treating leafy greens (Beach 2013).

14.3.1 Control of Human Pathogens

Radiation resistance of microorganisms is stated as D10 values, which are radiation doses (in kGy) required to inactivate 90 % of specific pathogens. Table 14.2 summarizes some of the typical D10 values obtained for three common foodborne pathogens (E. coli, Salmonella spp., and L. monocytogenes) on fresh and fresh-cut produce. The D10 values of the three pathogens range from 0.04 to 0.54 kGy. Radiation resistance of a pathogen can be influenced by many factors such as temperature and the gas atmosphere at which fresh-cut produce is irradiated, type of produce, strains of pathogens, and location of pathogen in/on fresh-cut produce.

For Salmonella-inoculated coriander, the efficacy of irradiation was maintained by cold storage. Reduced pathogen levels were seen on produce stored at 5 °C after irradiation, but storage at 22 °C led to pathogen regrowth after 2 days (Villagomez et al. 2010). During post-irradiation refrigerated storage, a 2-log reduction dose (0.42 kGy) led to regrowth of L. monocytogenes on endive, but no regrowth was seen after a 4-log equivalent dose (0.84 kGy) throughout the entire 19-days storage period (Niemira et al. 2003). Similarly, Romaine lettuce inoculated with L. monocytogenes gave D10 values of 0.16–0.25 kGy; the pathogen showed a persistent suppression during refrigerated storage after a 5-log dose (Mintier and Foley 2006).

E. coli O157: H7, L. monocytogenes, Salmonella enterica, and Shigella flexneri inoculated onto shredded Iceberg lettuce were significantly reduced by X-ray treatment (Mahmoud 2009). A 1-kGy dose gave reductions of 4.1–4.8 log10 cfu/g, while 2 kGy resulted in >5 log10 cfu/g reductions. The same four pathogens (E. coli O157: H7, L. monocytogenes, Salmonella enterica, and Shigella flexneri) were inoculated onto spinach leaves and irradiated (Mahmoud et al. 2009). Reductions obtained after 1 kGy ranged from 4 to 6 log10 cfu/g; a 2.0 kGy dose completely eliminated the contamination.

Incorporating irradiation into conventional produce processing is a key element in research. Interactions of human pathogens with produce surfaces, and the implications for dose optimization, are a subject of ongoing investigation. Post-irradiation re-growth of human pathogens can be influenced by when in the product handling chain the produce is irradiated.

As the response to irradiation is specific to individual commodities, specific handling practices, and combinations with other treatments, significant research gaps remain as to how best to use this technology.

14.3.2 Biofilm-Associated Pathogens

Time in storage prior to irradiation allows internalization of pathogens in stomata and biofilm formation on the surfaces of leaves (Niemira and Cooke 2010). Commensal bacteria and pathogens typically live as a biofilm, a complex community bound to inert and biological surfaces in a durable exopolysaccharide matrix (Korber et al. 1997; Fett 2000). Biofilms effectively reduce the efficacy of ozone, chlorine, hydrogen peroxide, and other antimicrobial processes, frequently by orders of magnitude (Stewart et al. 2004). Research suggests that although this attenuation is less dramatic for irradiation than for other antimicrobial processes, it remains a significant factor.

There is evidence that the irradiation response of biofilm-associated pathogens is dependent on strains and growth conditions. Biofilm-associated cells of Salmonella Stanley and Salmonella Enteritidis were significantly more sensitive than planktonic cells to irradiation (Niemira and Solomon 2005). In that study, the biofilm habitat did not change the radiation sensitivity of S. anatum. In a later study, biofilms of E. coli O157:H7 ATCC 43894 were grown at 37 °C for 24, 48, or 72 h. These biofilm-associated cells were significantly more sensitive to irradiation than respective planktonic cells (Niemira 2007a). E. coli O157:H7 ATCC 35150 biofilms were less sensitive to irradiation after 24 h of growth, but E. coli O157:H7 C9490 biofilms of the same age were more sensitive. Longer cultivation times (48 and 72 h) did not result in differential sensitivity for these isolates (Niemira 2007a). In that study, D10 values varied as much as 27 % above or below the D10 values obtained for planktonic cells. Temperature of biofilm cultivation engendered a complex response in L. monocytogenes and L. innocua. These biofilms were either equally sensitive or more sensitive to irradiation as compared with planktonic cells grown under the same conditions. (Niemira 2008).

