Abstract

Shrinkage of biological materials is generally considered to be one of the key issues that results from drying. It is often highly prejudicial for both the quality of the material and the performance of the process. First, shrinkage results in a smaller exchange surface and hinders the diffusion of moisture through the porous structure, for both dehydration and rehydration processes. The dried products are not suitable for grinding and the resulting powders, which generally consist of compact granules and a low specific surface area, are characterized by a lack of uniformity in terms of particle diameter. Secondly, the compact structure of dried food material usually triggers poor organoleptic quality.

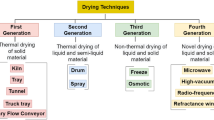

Freeze-drying is the only way to preserve the initial product volume because most of the free water is frozen. However, it is a costly, time-consuming process which only provides a slight improvement in the quality of the structured products so it is of limited value to industry. Thus, it is becoming very important to couple conventional drying processes to appropriate texturing processes. Given this objective, instant controlled pressure drop (DIC) technology could be included in the drying process to provide an appropriate expansion of the structure. DIC generally intensifies the whole drying operation, markedly improving the product quality and the performance of the drying process.

Finally, microbiological contamination and the presence of insects and larvae cause serious problems for a large category of dried, and even freeze-dried, fruits and vegetables. DIC technology can be used as a ultrahigh temperature (UHT) treatment to decontaminate these foodstuffs. Such dried, expanded, and completely decontaminated products can be used as highly nutritional “snacks.” They can also be ground easily to produce expanded granule powders with excellent sensory, nutritional, functional, and textural properties.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abdulla G, Belghit A, Allaf K (2009) Impact of instant controlled pressure drop treatment on moisture adsorption isotherm of cork granules. Drying Technol 27(2):237–247. doi:10.1080/07373930802605990

Al Haddad M (2007) Contribution théorique et modélisation des phénomènes instantanée dans les opérations d’autovaporisation et de déshydratation. Université de La Rochelle, La Rochelle

Al Haddad M, Mounir SM, Sobolik V, Allaf K (2008) Fruits and vegetables drying combining hot air, DIC technology and microwaves. Int J Food Eng 4(6):Article 9

Albitar N, Mounir S, Besombes C, Allaf K (2011) Improving the drying of onion using the instant controlled pressure drop technology. Drying Technol 29(9):993–1001. doi:10.1080/07373937.2010.507912

Allaf K (1982) Transfer phenomena and industrial applications. Lebanese University Faculty of Science, Beirut

Allaf K (2009) The new instant controlled pressure-drop DIC technology. In: Chemat F (ed) Essential oils and aromas: green extraction and application. Har Krishan Bhalla and Sons, New Delhi, pp 85–121

Al-Muhtaseb AH, McMinn WAM, Magee TRA (2004) Water sorption isotherms of starch powders: part 1: mathematical description of experimental data. J Food Eng 61(3):297–307. doi:10.1016/s0260-8774(03)00133-x

Alonzo-Macías M (2013) Comparative study of strawberry drying processes: hot air drying, freeze-drying and swell drying, application on the biological compounds preservation. University of La Rochelle, La Rochelle

Arslan N, Togrul H (2006) The fitting of various models to water sorption isotherms of tea stored in a chamber under controlled temperature and humidity. J Stored Prod Res 42(2):112–135. doi:10.1016/j.jspr.2005.01.001

Baker E, Mustakas G (1973) Heat inactivation of trypsin inhibitor, lipoxygenase and urease in soybeans: effect of acid and base additives. J Am Oil Chem Soc 50(5):137–141. doi:10.1007/bf02640466

Bhandari BR, Howes T (1999) Implication of glass transition for the drying and stability of dried foods. J Food Eng 40(1–2):71–79. doi:10.1016/s0260-8774(99)00039-4

Bonazzi C, Bimbenet JJ (2003) Séchage des produits alimentaires - Principes. Techniques de l’Ingénieur F-3:1–14

Cano-Chauca M, Stringheta PC, Ramos AM, Cal-Vidal J (2005) Effect of the carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. Innov Food Sci Emerg Technol 6(4):420–428. doi:10.1016/j.ifset.2005.05.003

Changrue V (2006) Hybrid (osmotic, microwave-vacuum) drying of strawberries and carrots. McGill University, Montreal

Chen R-H, Chow LC, Navedo JE (2002) Effects of spray characteristics on critical heat flux in subcooled water spray cooling. Int J Heat Mass Transf 45(19):4033–4043. doi:10.1016/s0017-9310(02)00113-8

Chua KJ, Chou SK, Ho JC, Mujumdar AS, Hawlader MNA (2000) Cyclic air temperature drying of guava pieces: effects on moisture and ascorbic acid contents. Food Bioprod Process 78(2):72–78. doi:10.1205/096030800532761

Chua KJ, Mujumdar AS, Chou SK (2003) Intermittent drying of bioproducts—an overview. Bioresour Technol 90(3):285–295. doi:10.1016/s0960-8524(03)00133-0

