Abstract

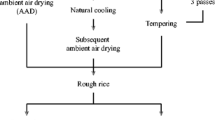

Infrared radiation (IR) heating has a promising potential to achieve high drying rate, energy saving, effective disinfestation, and disinfection of rough rice. It can also inactivate lipase and extend the storage lives of both rough and brown rice. Moreover, IR can effectively stabilize the rice bran and improve its utilization without affecting the quality of rice bran oil. Consequently, through the recent investigations about IR heating on rice, it has proven the feasibility of simultaneous drying, disinfestation, disinfection, and stabilization. This chapter summarizes the drying characteristics, milling quality, sensory quality, effectiveness of disinfestation and disinfection, rice bran stabilization, and storage stability of rough rice under IR heating. The outcomes of recent studies on rice drying by using IR heating have clearly revealed that a high heating rate, fast drying, good quality, and improved food safety can be achieved. IR drying provides a potential to store brown rice instead of rough rice to retain all benefits with reduced costs. Additionally, IR drying could effectively maintain the stability of physicochemical characteristics of rice during storage. It has been confirmed that IR heating followed by natural cooling should be an effective approach for designing IR rough rice dryers.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abdelmotaleb, I.A., H.M. Sorour, M.M. El-Kholy, et al. 2001. A study on different integrated drying-milling systems for rice. MISR Journal of Agricultural Engineering 18 (3): 492–510.

Abe, T., and T.M. Afzal. 1998. Heat and mass transfer characteristics of barley during far infrared radiation drying. In: Proceedings of 2nd international workshop on ‘‘Control applications in post-harvest and processing technology” (CAPPT’98), Budapest, Hungary.

Afzal, T. M., and T. Abe. 1997. Combined convection and far-infrared radiation drying of rough rice. ASAE Paper No. 9760972. St. Joseph MI.

Afzal, T.M., T. Abe, and Y. Hikida. 1999. Energy and quality aspects during combined FIR-convection drying of barley. Journal of Food Engineering 42: 177–182.

Almeida, M.I., N.G. Almeida, K.L. Carvalho, et al. 2012. Cooccurrence of aflatoxins B1, B2, G1 and G2, ochratoxin A, zearalenone, deoxynivalenol, and citreoviridin in rice in Brazil. Food Additives & Contaminants. Part A, Chemistry, Analysis, Control, Exposure and Risk Assessment 29: 694–703.

Amaratunga, K., Z. Pan, X. Zheng, et al. 2005. Comparison of drying characteristics and quality of rough rice dried with infrared and heated air. ASAE Paper No. 056005, 1–10. St. Joseph, MI, USA.

Andrews, S. 1996. Evaluation of surface disinfection procedures for enumerating fungi in foods: A collaborative study. International Journal of Food Microbiology 29: 177–184.

Bal, S., F.T. Wratten, J.L. Chesnen, et al. 1970. An analytical and experimental study of radiant heating of rice grain. Transactions of the ASAE, 13 (5): 644–652.

Bala, B.K. 1997. Drying and storage of cereal grains, 93–92. USA: Science publishers INC.

Ban, T. 1971. Rice cracking in high rate drying. Japan Agricultural Research Quarterly 6 (2): 13–116.

Beuchat, L.R. 1998. Surface decontamination of fruits and vegetables eaten raw: A review. http://www.who.int/foodsafety/publications/fs_management/surfac_decon/en/.

Bilowicka, E. 1960. Research concerning the drying of small seeds by infrared radiation. In International drying conference. Institute of Mechanization and Electrification of Agriculture, Warsaw, Poland.

Carl, W.H. 1980. Drying and storage of agricultural crops. Westport, Connecticut, USA: AVI publishing company, JNC.

Champagne, E.T., B.G. Lyon, B.K. Min, et al. 1998. Effects of postharvest processing on texture profile analysis of cooked rice. Cereal Chemistry 75 (2): 181–186.

Chen, Y. 1997. A thin layer equation for intermittent drying of rough rice. ASAE Paper No. 976071. St. Joseph, MI, USA.