Leaf-internalized E. coli O157:H7 cells had D10 values of 0.30–0.45 kGy, higher than those for surface-associated cells which had D10 of 0.12–0.14 kGy (Niemira 2007b). Biofilm-associated E. coli O157:H7 cells on the leaf surface were also less sensitive to irradiation (Niemira and Cooke 2010). While biofilm attenuation of chemical sanitizers is typically by orders of magnitude, irradiation was typically reduced in efficacy by ~50 %. Thus, the penetrating nature of ionizing radiation may make it uniquely suited to treating internalized, biofilm-associated, or otherwise protected pathogens on or in produce.

14.4 Phytosanitary Applications

14.4.1 Insect Pests and Import Controls

Irradiation inactivates insect pests on fruits and vegetables by: (1) sterilization (0.03–0.2 kGy) that prevents egg hatching and/or reproduction of the insects during or after storage; (2) killing insects outright (1–3 kGy). Irradiation is used as an alternative to fumigation, cold treatment, heat treatment, and other techniques. Given the environmental impact of chemical treatments, phytosanitary fumigation with ethylene dibromide and similar chemicals is increasingly restricted by legislation. Irradiation is an effective quarantine treatment for control of fruit flies and other insects in a number of commodities and is increasingly adopted worldwide. Australia and New Zealand recently approved the use of irradiation doses of up to 1 kGy to control insect pests on tomatoes and peppers (FSANZ 2013). The US Animal Plant Health Inspection Service has approved irradiation for protection against all insect pests including fruit flies, the mango seed weevil, and others. APHIS is currently seeking to facilitate the expansion of irradiation used in this way by streamlining the administrative oversight and data collection associated with its use (APHIS 2013).

14.5 Shelf-Life Extension

Irradiation with doses of 0.2–0.5 kGy can delay ripening of fruits by interference with biochemical processes (Dubery et al. 1984; Niemira et al. 2005). This extends shelf-life and marketability. A dose of 0.44 kGy reduced ethylene production as well as a variety of volatile esters and alcohols in Gala apples (Fan et al. 2001). That study used gamma rays, as the penetration of photons is appropriate for the density profiles of fruits and vegetables. The limited penetration of e-beam requires careful processing conditions to ensure dose uniformity; applications for changing ripening metabolism and increasing shelf-life has been demonstrated with fruits such as avocado (Grandison 1993). Climacteric fruits (i.e., fruits that show a transient increase in their rate of respiration and ethylene production at the onset of ripening) require irradiation before the onset of the climacteric increase in ethylene production (Maxie and Abdel-Kader 1966; Dubery et al. 1984). The necessity of treatment at an early stage of maturity can lead to abnormal ripening and uneven coloring; as in the case of tomato, an irradiation treatment applied too early may actually initiate a wound-response increase in ethylene production, accelerating ripening (Larrigaudiere et al. 1991).

The majority of tropical fruit s are climacteric, with a characteristically short shelf-life. These also tend to be sensitive to low temperature. Irradiation causes a shift from glycolysis toward the pentose phosphate shunt in bananas and toward the glyoxylate cycle in bananas and mangoes (Thomas 1986). Thus, irradiation interfered with the onset of senescence rather than delaying ripening of mango per se (Dubery et al. 1984). Respiration was enhanced in Gala apples treated with 1-methylcyclopropene, an ethylene action inhibitor (Fan and Mattheis 2001). Therefore, irradiation slows ripening in climacteric fruits by reducing (1) ethylene sensitivity and, (2) ethylene biosynthesis (Maxie and Abdel-Kader 1966; Larrigaudiere et al. 1991; Strydom et al. 1991). Irradiated Bartlett pears showed reducing ripening rates, even when subsequently exposed to ethylene (Bramlage and Couey 1965).

14.5.1 Sensory Impacts

In general, irradiation tends to cause hydrolysis of pectins and concomitant release of sugars following depolymerization of carbohydrate polymers (Amour et al. 1993; Yu et al. 1996). The delay of ripening notwithstanding, this pectinase-like action renders irradiated fruits softer and sweeter. Treated fruits are somewhat more susceptible to damage during handling and shipping. X-ray irradiation of 0.75 kGy reduced the firmness of papaya, rambutan, and Kau orange (Boylston et al. 2002). After 1.0 or 2.0 kGy, strawberries were softer, with increased water-soluble pectin and decreased oxalate-soluble pectin (Yu et al. 1996). In separate studies, irradiated strawberries and apples showed reduced titratable acidity and increased sweetness compared to unirradiated controls (Lovell and Flick 1966; Fan and Mattheis 2001). Grapefruit were able to tolerate 0.3 kGy with little loss of quality of the fruit, pulp, or juice if they were also treated with gibberellic acid (Miller and McDonald 1966). However, a higher dose of 0.6 kGy led to unacceptable levels of skin pitting, softening, and loss of juice quality.