Crank J (1975) The mathematics of diffusion. Oxford University Press, Oxford

De Boland AR, Garner GB, O’Dell BL (1975) Identification and properties of phytate in cereal grains and oilseed products. J Agric Food Chem 23(6):1186–1189. doi:10.1021/jf60202a038

Dickerson RW (1969) Thermal properties of foods. In: Tressler DK, Van Arsdel WB, Copley MJ (eds) The freezing preservation of food, vol 2, 4th edn. AVI Publishing Company, Westport, pp 26–51

Donsì G, Ferrari G, Nigro R, Di Matteo P (1998) Combination of mild dehydration and freeze-drying processes to obtain high quality dried vegetables and fruits. Food and Bioproducts Process 76(4):181–187. doi:10.1205/096030898532061

Durakova AG, Menkov ND (2004) Moisture sorption characteristics of rice flour. Food Nahrung 48(2):137–140. doi:10.1002/food.200300387

Farroni AE, Matiacevich SB, Guerrero S, Alzamora S, del Pilar BM (2008) Multi-level approach for the analysis of water effects in corn flakes. J Agric Food Chem 56(15):6447–6453. doi:10.1021/jf800541f

Grabowski S, Marcotte M (2003) Pretreatment efficiency in osmotic dehydration of cranberries. In: Welti-Chanes J, Velez-Ruiz JF (eds) Transport phenomena in food processing. Food preservation technology. CRC Press, Boca Raton. doi:10.1201/9781420006261.ch5

Haas GJ, Prescott HE, Cante CJ (1974) On rehydration and respiration of dry and partially dried vegetables. J Food Sci 39(4):681–684. doi:10.1111/j.1365-2621.1974.tb17956.x

Haddad J, Allaf K (2007) A study of the impact of instantaneous controlled pressure drop on the trypsin inhibitors of soybean. J Food Eng 79(1):353–357. doi:10.1016/j.jfoodeng.2006.01.066

Haddad J, Greiner R, Allaf K (2007) Effect of instantaneous controlled pressure drop on the phytate content of lupin. LWT—Food Sci Technol 40(3):448–453

Iguedjtal T, Louka N, Allaf K (2008) Sorption isotherms of potato slices dried and texturized by controlled sudden decompression. J Food Eng 85(2):180–190. doi:10.1016/j.jfoodeng.2007.06.028

Karathanos V (1993) Collapse of structure during drying of celery. Drying Technol 11(5):1005–1023. doi:10.1080/07373939308916880

Katz EE, Labuza TP (1981) Effect of water activity on the sensory crispness and mechanical deformation of snack food products. J Food Sci 46(2):403–409. doi:10.1111/j.1365-2621.1981.tb04871.x

Kaymak-Ertekin F, Gedik A (2004) Sorption isotherms and isosteric heat of sorption for grapes, apricots, apples and potatoes. LWT—Food Sci Technol 37(4):429–438. doi:10.1016/j.lwt.2003.10.012

Kerdpiboon S, Devahastin S, Kerr WL (2007) Comparative fractal characterization of physical changes of different food products during drying. J Food Eng 83(4):570–580. doi:10.1016/j.jfoodeng.2007.03.039

Kostaropoulos AE, Saravacos GD (1997) Thermal diffusivity of granular and porous foods at low moisture content. J Food Eng 33(1–2):101–109. doi:10.1016/S0260-8774(97)00036-8

Maritza AM, Sabah M, Anaberta CM, Montejano-Gaitán JG, Allaf K (2012) Comparative study of various drying processes at physical and chemical properties of strawberries (fragariavarcamarosa). Procedia Eng 42:297–312. doi:10.1016/j.proeng.2012.07.418

Mayor L, Sereno AM (2004) Modelling shrinkage during convective drying of food materials: a review. J Food Eng 61(3):373–386. doi:10.1016/s0260-8774(03)00144-4

Mazza G (1982) Moisture sorption isotherms of potato slices. Int J Food Sci Technol 17(1):47–54. doi:10.1111/j.1365-2621.1982.tb00158.x

Mounir S, Allaf K (2008) Three-stage spray drying: New process involving instant controlled pressure drop. Drying Technol 26(4):452–463. doi:10.1080/07373930801929334

Mounir S, Allaf K (2009) Study and modelling of dehydration and rehydration kinetics within porous medium. Association Française de Séchage pour l’Industrie et l’Agriculture, Lyon

Mounir S, Allaf K (2012) Enhancing hot air drying of chicken meat by instant controlled pressure drop DIC. Paper presented at the 1st Middle-East Drying Conference (MEDC2012), Mahshar, 19–20 Feb 2012

Mounir S, Besombes C, Al-Bitar N, Allaf K (2011a) Study of instant controlled pressure drop DIC—treatment in manufacturing snack and expanded granule powder of apple and onion. Drying Technol 29(3):331

Mounir S, Besombes C, Albitar N, Allaf K (2011b) Study of instant controlled pressure drop DIC treatment in manufacturing snack and expanded granule powder of apple and onion. Drying Technol 29(3):331–341. doi:10.1080/07373937.2010.491585

