Abstract

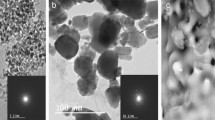

The presented work shows new results of a nanostructured composite material investigation. The fabricated and studied material was in the form of beads based on hydroxyapatite (HA), sodium alginate (Alg) and ZnO particles. The HA was produced under the influence of microwave radiation. The beads of HA–ZnO–Alg were fabricated by dropping slurry into the calcium chloride solution. The main purpose of the research was to study the physical and chemical properties of HA–ZnO–Alg composite and approve its biocompatibility in vitro and in vivo. The morphology and elemental composition investigations were conducted by transmission electron microscopy with diffraction (TEM) and scanning electron microscopy with energy-dispersive analysis (SEM with EDX) methods. It was shown that synthesized HA consists of crystallites with a size of 40 nm. The ZnO inclusion appeared in the form of nanosized crystallites 25 nm in size. The average Ca/P ratio was 2.15, which is close to stoichiometric one.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ong K, Yun M, White J (2015) New biomaterials for orthopedic implants. Orthop Res Rev 7:107–130

Emami-Karvani Z, Chehrazi P (2011) Antibacterial activity of ZnO nanoparticle on Gram-positive and Gram-negative bacteria. African J Microbiol Res 5(12):1368–1373

Elliott JC (2002) Calcium phosphate biominerals. Rev Mineral Geochem 48(1):427–453

Elliott JC (1994) General chemistry of the calcium orthophosphates. In: Studies in organic chemistry

Dorozhkin SV (2015) Calcium orthophosphate deposits: preparation, properties, and biomedical applications. Mater Sci Eng C 55:272–326

Choudhury P, Agrawal DC (2012) Hydroxyapatite (HA) coatings for biomaterials. In: Nanomedicine, pp 84–127

Atri F, Rasaie V, Abbas A, Nikzad S, Fazel Anvari-Yazdi A (2017) Deposition of hydroxyapatite nano-particle on zirconia to improve its bonding. In: 41st annual conference of European Prosthodontic Association PA OP26, 2017, pp 28–29

Wahab R, Mishra A, Yun S-I et al (2010) Antibacterial activity of ZnO nanoparticles prepared via non-hydrolytic solution route. Appl Microbiol Biotechnol 87(5):1917–1925

Raghupathi KR, Koodali RT, Manna AC (2011) Size-dependent bacterial growth inhibition and mechanism of antibacterial activity of zinc oxide nanoparticles. Langmuir 27(7):4020–4028

Grigolo M, Dolzani B, Giannetti P, Tenucci C (2016) Use of a fully-resorbable, biomimetic composite hydroxyapatite as a bone graft substitute for posterolateral spine fusion: a case report. Int J Clin Exp Med 9(11):22458

Sukhodub LB (2014) Metal ions doped chitosan nanoparticles. J Nano Electron Phys 6:04034–04040

Dorozhkin SV (2016) Calcium orthophosphates (CaPO4): occurrence and properties. Prog Biomater 5(1):9–70

Dorozhkin SV (2012) Amorphous calcium orthophosphates: nature, chemistry and biomedical applications. Int J Mater Chem 2(1):19–46

Ślósarczyk A, Paszkiewicz Z, Paluszkiewicz C (2005) FTIR and XRD evaluation of carbonated hydroxyapatite powders synthesized by wet methods. J Mol Struct 744–747:657–661

Tripathi A, Saravanan S, Pattnaik S et al (2012) Bio-composite scaffolds containing chitosan/nano-hydroxyapatite/nano-copper–zinc for bone tissue engineering. Int J Biol Macromol 50(1):294–299

Rokosz K, Hryniewicz T, Pietrzak K, Dudek Ł (2017) Development and SEM/EDS characterization of porous coatings enriched in magnesium and copper obtained on titanium by PEO with ramp voltage. World Sci News 80:29–42

Popovich A, Sufiiarov V, Polozov I et al (2016) Producing hip implants of titanium alloys by additive manufacturing. Int J Bioprinting 2(2):187–193

Pogrebnjak AD, Rogoz VM, Bondar OV et al (2016) Structure and physicomechanical properties of NbN-based protective nanocomposite coatings: a review. Prot Met Phys Chem Surfaces 52(5):802–813

Popovich VA et al (2017) Functionally graded inconel 718 processed by additive manufacturing: crystallographic texture, the anisotropy of microstructure and mechanical properties. Mater Des 114:441–449

Salahshoor M, Guo Y (2012) Biodegradable orthopedic magnesium-calcium (MgCa) alloys, processing, and corrosion performance. Materials (Basel) 5(12):35–155

Popovich AA et al (2016) Use of additive techniques for preparing individual components of titanium alloy joint endoprostheses. Biomed Eng (NY) 50(3):202–205

Pogrebnjak AD, Bratushka SN, Beresnev VM, Levintant-Zayonts N (2013) Shape memory effect and superelasticity of titanium nickelide alloys implanted with high ion doses. Russ Chem Rev 82(12):1135–1159