In vegetables, overall sugar content is less than that for intact fruits. Fan et al. (2012) showed that irradiation (0.5 and 1.0 kGy) induced symptoms similar to russet spotting and other discolorations (pink ribs, rusty brown, and vein browning) in heads of Iceberg lettuce. This was true for both external and internal leaves. Neither pretreatment with 1 ppm 1-methylcyclopropene (an anti-browning agent) nor irradiation in the absence of oxygen had significant effect. The researchers determined that maintaining low oxygen atmosphere during the entire 14-day storage almost eliminated the disorders. Irradiation induced higher respiration, compared with non-treated control, as indicated by significantly lower headspace O2 and higher CO2 levels. The authors conclude that modified atmosphere packaging could mitigate irradiation-induced disorders in Iceberg lettuce.

14.6 Regulations

14.6.1 US and International

A joint FAO/IAEA/WHO study (1997) examined the wholesomeness of food irradiated above 10 kGy. In that study, it was concluded that food may be safely irradiated to any dose sufficient to achieve the desired physiological or microbial outcome, without appreciable loss of nutritional adequacy. Regulations governing commodities to be irradiated, the maximum (and in some cases, the minimum) dose to be applied, and the purposes for which a product may be irradiated are determined by individual countries. Approval and inspection of food irradiation plants are also nation-specific. However, international trade has trended toward increased harmonization of regulations in order to facilitate import and export.

The applicable regulations for food irradiation in the United States are presented in Table 14.3. Many European nations (e.g. Austria, Germany, Ireland) have approved only dry herbs, spices, and vegetable seasonings for irradiation, with a maximum dose of 10 kGy, a lower limit than that allowed for such food in the US (Table 14.3). A number of facilities have been licensed throughout the European Union for the purpose of irradiating herbs, spices, and seasonings, as well as onions and potatoes (for sprout suppression) (OJEU 2011). In the UK, commodities allowed to be irradiated include fruit (max. 2 kGy), vegetables (1 kGy), cereals (1 kGy), bulbs and tubers (0.2 kGy), dried aromatic herbs, spices, and vegetable seasonings (10 kGy), fish and shellfish (3 kGy), and poultry (7 kGy) (FSA 2012).

Chinese regulations encompass six general classes of food approved nationally for irradiation (Niemira and Gao 2011). These are (1) dried nuts and preserved fruits, (2) dried spices, (3) fresh fruits and vegetables, (4) frozen packaged meat of livestock and poultry, (5) beans, grains, and their products, and (6) cooked meat food of livestock and poultry. In addition to these general classes of food, three specific food items have been approved for irradiation: pollen, hog carcasses, and sweet potato wine. It can therefore be understood that regulatory approvals may be general or quite specific, based on the approach taken by the controlling legal authorities. As of 2009, the total amount of irradiated food in China is about 200,000 tons. Irradiation-induced extension of shelf-life serves to broaden the domestic market that Chinese manufacturers can economically reach.

In the United States, products which have been irradiated must be labeled with an indicative symbol called a “radura ” (Fig. 14.1). Regulations for labelling vary internationally, but product labelling must adhere to the regulations in effect in the point-of-sale nation, rather than those in effect for the county of origin.

14.6.2 Packaging

Like other food treated by irradiation, the use of this process with fruits involves constraints on the types of packaging materials available. Irradiation may affect the physical performance characteristics of packaging as well as undergo unwanted physical changes as a result of the irradiation itself. Traditional packaging materials such as metal, glass, and paper are relatively resistant to ionizing radiation. Although irradiation has minimal effects below 10 kGy, it is possible that volatiles may be generated from unsuitable plastics, producing unpleasant aromas or flavors. Irradiation acts on plastics primarily by cross-linking and/or cleavage of the polymers. The specific type of polymer used will determine the relative importance of each (Wilson 1974). Guidelines for the packaging materials permitted for irradiation in the United States are presented in Tables 14.4 and 14.5.