Chen, H., T.J. Siebenmorgen, and B.P. Marks. 1997. Relating drying rate constant to head rice yield reduction of long-grain rice. Transactions of the ASAE 40 (4): 1133–1139.

Chua, K.J., and S.K. Chou. 2003. Low-cost drying methods for developing countries. Trends in Food Science and Technology 14: 519–528.

Cnossen, A.G., and T.J. Siebenmorgen. 2000. The glass transition temperature concept in rice drying and tempering: effect on milling quality. Transactions of the ASAE 43 (6): 1661–1668.

Cnossen, A.G., T.J. Siebenmorgen, W. Yang, et al. 2000. The glass transaction temperature concept in rice drying and tempering effect on milling quality. Transactions of the ASAE 43 (6): 1661–1667.

Cnossen, A.G., M.J. Jimenez, and T.J. Siebenmorgen. 2003. Rice fissuring response to high drying and tempering temperatures. Journal of Food Engineering 59: 61–69.

David, L.C., and B.D. Webb. 1971. Effect of the method of dryer operation on performance and on the milling and cooking characteristics of rice. Transactions of the ASAE 14 (1): 142–145.

Ding, D., R. Khir, Z.L. Pan, et al. 2015a. Improvement in shelf life of rough and brown rice using infrared radiation heating. Food and Bioprocess Technology 8 (5): 1149–1159.

Ding, D., R. Khir, Z.L. Pan, et al. 2015b. Effect of infrared and conventional drying methods on physicochemical characteristics of stored white rice. Cereal Chemistry 92 (5): 441–448.

Ding, D., R. Khir, Z.L. Pan, et al. 2016. Improvement in storage stability of infrared-dried rough rice. Food and Bioprocess Technology 9 (6): 1010–1020. https://doi.org/10.1007/s11947-016-1690-5.

Dostie, M., J.N. Seguin, D. Maure, et al. 1989. Preliminary measurements on the drying of thick porous materials by combination of intermittent infrared and continuous convection heating. In Mujumdar, A.S., and M.A. Roques. (Eds.) Drying’89. New York, USA: Hemisphere.

Donald, B.B., W.B. Fred, and W.H. Carl. 1992. Drying and storage of grains and oilseeds. New York, USA: Van Nostr and Reinold.

Elaine, T.C. 2004. Rice chemistry and technology, 3rd ed, 77–100. USA: American Association of Cereal Chemists.

Elena, S.B., C. Magda, M.R. Ignacio, et al. 2013. Aflatoxin (B1, B2, G1, and G2) contamination in rice of Mexico and Spain from local sources or imported. Journal of Food Science 78: 1822–1829.

Fan, J., and B.P. Marks. 1999. Effects of rough rice storage conditions on gelatinization and retrogradation properties of rice flours. Cereal Chemistry 76 (6): 894–897.

Fu, W.R., and W.R. Lien. 1998. Optimization of far infrared heat dehydration of shrimp using RSM. Journal of Food Science 63 (1): 80–83.

Ginzburg, A.S., and A. Grochowski. 1969. Application of infrared radiation in food industry. London, UK: Leonard Hill.

Hall, C.W. 1962. Theory of infrared drying. Transactions of the ASAE 5 (1): 14–16.

Hallstrom, B., C. Skjodebrand, and C. Traardh. 1988. Heat transfer and food products. London: Elsevier Applied Science.

Hasatani, M., Y. Itaya, and K. Miura. 1988. Hybrid drying of granular materials by combined radiative and convective heating. Drying Technology 6 (1): 43–68.

Hebbar, H.U., and N.K. Rostagi. 2001. Mass transfer during infrared drying of cashew kernel. Journal of Food Engineering 47: 1–5.

Hebbar, H.U., K.H. Vishwanathan, and M.N. Ramesh. 2004. Development of combined infrared and hot air dryer for vegetables. Journal of Food Engineering 65: 557–563.

