Abstract

The last ten years have witnessed significant developments in the design and fabrication of advanced composite materials. By integrating contemporary design concepts—such as a toughened resin system and radial ply architecture—with innovative processing technology, thick, geometrically complex structures can now be produced which possess the ability to withstand a considerably hostile end-use environment. The same intrinsic material attributes that allow such a high degree of performance, however, also serve to make the non-destructive evaluation (NDE) of such a structure very challenging.

Traditional radiographic methods, for example, are inadequate because of the superposition problem inherent in thick, irregularly shaped structures. Other techniques such as pulse echo ultrasonics fall short due to a variety of factors related to the heterogeneous, anisotropic nature of the material. While computed tomography (CT) has been used with great success in detecting processing anomalies, it too has limitations in a high rate production environment because of throughput constraints; moreover, CT will only provide information based upon relative material density. In short, the in-service NDE of a thick composite structure requires a novel solution.

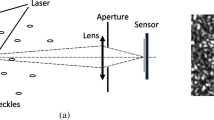

This paper describes an innovative acousto-ultrasonic (AU) approach to production NDE whereby a thick composite segment can be rapidly evaluated with respect to a number of processing parameters including part consolidation and cure/undercure, as well as the presence of delaminations and foreign matter. A series of ultrasonic waveforms are input/acquired using a multiple probe configuration which surrounds the structure. Digital signal processing is utilized to extract pertinent waveform discriminators, and pattern recognition theory is then applied to classify the respective features based upon the results obtained from a learning set of signals taken from an assortment of “good” and “bad” structures. The significance of this platform is that it can be modified to adapt to changing material requirements throughout the production life-cycle; and more importantly, it provides a way to assess a number of different material attributes through a single interrogation process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

A. Vary and K. J. Bowles, An Ultrasonic-Acoustic Technique for Nondestructive Evaluation of Fiber Composite Quality, Poly Enerng & Sc., 19:373 (1979)

W. S. Meisel, Computer-Oriented Approaches to Pattern Recognition„ Academic Press, (1972)

P. A. Dickstein, “Integrated Statistical Processing of NDE Signals for Class Discrimination”, Research in Nondestructive Evaluation, Vol. 4, No. 2, 1992, Springer International

R. O. Duda and P. E. Hart Pattern Classification and Scene Analysis, Wiley, New York, (1973)

J. A. Brunk, C. J. Valenza and M. C. Bhardwaj, Applications and Advantages of Dry Coupling Ultrasonic Transducers for Materials Characterization, in Acousto-Ultrasonics: Theory and Application, edited by John C. Duke, Jr., Plenum Press, New York and London, 221, (1988)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1994 Springer Science+Business Media New York

About this chapter

Cite this chapter

Gill, T.J., Bartos, A.L. (1994). An Acousto-Ultrasonic Platform for the Quality Assessment of Thick Radial Ply Composite Structures. In: Green, R.E., Kozaczek, K.J., Ruud, C.O. (eds) Nondestructive Characterization of Materials VI. Springer, Boston, MA. https://doi.org/10.1007/978-1-4615-2574-5_67

Download citation

DOI: https://doi.org/10.1007/978-1-4615-2574-5_67

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4613-6100-8

Online ISBN: 978-1-4615-2574-5

eBook Packages: Springer Book Archive