Plastics have historically been basic resin polymers, augmented with stabilizers, antistatic compounds, antislip agents, plasticizers, or other adjuvants. Plastic film laminates are increasingly used to provide the desired mixture of strength, durability, gas permeability, ability to take inks, etc. Each plastic component of the laminate has a unique response to irradiation including specialty laminates which may incorporate a metal foil barrier layer.

Active packaging, biodegradable plastics, and materials which release preservatives and antimicrobial compounds are an important area of innovation within packaging technology (Jin and Niemira 2011). These advanced materials can effectively suppress the growth of spoilage organisms or pathogens, enhance flavor, aroma, and color, or serve other important functions. The Codex General Standard for Irradiated Foods (Codex 1984) established general guidelines for packaging of irradiated food. For these materials to be used with irradiated food products to be sold in the US, the packaging materials compounds must be cleared by the U.S. Food and Drug Administration (Table 14.4). Some of these plastics may be amended with various adjuvants, including preservatives, etc. (Table 14.4).

14.7 Conclusions

Irradiation can effectively preserve and improve the safety, sensory properties, and shelf-life of a wide variety of fresh and fresh-cut produce. Preparation methods, storage protocols, shipment and transshipment conditions, and market forces will be key influencing factors in the application of this technology. Used singly or in combination with other treatments, irradiation is a processing intervention that can help domestic and international fresh and fresh-cut produce growers and suppliers provide consumers with the safest, highest quality produce possible.

References

Amour, J., C. Gosselin, J. Arul, F. Castaigne, and C. Willemot. 1993. Gamma-radiation affects cell wall composition of strawberries. Journal of Food Science 58: 182–185.

Annous, B.A., E.B. Solomon, P.H. Cooke, and A. Burke. 2005. Biofilm formation by Salmonella spp. on cantaloupe melons. Journal of Food Safety 25: 276–287.

APHIS (Animal Plant Health Inspection Service). 2013. Notice of request for extension of approval of an information collection; irradiation phytosanitary treatment of imported fruits and vegetables, http://www.gpo.gov/fdsys/pkg/FR-2012-10-31/html/2012-26727.htm (accessed Feb 22, 2103).

Bari, M.L., M.I. Al-Haq, T. Kawasaki, et al. 2004. Irradiation to kill Escherichia coli O157:H7 and Salmonella on ready-to-eat radish and mung bean sprouts. Journal of Food Protection 67: 2263–2268.

Bari, M.L., M. Nakauma, S. Todoriki, et al. 2005. Effectiveness of irradiation treatments in inactivating Listeria monocytogenes on fresh vegetables at refrigeration temperature. Journal of Food Protection 68(2): 318–323.

Beach, C. 2013. Canadian firm prepares to irradiate leafy greens. The Packer, p. B4. Jan 21, 2013.

Boylston, T.D., C.A. Reitmeier, J.H. Moy, G.A. Mosher, and L. Taladriz. 2002. Sensory quality and nutrient composition of three Hawaiian fruits treated by x-irradiation. Journal of Food Quality 25: 419–433.

Bramlage, W.J., and H.M. Couey. 1965. Gamma radiation of fruits to extend market life Marketing Res Rep No 717. Washington, DC: ARS-USDA.

Buck, J.W., R.R. Walcott, and L.R. Beuchat. 2003. Recent trends in microbiological safety of fruits and vegetables. Online. Plant Health Progress. doi:10.1094/PHP-2003-0121-01-RV.

Caillet, S., M. Millette, M. Turgis, S. Salmieri, and M. Lacroix. 2006. Influence of antimicrobial compounds and modified atmosphere packaging on radiation sensitivity of Listeria monocytogenes present in ready-to-use carrots (Daucus carota). Journal of Food Protection 69: 221–227.

Calvin, L. 2007. Outbreak linked to spinach forces reassessment of food safety practices. Amber Waves, USDA Economic Research Service, http://ideas.repec.org/a/ags/uersaw/125239.html (accessed Feb 26, 2103).

CDC (Centers for Disease Control and Prevention). 2011. CDC estimates of foodborne illness in the united states, http://www.cdc.gov/foodborneburden/PDFs/FACTSHEET_A_FINDINGS_updated4-13.pdf (accessed Feb 26, 2013).

Codex Alimentarius Commission. 1984. Codex general standard for irradiated foods and recommended international code of practice for operation of radiation facilities used for the treatment of foods, vol. XV. Geneva, Switzerland: WHO.

CNPP (Center for Nutrition Policy and Promotion). 2010. U.S. Dept. Agriculture—Dietary Guidelines for Americans, http://www.cnpp.usda.gov/dietaryguidelines.htm (accessed Feb 26, 2013).