Henderson, S.M., and R.L. Perry. 1976. Agricultural process engineering. Westport, Connecticut, USA: AVI Publishing Corporation Inc.

Helmy, M.A., S.M. Radwan, and M. El-Kholy. 1995. Effect of different paddy drying methods of rice milling quality. MISR Journal of Agricultural Engineering 12 (2): 496–509.

Hindy, F.I., I.A. Abdelmotaleb, and M.I. Shoughy. 2001. Technology of in-storage drying of rice by using ambient air under local conditions. MISR Journal of Agricultural Engineering 18 (3): 585–604.

Hussaini, A.M., F.D. Michael, B.N. Patrick, et al. 2011. Natural multioccurrence of mycotoxins in rice from Niger state, Nigeria. Mycotoxin Research 27: 97–104.

Ito, K., and C.S. Han. 1995. Drying of agricultural products using long wave infrared radiation–Drying of welsh onion. Journal of the Society of Agricultural Structures Japan 26 (2): 89–96.

Kaminski, T.A., A. Brackmann, L.P. da Silva, et al. 2013. Changes in culinary, viscoamylographic and sensory characteristics during rice storage at different temperatures. Journal of Stored Products Research 53 (2): 37–42.

Khir, R., Z.L. Pan, A. Salim, et al. 2011. Moisture diffusivity of rough rice under infrared radiation drying. LWT—Food Science and Technology 44 (4): 1126–1132.

Khir, R., Z.L. Pa, J.F. Thompson, et al. 2014. Moisture removal characteristics of thin layer rough rice under sequenced infrared radiation heating and cooling. Journal of Food Processing and Preservation 38 (1): 430–440.

Kunze, O.R., and M.S.U. Choudhury. 1972. Moisture adsorption related to the tensile strength of rice. Cereal Chemistry 49 (6): 684–696.

Kunze, O.R. 1979. Fissuring of the rice grain after heated air drying. Transactions of the ASAE 22 (5): 1197–1202, 1207.

Kunze, O.R., and D.L. Calderwood. 1985. Rough rice drying. In Rice: Chemistry and technology, ed. E.T. Champagne, 233–263. St. Paul, Minn: American Association of Cereal Chemists.

Lai, X.W., R.C. Liu, C.Q. Ruan, et al. 2015. Occurrence of aflatoxins and ochratoxin A in rice samples from six provinces in China. Food Control 50: 401–404.

Li, X., and Z.L. Pan. 2013. Dry-peeling of tomato by infrared radiative heating: Part I. Model development. Food and Bioprocess Technology 7 (7): 1996–2004.

Masamure, A., H. Sado, T. Hoda, et al. 1998. Drying of potato by far infrared radiation. Nippon Shokuhin Kogyo Gakkaishi 35 (5): 309–314.

National Advisory Committee on Microbiological Criteria for Foods. 1999. Microbiological safety evaluations and recommendations on sprouted seeds. International Journal of Food Microbiology 52: 123–153.

Nguyen, L.H., R.H. Driscoll, and G. Srzednicki. 2001. Drying of high moisture content paddy in a pilot scale triangular spouted bed dryer. Drying Technology: An International Journal 19 (2): 375–387.

Nowak, D., and P.P. Lewicki. 2004. Infrared drying of apple slices. Innovative Food Science and Emerging Technologies 5 (3): 353–360.

Ok, H.E., D.M. Kim, D. Kim, et al. 2014. Mycobiota and natural occurrence of aflatoxin, deoxynivalenol, nivalenol and zearalenone in rice freshly harvested in South Korea. Food Control 37: 284–291.

Oyebanji, O.B., O. Nweke, O. Odebunmi, et al. 2009. Simple, effective and economical explant-surface sterilization protocol for cowpea, rice and sorghum seeds. African Journal of Biotechnology 8 (20): 5395–5399.

Paakkonen, K., J. Havento, B. Galambosi, et al. 1999. Infrared drying of herbs. Agricultural and Food Science in Finland 8: 9–27.