Mounir S, Halle D, Allaf K (2011c) Characterization of pure cheese snacks and expanded granule powders textured by the instant controlled pressure drop (DIC) process. Dairy Sci Technol 91(4):441–455. doi:10.1007/s13594-011-0023-8

Mounir S, Allaf T, Mujumdar AS, Allaf K (2012) Swell drying: coupling instant controlled pressure drop DIC to standard convection drying processes to intensify transfer phenomena and improve quality—an overview. Drying Technol 30(14):1508–1531. doi:10.1080/07373937.2012.693145

Mujumdar AS, Menon AS (1995) Drying of solids. In: Mujumdar AS (ed) Handbook of industrial drying, 2nd edn. Marcel Dekker, New York, pp 1–46

Pimpaporn P, Devahastin S, Chiewchan N (2007) Effects of combined pretreatments on drying kinetics and quality of potato chips undergoing low-pressure superheated steam drying. J Food Eng 81(2):318–329. doi:10.1016/j.jfoodeng.2006.11.009

Prachayawarakorn S, Tia W, Plyto N, Soponronnarit S (2008) Drying kinetics and quality attributes of low-fat banana slices dried at high temperature. J Food Eng 85(4):509–517. doi:10.1016/j.jfoodeng.2007.08.011

Rackis JJ, Wolf WJ, Baker EC (1986) Protease inhibitors in plant foods: content and inactivation. Adv Exp Med Biol 199:299–347

Rahman MS (2001) Toward prediction of porosity in foods during drying: a brief review. Drying Technol 19(1):1–13. doi:10.1081/drt-100001349

Rahman MS, Sablani SS (2003) Structural characteristics of freeze-dried abalone: porosimetry and puncture test. Food Bioprod Process 81(4):309–315

Rahman MS, Chen XD, Perera CO (1997) An improved thermal conductivity prediction model for fruits and vegetables as a function of temperature, water content and porosity. J Food Eng 31(2):163–170. doi:10.1016/s0260-8774(96)00060-x

Roos Y, Karel M (1991) Phase transitions of mixtures of amorphous polysaccharides and sugars. Biotechnol Prog 7(1):49–53. doi:10.1021/bp00007a008

Ruiz-López II, Ruiz-Espinosa H, Luna-Guevara ML, García-Alvarado MA (2011) Modeling and simulation of heat and mass transfer during drying of solids with hemispherical shell geometry. Comput Chem Eng 35(2):191–199. doi:10.1016/j.compchemeng.2010.05.007

Sandhu KS, Parhawk B (2002) Studies on the preparation of dehydrated potato cubes. J Food Sci Technol (Mysore) 39(6):594–602

Setyopratomo P, Fatmawati A, Sutrisna PD, Savitri E, Allaf K (2011) The dehydration kinetics, physical properties and nutritional content of banana textured by instantaneous controlled pressure drop. Asia-Pacific J Chem Eng 7:726–732. doi:10.1002/apj.624

Singh S, Raina CS, Bawa AS, Saxena DC (2006) Effect of pretreatments on drying and rehydration kinetics and color of sweet potato slices. Drying Technol 24(11):1487–1494. doi:10.1080/07373930600952834

Sulaiman I (2013) Approches fondamentales et expérimentales des processus d’autovaporisation et de modification structurelle de matériaux surchauffés pendant la détente instantanée contrôlée vers le vide. Université de la Rochelle, La Rochelle

Téllez-Pérez C (2013) Valorization of Mexican agriculture by preservation and drying by instant autovaporization; case of green pepper. University of La Rochelle, La Rochelle

Téllez-Pérez C, Sabah MM, Montejano-Gaitán JG, Sobolik V, Martínez CA, Allaf K (2012) Impact of instant controlled pressure drop treatment on dehydration and rehydration kinetics of green Moroccan pepper (Capsicum annuum). Procedia Eng 42:1077–1101. doi:10.1016/j.proeng.2012.07.491

Waldron KW, Smith AC, Parr AJ, Ng A, Parker ML (1997) New approaches to understanding and controlling cell separation in relation to fruit and vegetable texture. Trends Food Sci Technol 8(7):213–221. doi:10.1016/S0924-2244(97)01052-2

Whorton C, Reineccius GA (1995) Evaluation of the mechanisms associated with the release of encapsulated flavor materials from maltodextrin matrices. In: Encapsulation and controlled release of food ingredients, vol 590. ACS Symposium Series. American Chemical Society, pp 143–160. doi:10.1021/bk-1995-0590.ch013

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media New York

About this chapter

Cite this chapter

Mounir, S., Téllez-Pérez, C., Alonzo-Macías, M., Allaf, K. (2014). Swell-Drying. In: Allaf, T., Allaf, K. (eds) Instant Controlled Pressure Drop (D.I.C.) in Food Processing. Food Engineering Series. Springer, New York, NY. https://doi.org/10.1007/978-1-4614-8669-5_1

Download citation

DOI: https://doi.org/10.1007/978-1-4614-8669-5_1

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4614-8668-8

Online ISBN: 978-1-4614-8669-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)