CSPI (Center for Science in the Public Interest). 2007. Outbreak alert: Closing the gaps in our federal food-safety net, http://www.cspinet.org/foodsafety/outbreak_alert.pdf (accessed Feb 26, 2013).

Dhokane, V.S., S. Hajare, R. Shashidhar, A. Sharma, and J.R. Bandekar. 2006. Radiation processing to ensure safety of minimally processed carrot (Daucus carota) and cucumber (Cucumis sativus): Optimization of dose for the elimination of Salmonella Typhimurium and Listeria monocytogenes. Journal of Food Protection 69(2): 444–448.

Diehl, J.F. 1995. Safety of irradiated foods, 2nd ed. New York: Marcel Dekker.

Dubery, I.A., L.J. van Rensburg, and J.C. Schabort. 1984. Malic enzyme activity and related biochemical aspects during ripening of irradiated mango fruit. Phytochemistry 23: 1383–1386.

ERS (Economic Research Service), USDA. 2008. Food availability (per capita) data system, http://www.ers.usda.gov/Data/FoodConsumption (accessed Feb 26, 2013)

FAO/IAEA/WHO. 1997. High-dose irradiation: Wholesomeness of food irradiated with doses above 10 kGy, in joint FAO/IAEA/WHO study group on high-dose irradiation. WHO Technical Report Series 890.

Fan, X., and J.P. Mattheis. 2001. 1-Methylcyclopropene and storage temperature influence responses of Gala apple fruit to gamma irradiation. Postharvest Biology and Technology 23: 143–151.

Fan, X., L. Argenta, and J. Mattheis. 2001. Impacts of ionizing radiation on volatile production by ripening Gala apple fruit. Journal of Agricultural and Food Chemistry 49: 254–262.

Fan, X. 2005. Antioxidant capacity of fresh-cut vegetables exposed to ionizing radiation. Journal of the Science of Food and Agriculture 85: 995–1000.

Fan, X., B.A. Niemira, and A. Prakash. 2008. Irradiation of fresh and fresh-cut fruits and vegetables. Food Technology 3: 36–43.

Fan, X., K. Sokorai, B.A. Niemira, R.S. Mills, and M.Y. Zhen. 2012. Quality of gamma ray-irradiated iceberg lettuce and treatments to minimize irradiation-induced disorders. Hortscience 47: 1108–1112.

FDA (U.S. Food and Drug Administration). 2004. Produce safety from production to consumption: 2004 action plan to minimize foodborne illness associated with fresh produce consumption, http://www.fda.gov/Food/FoodSafety/Product-SpecificInformation/FruitsVegetablesJuices/FDAProduceSafetyActivities/ProduceSafetyActionPlan/ucm129487.htm (accessed Feb 26, 2013).

———. 2008. Final Rule (73 FR 49593), Irradiation in the production, processing and handling of food. 21 CFR Part 179, http://www.fda.gov/ForConsumers/ConsumerUpdates/ucm093651.htm (accessed Feb 26, 2013).

Fett, W.F. 2000. Naturally occurring biofilms on alfalfa and other types of sprouts. Journal of Food Protection 63(5): 625–632.

Foley, D.M., A. Dufour, L. Rodriguez, F. Caporaso, and A. Prakash. 2002. Reduction of Escherichia coli 0157:H7 in shredded Iceberg lettuce by chlorination and gamma irradiation. Radiation Physics and Chemistry 63: 391–396.

Foley, D.M., M. Euper, F. Caporaso, and A. Prakash. 2004. Irradiation and chlorination effectively reduces Escherichia coli O157:H7 inoculated on cilantro (Coriandrum sativum) without negatively affecting quality. Journal of Food Protection 67(10): 2092–2098.

FSANZ (Food Standards Australia and New Zealand). 2013. Application A1069—Irradiation of Tomatoes & Capsicums, http://www.foodstandards.gov.au/foodstandards/applications/applicationa1069irra5511.cfm (accessed Feb 22, 2013).

FSA (Food Standards Agency). 2012. Irradiated food, http://www.food.gov.uk/policy-advice/irradfoodqa/#.USfLRvLBmM0 (accessed Feb 22, 2013)

Gomes, C.R., G. Moreira, M.E. Castell-Perez, et al. 2008. E-Beam irradiation of bagged, ready-to-eat spinach leaves (Spinacea oleracea): An engineering approach. Journal of Food Science 73: E95–E102.

