Abstract

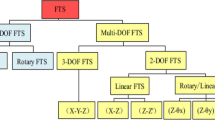

Fast tool servos can be used in conjunction with diamond turning machines to produce precision contoured surfaces. This paper presents an overview of fast tool servo (FTS) technology and applications. A literature review groups the FTS devices by operating principle and performance. A new class of FTS is described in detail which uses a flux-steering actuator to achieve unprecedented performance levels. This Ultra-Fast Tool Servo (UFTS) has 30 μm stroke, 23 kHz closed-loop bandwidth, acceleration of 5000 m/sec2, and positioning noise of 2.1 nm RMS while cutting.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

4 References

Y. Altintas and A. Woronko. A piezo tool actuator for precision turning of hardened shafts. Annals of the CIRP, 51(1), 2002.

Walter Baar, Herbert Koehler, and Walter Muecke. Engraving device for a printing from engraving machine. US Patent 3964382, June 1976.

A.E. Barton. Rubber bearings for precision positioning systems. MS thesis, M.I.T., Department of Mechanical Engineering, September 2005.

A.E. Barton and D. L. Trumper. Rubber bearings and their applicability in precision machines. Proceedings from ASPE 2005 Annual Meeting, October 2005.

E. Brinksmeier and W. Preuss. Complex surfaces-applications and generation by diamond machining. Proceedings of the ASPE 1997 Annual Meeting, 1997.

J. F. Cutttino. Performance optimization of a fast tool servo for single-point diamond. IEEE/ASME Trans. on Mechatronics, 4(2), June 1999.

S. Douglass. A machining system for turning nonaxis-symmetric surfaces. PhD dissertation, the University of Tennessee, Knoxville, 1983.

T. A. Dow, M. H. Miller, and P.J. Falter. Application of a fast tool servo for diamond turning of nonrotationally symmetric surfaces. Precision Engineering, 13(4), 1991.

H. Eda. Ultra-precise machine tool equipped with a giant magnetostriction actuator-development of new materials and their application. CIRP annals, 41(1), 1992.

Chris J. Evans and James B. Bryan. “structured”, “textured” or “engineered” surfaces. CIRP annals, 48(2), 1999.

K. J. Falter and David H. Youden. The characterization and testing of a long stroke fast tool servo. International Progress in Precision Engineering: Proceedings of 8th International Precision Engineering Seminar, 1995.

P. Falter and T. Dow. A diamond-turning apparatus for fabrication of non-rotationally symmetric surface generation. Proceedings of the International Congress for Ultraprecision Technology, Aachen, pages 187–201, 1988.

II G. M. Moorefield. Generation of rotationally asymmetric optical surfaces using a fast tool servo. Proc. of ASPE 1995 annual meeting.

W. Greene and D. Shinstock. Design of a linear voice coil actuator for fast tool servo applications. Proc. of ASPE 1997 annual meeting.

H. M. Gutierrez and P. I. Ro. Parametric modeling and control of a long-range actuator using magnetic servo-levitation. IEEE Tran. on Magnetics, 34(5), 1998.

H. M. Gutierrez and P. I. Ro. Sliding-mode control of a nonlinear-input system: application to a magnetically levitated fast tool servo. IEEE Tran. on Industrial Electronics, 45(6), 1998.

R. D. Hanson and T.-C. Tsao. Periodic sampling interval repetitive control and its application to variable spindle speed non-circular turning process. ASME Journal of Dynamic Systems, Measurement and Control, Vol. 122, pages 560–566, September 2000.

Y. Hara, S. Motonishi, K. Yoshida, and N. Ikawa. A new micro-cutting device with high stiffness and resolution. Annals of the CIRP, 39(1), 1990.

B. Jared. Fabrication of surface perturbation on inertial confinement fusion targets. Proc. of ASPE 1996 annual meeting.

Stephen Joseph Ludwick Jr. A Rotary Fast Tool Servo for Diamond Turning of Asymmetric Optics. PhD dissertation, M.I.T., Department of Mechanical Engineering, June 1999.

D. H. Kim and T.-C. Tsao. Robust performance control of electrohydraulic actuators for electronic cam motion generation. IEEE Transactions on Control Systems Technology, Vol. 8, pages 220–227, March 2000.