Pogrebnjak AD, Beresnev VM (2012) Nanocoatings nanosystems nanotechnologies. Bentham Science Publishers

Li X et al (2017) Novel bio-functional magnesium coating on porous Ti6Al4V orthopaedic implants: in vitro and in vivo study. Sci Rep 7(1):40755

Ahmed T, Rack HJ (1999) Low modulus biocompatible titanium base alloys for medical devices. U.S. Patent 5,871,595, issued 16 Feb 1999

Stráský J et al (2017) Increasing the strength of a biomedical Ti-Nb-Ta-Zr alloy by alloying with Fe, Si and O. J Mech Behav Biomed Mater 71:329–336

Kopova I, Stráský J, Harcuba P (2016) Newly developed Ti-Nb-Zr-Ta-Si-Fe biomedical beta titanium alloys with increased strength and enhanced biocompatibility. Mater Sci Eng C 60:230–238

El-Wassefy NA, Reicha FM, Aref NS (2017) Electro-chemical deposition of nano hydroxyapatite-zinc coating on titanium metal substrate. Int J Implant Dent 3(1):39

Hasan A, Waibhaw G, Saxena V et al (2018) Nano-biocomposite scaffolds of chitosan, carboxymethyl cellulose and silver nanoparticle modified cellulose nanowhiskers for bone tissue engineering applications. Int J Biol Macromol 111:923–934

Ito A et al (2005) Zinc-containing tricalcium phosphate and related materials for promoting bone formation. Curr Appl Phys 5(5):402–406

Ito A et al (2002) Zinc-releasing calcium phosphate for stimulating bone formation. Mater Sci Eng C 22(1):21–25

Moseke C, Gelinsky M, Groll J et al (2013) Chemical characterization of hydroxyapatite obtained by wet chemistry in the presence of V, Co, and Cu ions. Mater Sci Eng C 33(3):1654–1661

Gunalan S, Sivaraj R, Rajendran V (2012) Green synthesized ZnO nanoparticles against bacterial and fungal pathogens. Prog Nat Sci Mater Int 22(6):693–700

Kanhed S, Awasthi S, Midha S et al (2018) Microporous hydroxyapatite ceramic composites as tissue engineering scaffolds: an experimental and computational study. Adv Eng Mater 1701062:1–11

Mieshkov AV, Grebenik LI, Ivahnuk TV et al (2016) Antibacterial properties of the nanoparticles with the zinc sulfide quantum dots. IFMBE Proc 55:267–270

Pogrebjak AD, Krivets AS, Dyadyura KA et al (2016) Research of the relief and element composition of the surface coatings based on hydroxyapatite implants from titanium alloys. In: Proceedings of the international conference on Nanomaterials: Application & Properties (NAP), 2016, p 02NABM06

Shypylenko A et al (2016) Effect of ion implantation on the physical and mechanical properties of Ti-Si-N multifunctional coatings for biomedical applications. Mater Des 110:821–829

Saxena V, Hasan A, Pandey LM (2018) Effect of Zn/ZnO integration with hydroxyapatite: a review. Mater Technol 33(2):79–92

Dorozhkin SV, Epple M (2002) Biological and medical significance of calcium phosphates. Angew Chemie Int Ed 41(17):3130–3146

Bhowmick A et al (2015) Development of porous and antimicrobial CTS-PEG-HAP-ZnO nano-composites for bone tissue engineering. RSC Adv 120

Livitska O et al (2016) Copper (II), zinc (II) and copper (II)/zinc (II)-containing carbonate-substituted hydroxyapatite: synthesis, characterization and thermal behavior. Materwiss Werksttech 47(2–3):85–91

Sukhodub S et al (2014) Nanocomposite apatite-biopolymer materials and coatings for biomedical applications. J Nano-Electron Phys 6(2):1–5

Martynyuk OO, Sukhodub LF, Sukhodub LB et al (2016) Structural properties of apatite-biopolymer nanocomposites, doped ZnO. J Nano-Electron Phys 8(4):1–6

Acknowledgements

The present work was carried out under the financial support of the Science Committee of the Ministry of Education and Science of the Republic of Kazakhstan for the targeted financing program “Targeted scientific and technical program of the D. Serikbayev East Kazakhstan State Technical University, focused on the development of new types of products for fabrication at the leading industrial enterprises of the East Kazakhstan region” for 2017–2019 years.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Pogrebnjak, A.D., Sukhodub, L.F., Sukhodub, L., Bondar, O.V., Turlybekuly, A. (2019). ZnO Doped Nanosized Composite Material Based on Hydroxyapatite and Sodium Alginate Matrix. In: Pogrebnjak, A.D., Novosad, V. (eds) Advances in Thin Films, Nanostructured Materials, and Coatings. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-6133-3_35

Download citation

DOI: https://doi.org/10.1007/978-981-13-6133-3_35

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6132-6

Online ISBN: 978-981-13-6133-3

eBook Packages: EngineeringEngineering (R0)