Gómez-López, V.M., A. Rajkovic, P. Ragaert, N. Smigic, and F. Devlieghere. 2009. Chlorine dioxide for minimally processed produce preservation: A review. Trends in Food Science & Technology 20(1): 17–26.

Goodburn, C., and C.A. Wallace. 2013. The microbiological efficacy of decontamination methodologies for fresh produce: A review. Food Control 32(2): 418–427.

Goularte, L., C.G. Martins, I.C. Morales-Aizpurua, et al. 2004. Combination of minimal processing and irradiation to improve the microbiological safety of lettuce (Lactuca sativa L.). Radiation Physics and Chemistry 71: 155–159.

Grandison, A.S. 1993. Combination treatments including electron beam irradiation for extending the shelf-life of fresh fruits. Communication at the 2nd FAO/IAEA Coordination Meeting on Irradiation in Combination with Other Processes for Improving Food Quality. FRDC, Saint-Hyacinthe, Quebec.

Hsu, W.Y., A. Simonne, P. Jitareerat, and M.R. Marshall Jr. 2010. Low-dose irradiation improves microbial quality and shelf life of fresh mint (Mentha piperita L.) without compromising visual quality. Journal of Food Science 75: M222–M230.

Jeong, S., B.P. Marks, E.T. Ryser, and S.R. Moosekian. 2010. Inactivation of Escherichia coli O157:H7 on lettuce, using low-energy X-ray irradiation. Journal of Food Protection 73: 547–551.

Jin, T., and B.A. Niemira. 2011. Application of antimicrobial polylactic acid coating in reduction of Escherichia coli O157:H7 and Salmonella Stanley on apples. Journal of Food Science 76(3): M184–M188.

Kamat, A.S., N. Ghadge, M.S. Ramamurthy, and M.D. Alur. 2005. Effect of low-dose irradiation on shelf life and microbiological safety of sliced carrot. Journal of the Science of Food and Agriculture 85(13): 2213–2219.

Khattak, A.B., N. Bibi, M.A. Chaudry, et al. 2005. Shelf life extension of minimally processed cabbage and cucumber through gamma irradiation. Journal of Food Protection 69(11): 2648–2663.

Kim, J., J. Lee, J. Kim, et al. 2006. Effect of gamma irradiation on Listeria ivanovii inoculated to Iceberg lettuce stored at cold temperature. Food Control 17: 397–401.

Korber, D.R., A. Choi, G.M. Wolfaardt, S.C. Ingham, and D.E. Caldwell. 1997. Substratum topography influences susceptibility of Salmonella enteritidis biofilms to trisodium phosphate. Applied and Environmental Microbiology 63: 3352–3358.

Larrigaudiere, C., A. Latche, J.C. Pech, and C. Triantaphylides. 1991. Relationship between stress ethylene production induced by gamma irradiation and ripening of cherry tomatoes. Journal of the American Society for Horticultural Science 116: 1000–1003.

Lee, N.Y., C. Jo, D.H. Shin, W.G. Kim, and M.W. Byun. 2006. Effect of gamma-irradiation on pathogens inoculated into ready-to-use vegetables. Food Microbiology 23(7): 649–656.

López, L., S. Avendaño, J. Romero, S. Garrido, J. Espinoza, and M. Vargas. 2005. Effect of gamma irradiation on the microbiological quality of minimally processed vegetables. Archivos Latinoamericanos de Nutrición 55(3): 287–292.

Lovell, R.T., and G.J. Flick. 1966. Irradiation of Gulf Coast area strawberries. Food Technology 29: 99–102.

Mahmoud, B.S.M. 2009. Effects of X-ray radiation on Escherichia coli O157:H7, Listeria monocytogenes, Salmonella enterica and Shigella flexneri inoculated on shredded iceberg lettuce. Food Microbiology 27(1): 109–114.

Mahmoud, B.S.M., G. Bachman, and R.H. Linton. 2009. Inactivation of Escherichia coli O157:H7, Listeria monocytogenes, Salmonella enterica and Shigella flexneri on spinach leaves by X-ray. Food Microbiology 27(1): 24–28.

Mandrell, R.E. 2009. Enteric human pathogens associated with fresh produce: Sources, transport and ecology. In Microbial Safety of Fresh Produce, ed. X. Fan, B.A. Niemira, C.J. Doona, F.E. Feeherry, and R.B. Gravani, 5–41. Ames, IA: Blackwell.