Pan, Z., R. Khir, L.D. Godfrey, et al. 2008. Feasibility of simultaneous rough rice drying and disinfestations by infrared radiation heating and rice milling quality. Journal of Food Engineering 84 (3): 469–479.

Pan, Z., and G.G. Atungulu. 2010. Infrared dry blanching. In Infrared heating for food and agricultural processing, ed. Z. Pan and G.G. Atungulu, 169–201. Florida, USA: CRC Press.

Pan, Z., R. Khir, K.L. Bett-Garber, et al. 2011. Drying characteristics and quality of rough rice under infrared radiation heating. Transactions of the ASABE 54 (1): 203–210.

Parrouffe, J. M., M. Dostie, A.S. Mujumdar, et al. 1992. Convective transport in infrared drying. In Proceedings of the 8th international drying symposium. Montreal, Quebec, Canada, 695–703.

Perdon, A., T.J. Siebenmorgan, and A. Mauromoustakos. 2000. Glassy state transition and rice drying: Development of a brown rice state diagram. Cereal Chemistry 77 (6): 708–713.

Person, N.K., and J.W. Sorenson. 1962. Drying hay with infrared radiation. Agricultural Engineering 43 (4): 204–237.

Sakai, N., and T. Hanzawa. 1994. Applications and advances in far-infrared heating in Japan. Trends in Food Science and Technology 5 (11): 357–362.

Salunkhe, D.K., J.K. Chavan, and S.S. Kadam. 1985. Postharvest biotechnology of cereals. Boca Raton, FL: CRC Press.

Sandu, C. 1986. Infrared radiative drying in food engineering: A process analysis. Biotechnology Progress 2 (3): 109–119.

Sharma, G.P., R.C. Verma, and P.B. Pathare. 2005. Thin-layer infrared radiation drying of onion slices. Journal of Food Engineering 67: 361–366.

Siebenmorgan, T.J., W. Yang, and Z. Sun. 2004. Glass transition temperature of rice kernels determined by dynamic mechanical thermal analysis. Transactions of the ASAE 47 (3): 835–839.

Stipe, D.R., F.T. Wratten, and M.F. Miller. 1972. Effects of various methods of handling brown rice on milling and other quality parameters. Louisiana Agricultural Experiment Station Annual Program Rep., Rice Exp. Stn. 113.

Tan, M., K.J. Chus, A.S. Mujumdar, et al. 2001. Effect of osmotic pre-treatment and infrared radiation on drying rate and color changes during drying of potato and pineapple. Drying Technology 19 (19): 2193–2207.

Tananuwong, K., and S. Lertsiri. 2010. Changes in volatile aroma compounds of organic fragrant rice during storage under different conditions. Journal of the Science of Food and Agriculture 90 (10): 1590–1596.

Tilton, E.W., and H.W. Schroeder. 1963. Some effects of infrared irradiation on the mortality of immature insects in kernels of rough rice. Journal of Economic Entomology 56: 727–730.

USDA. 1979. Inspection Handbook for the Sampling, Inspection, Grading, and Certification of Rice. HB918–11. Agriculture Marketing Service, Washington, DC 40 (4): 1133–1139.

Wang, B., R. Khir, Z. Pan, et al. 2014. Effective disinfection of rough rice using infrared radiation heating. Journal of Food Protection 77 (9): 1538–1545.

Wang, T., R. Khir, Z. Pan, et al. 2017. Simultaneous rough rice drying and rice bran stabilization using infrared radiation heating. LWT-Food Science and Technology 78: 281–288.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd. and Zhejiang University Press, Hangzhou

About this chapter

Cite this chapter

Khir, R., Venkitasamy, C., Pan, Z. (2019). Infrared Heating for Improved Drying Efficiency, Food Safety, and Quality of Rice. In: Jia, J., Liu, D., Ma, H. (eds) Advances in Food Processing Technology. Springer, Singapore. https://doi.org/10.1007/978-981-13-6451-8_10

Download citation

DOI: https://doi.org/10.1007/978-981-13-6451-8_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6450-1

Online ISBN: 978-981-13-6451-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)