E. Kouno. A fast reponse piezoelectric actuator for servo correction of systematic errors in precision machining. Annals of the CIRP, 33(1):369–372, 1984.

D. Liu. Surface texture improvement in the turning process via application of a magnetostrictively actuatored tool holder. ASME Journal of DSMC, 120, 1998.

Xiaodong Lu. Electromagnetically-Driven Ultra-Fast Tool Servos for Diamond Turning. PhD dissertation, M.I.T., Department of Mechanical Engineering, September 2005.

Xiaodong Lu and David L. Trumper. Electromagnetically driven fast tool servo. Proceedings from ASPE 2003 Annual Meeting, pages 103–106, 2003.

Xiaodong Lu and David L. Trumper. Electromagnetically driven ultrafast tool servo. Proceedings from ASPE 2004 Annual Meeting, pages 269–272, 2004.

Xiaodong Lu and David L. Trumper. High bandwidth fast tool servo control. American Control Conference 2004, June 2004.

Xiaodong Lu and David L. Trumper. Ultra fast tool servos for diamond turning. Annals of the CIRP, 54(1):2005.

S. Ludwick and D. L. Trumper. Design of a rotary fast tool servo for ophthalmic lens fabrication. Precision Engineering, 23(4):253–259, 1999.

R. C. Montesanti and D. L. Trumper. High bandwidth short stroke rotary fast tool servo. Proceedings from ASPE 2003 Annual Meeting, pages 115–118, 2003.

R. C. Montesanti and D. L. Trumper. A 10 kHz short-stroke rotary fast tool servo. Proceedings from ASPE 2004 Annual Meeting, October 2004.

Richard Montesanti. High Bandwidth Rotary Fast Tool Servos and a Hybrid Rotary/Linear Electromagnetic Actuator. PhD dissertation, M.I.T., Department of Mechanical Engineering, September 2005.

Y. Okazaki. A micro-positioning tool post using a piezoelectric actuator for diamond turning machines. Precision Engineering, 12(3), 1990.

Yuichi Okazaki. Fast tool servo system and its application to three dimensional fine surface figures. Proc. of ASPE 1998 annual meeting.

S. R. Patterson and E. B. Magrab. The design and testing of a fast tool servo for diamond turning. Precision Engineering, 7(3):123–128, 1985.

J. D. Rasmussen. Dynamic variable depth of cut machining using piezoelectric actuators. International Journal of Machine Tools and Manufacture, 34(3):379–392, 1994.

P. Schellekens. Design for precision: Current status and trends. Annals of the CIRP, 47(2):557–586, 1998.

B. Stancil, H. Gutierrez, and P. Ro. Design of a long range fast tool servo system using magnetic servo levitation. Proceedings from ASPE 1995 Annual Meeting, pages 301–304, 1995.

M. W. Todd and J. F. Cuttino. Development of a long range, traction drive fast tool servo for diamond turning applications. Proc. of ASPE 1997 annual meeting.

H. Tran and D. DeBra. Design of a fast short-stroke hydraulic actuator. Annals of the CIRP, 43(1):469–472, 1994.

T.-C. Tsao and M. Tomizuka. Robust adaptive and repetitive digital tracking control and application to a hydraulic servo for noncircular machining. ASME Journal of Dynamic Systems, Measurement, and Control, Vol. 116:1, pages 24–32, February 2000.

X. Wang. Experimental research on the linear motor micro-feed devices with high frequency response, long travel and high accuracy. Annals of the CIRP, 40(1):379–382, 1991.

M. H. Weck. A new hybrid concept for a long stroke fast tool servo system. Proc. of ASPE 1995 annual meeting, 1995.

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 2007 Springer-Verlag London Limited

About this paper

Cite this paper

Trumper, D.L., Lu, X. (2007). Fast Tool Servos: Advances in Precision, Acceleration, and Bandwidth. In: Towards Synthesis of Micro-/Nano-systems. Springer, London . https://doi.org/10.1007/1-84628-559-3_2

Download citation

DOI: https://doi.org/10.1007/1-84628-559-3_2

Publisher Name: Springer, London

Print ISBN: 978-1-84628-558-5

Online ISBN: 978-1-84628-559-2

eBook Packages: EngineeringEngineering (R0)