Maxie, E.C., and A.S. Abdel-Kader. 1966. Food irradiation-physiology of fruits as related to the feasibility of the technology. Advances in Food Research 15: 105–145.

Miller, W.R., and R.E. McDonald. 1966. Postharvest quality of GA-treated Florida grapefruit after gamma irradiation with TBZ and storage. Postharvest Biology and Technology 7: 253–260.

Mintier, A.M., and D.M. Foley. 2006. Electron beam and gamma irradiation effectively reduce Listeria monocytogenes populations on chopped romaine lettuce. Journal of Food Protection 9(3): 570–574.

Moreira, R.G., A.F. Puerta-Gomez, J.S. Kim, and M.E. Castell-Perez. 2012. Factors affecting radiation D-values (D10) of an Escherichia coli cocktail and Salmonella Typhimurium inoculated in fresh produce. Journal of Food Science 77: E104–E111.

Neal, J.A., E. Cabrera-Diaz, M. Márquez-Gonzaález, J.E. Maxim, and A. Castillo. 2008. Reduction of Escherichia coli O157:H7 and Salmonella on baby spinach, using electron beam radiation. Journal of Food Protection 71: 2415–2420.

Niemira, B.A., C.H. Sommers, and X. Fan. 2002. Suspending lettuce type influences recoverability and radiation sensitivity of Escherichia coli O157:H7. Journal of Food Protection 65(9): 1388–1393.

Niemira, B.A. 2003. Radiation sensitivity and recoverability of Listeria monocytogenes and Salmonella on 4 lettuce types. Journal of Food Science 68(9): 2784–2787.

Niemira, B.A., X. Fan, K.J.B. Sokorai, and C.H. Sommers. 2003. Ionizing radiation sensitivity of Listeria monocytogenes and L. innocua inoculated on endive (Cichorium endiva). Journal of Food Protection 66: 993–998.

Niemira, B.A., and E.B. Solomon. 2005. Sensitivity of planktonic and biofilm-associated Salmonella to ionizing radiation. Applied and Environmental Microbiology 71(5): 2732–2736.

Niemira, B.A., C.H. Sommers, and D. Ukuku. 2005. Mechanisms of microbial spoilage of fruits and vegetables. In Produce Degradation: Reaction Pathways and their Prevention, ed. O. Lamikanra, S.H. Imam, and D.O. Ukuku, 463–482. New York, NY: Taylor & Francis.

Niemira, B.A. 2007a. Irradiation sensitivity of planktonic and biofilm-associated Escherichia coli O157:H7 isolates is influenced by culture conditions. Applied and Environmental Microbiology 73(10): 3239–3244.

———. 2007b. Relative efficacy of sodium hypochlorite wash vs. irradiation to inactivate Escherichia coli o157:h7 internalized in leaves of romaine lettuce and baby spinach. Journal of Food Protection 70(11): 2526–2532.

———. 2008. Influence of growth temperature on irradiation sensitivity of planktonic and biofilm-associated Listeria monocytogenes and L. innocua. Food and Bioprocess Technology. doi:10.1007/s11947-008-0079-5.

Niemira, B.A., and P. Cooke. 2010. Escherichia coli O157:H7 biofilm formation on lettuce and spinach leaf surfaces reduces efficacy of irradiation and sodium hypochlorite washes. Journal of Food Science 75(5): M270–M277.

Niemira, B.A., and M. Gao. 2011. Irradiation as a non-thermal process for beverages, juices and fluid foods (Ch. 7). In Novel thermal and non-thermal technologies for fluid foods, ed. P.J. Cullen, B. Tiwari, and V. Valdramidis. Amsterdam, Netherlands: Elsevier.

Niemira, B.A., and X. Fan. 2013. Advances in processing technologies to preserve and enhance the safety of fresh and fresh-cut fruits and vegetables, Encyclopedia of food microbiology, 2nd ed. Ames, IA: Wiley-Blackwell.

Nieto-Sandoval, J.M., L. Almela, J.A. Fernandez-Lopez, and J.A. Muñoz. 2000. Effect of electron beam irradiation on color and microbial burden of red paprika. Journal of Food Protection 63: 633–637.

OJEU (Official Journal of the European Union). 2011. List of approved facilities for the treatment of foods and food ingredients with ionising radiation in the Member States, http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:C:2011:077:0014:0017:EN:PDF (accessed Feb 22, 2013).

Painter, J.A., R.M. Hoekstra, T. Ayers, R.V. Tauxe, C.R. Braden, F.J. Angulo, et al. 2013. Attribution of foodborne illnesses, hospitalizations, and deaths to food commodities by using outbreak data, United States, 1998–2008. Emerging Infectious Disease, http://dx.doi.org/10.3201/eid1903.111866 (accessed Feb 26, 2013).

Prakash, A., P. Inthajak, H. Huibregtse, F. Caporaso, and D.M. Foley. 2000. Effects of low-dose gamma irradiation and conventional treatments on shelf life and quality characteristics of diced celery. Journal of Food Science 65: 1070–1075.

Prakash, A., N. Johnson, and D. Foley. 2007. Irradiation D values of Salmonella spp. in diced tomatoes dipped in 1% calcium chloride. Foodborne Pathogens and Disease 4: 84–88.

Rajkowski, K.T., and D.W. Thayer. 2000. Reduction of Salmonella spp. and strains of Escherichia coli O157:H7 by gamma radiation of inoculated sprouts. Journal of Food Protection 63: 871–875.

Scharff, R.L. 2010. Health-related costs from foodborne illness in the United States. Produce Safety Project at Georgetown University, http://www.producesafetyproject.org/admin/assets/files/Health-Related-Foodborne-Illness-Costs-Report.pdf-1.pdf (accessed Feb 26, 2013).

Schmidt, H.M., M.P. Palekar, J.E. Maxim, and A. Castillo. 2006. Improving the microbiological quality and safety of fresh-cut tomatoes by low-dose electron beam irradiation. Journal of Food Protection 69: 575–581.

Shashidhar, R., V.S. Dhokane, S.N. Hajare, A. Sharma, and J.R. Bandekar. 2007. Effectiveness of radiation processing for elimination of Salmonella Typhimurium from minimally processed pineapple (Ananas comosus Merr.). Journal of Food Science 72: M98–M101.

Sivapalasingam, S., C.R. Friedman, L. Cohen, and R.V. Tauxe. 2004. Fresh produce: A growing cause of outbreaks of foodborne illness in the United States, 1973 through 1997. Journal of Food Protection 67: 2342–2353.

Stewart, P.S., P.K. Mukherjee, and M.A. Ghannoum. 2004. Biofilm antimicrobial resistance. In Microbial biofilms, ed. M.A. Ghannoum and G.A. O’Toole, 250–268. Washington, DC: ASM Press.

Strydom, G.J., J. Van Staden, and M.T. Smith. 1991. The effect of gamma radiation on the ultrastructure of the peel of banana fruits. Environmental and Experimental Botany 31: 43–49.

Thayer, D.W., and G. Boyd. 1995. Radiation sensitivity of Listeria monocytogenes on beef as affected by temperature. Journal of Food Science 60: 237–240.

Thomas, P. 1986. Radiation preservation of foods of plant origin. III. Tropical fruits: Bananas, mangoes, and papayas. CRC Critical Reviews in Food Science and Nutrition 23: 147–205.

Villagomez, N.S., E.A.N. Herrera, L.R. Orozco, G. Wild-Padua, and M.H. Iturriaga. 2010. Effect of storage time on the efficacy of chemical and irradiation treatments to inactivate Salmonella on cilantro (Coriandrum sativum L.). Journal of Food Safety 30: 584–598.

Waje, C.K., S.Y. Jun, Y.K. Lee, et al. 2009. Microbial quality assessment and pathogen inactivation by electron beam and gamma irradiation of commercial seed sprouts. Food Control 20: 200–204.

Wilson, J.E. 1974. Irradiation of polymers: Crosslinking versus scission. Ch 7. In Radiation chemistry of monomers, polymers and plastics. New York: Marcel Dekker.

Acknowledgments

The author extends thanks to David Geveke, Ph.D., and Joseph Sites, PE, for their thoughtful reviews of this manuscript. Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the United States Department of Agriculture (USDA), which is an equal opportunity provider and employer.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Science+Business Media, LLC, part of Springer Nature

About this chapter

Cite this chapter

Niemira, B.A. (2018). Safety and Quality of Irradiated Fruits and Vegetables. In: Rosenthal, A., Deliza, R., Welti-Chanes, J., Barbosa-Cánovas, G. (eds) Fruit Preservation. Food Engineering Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4939-3311-2_14

Download citation

DOI: https://doi.org/10.1007/978-1-4939-3311-2_14

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4939-3309-9

Online ISBN: 978-1-4939-3311-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)