Abstract

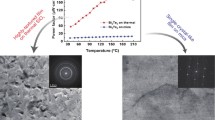

As it is well-known bulk high temperature superconductors are used in technological high power applications, as for instance, superconducting fault current limiters or current leads. Due to their intrinsic granularity and anisotropy issues, the superconducting properties of these materials are strongly determined by current percolation problems. This depends on several factors as the characteristics and properties of individual grains and the quality of the grain boundaries. Thermoelectric (TE) harvesting of wasted heat should play an important role in a sustainable future, due to its simplicity, scalability, and self-sustainability in all kind of applications: remote/attended or mobile/static ones. The development of oxide-based TE materials is important when considering that they are cheaper, and possess lower toxicity than the traditional ones. Moreover, oxides can be used at high temperatures without protecting atmospheres, opening new opportunities for energy recovering TE devices. On the other hand, it is desirable to tune up their TE performances before integration in practical applications. In consequence, in order to obtain bulk materials for the technological applications, it is necessary to develop fabrication techniques controlling the microstructure and shape materials. Recently, in order to fabricate the bulk high temperature superconductors and thermoelectrics with high physical properties, the laser technologies have been widely used. In these techniques, the anisotropy arising from the solidification process permits to aligning the grains within the textured bulk material. For this purpose, superconducting Bi2Sr2-xNaxCaCu2Ox and thermoelectric Bi2Sr2-xNaxCo2Ox samples were prepared and textured using the laser floating zone (LFZ) technique. Microstructural analysis of as-grown samples showed well oriented grains and a relatively high amount of secondary phases due to their incongruent melting. Annealing procedure has drastically decreased the number and amount of secondary phases. Moreover, Na-doping has further decreased the secondary phase content and improved grain alignment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Hsu AJ, Chang KS (2019) Physical, photochemical, and extended piezoelectric studies of orthorhombic ZnSnN2 nanocolumn arrays. Appl Surface Sci 470:19

Li JH, Xu SD, Deng Z, Wei LL, Yang ZP (2019) Photoluminescence and ferroelectric behaviors related to Sr/Ba ratioin Eu3+ doped (Srx Ba1-x)0.98Eu0.02Nb2O6 multifunctional tungsten bronze ceramics. J Alloys Compds 780:355

Bonura M, Barth C, Senatore C (2019) Electrical and thermo-physical properties of Ni-alloy Reinforced Bi-2223 Conductors. IEEE Trans Appl Supercond 29:6400205

Chen C, Delorme F, Schoenstein F, Zaghrioui M, Flahaut D, Allouche J, Giovannelli F (2019) Synthesis, sintering, and thermoelectric properties of Co1-x MxO (M = Na, 0 ≤ x ≤ 0.07; M = Ag, 0 ≤ x ≤ 0.05). J Eur Ceram Soc 39:346

Michel C, Hervieu M, Borel MM, Grandin A, Deslandes F, Provost J, Raveau B (1987) Superconductivity in the Bi-Sr-Cu-O system. Z Phys B 86:421

Maeda H, Tanaka Y, Fukutumi M, Asano T (1988) A new high-Tc oxide superconductor without a rare-earth element. Jpn J Appl Phys 27:209

Majewski P, Su HL, Quilitz M (1997) Relationships between the chemical composition and properties of the high-temperature superconductor Bi2+xSr2-yCa1+y Cu2O8+d. J Mater Sci 32:5137

Chen L, Zhang XY, Qin YJ, Chen HK, Shen Q, Xu Y, Ren L, Tang YJ (2019) Application and design of a resistive-type superconducting fault current limiter for efficient protection of a DC microgrid. IEEE Trans Appl Supercond 29:5600607

Heller R, Bau H, Nagel M, Rummel T (2019) Operation experience of the Wendelstein 7-X high-temperature superconductor current leads. IEEE Trans Appl Supercond 29:4200105

Sotelo A, Rasekh S, Amaveda H, Bosque P, Torres MA, Madre MA, Diez JC (2015) Textured Pb-doped Bi-2212 superconductors for current limiters. J Supercond Nov Magn 28:447

Costa FM, Ferreira NM, Rasekh S, Fernandes AJS, Torres MA, Madre MA, Diez JC, Sotelo A (2015) Very large superconducting currents induced by growth tailoring. Cryst Growth Des 15:2094

Nane O, Özçelik B, Amaveda H, Sotelo A, Madre MA (2016) Improvement of structural and superconducting properties of Bi-2212 textured rods by substituting sodium. Ceram Int 42:8473

Sotelo A, Ozcelik B, Amaveda H, Bruned A, Madre MA (2015) Fabrication and evolution of nanoprecursors to produce Bi(Pb)-2212/Ag textured superconducting Composites. Ceram Int 41:14276

Mahan G, Sales B, Sharp J (1997) Thermoelectric materials: new approaches to an old problem. J Phys Today 50:42

Bell LE (2008) Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321:1457

Naito H, Kohsaka Y, Cooke D, Arashi H (1996) Development of a solar receiver for a high-efficiency thermionic/thermoelectric conversion system. Sol Energy 58:191

Kim CM, Hwang YJ, Ryu YH (2002) Air conditioner for individual cooling/heating. US Patent US6393842, May

Elsheikh MH, Shnawah DA, Sabri MFM, Said SBM, Hassan MH, Renew MBABMM (2014) A review on thermoelectric renewable energy: principles parameters that affect their performance. Sust Energ Rev 30:337

Rowe DM (2006) Thermoelectrics handbook: macro to nano, 1st edn. CRC Press, Boca Raton

JM S, Alkorta J, JG S (2013) Mechanical properties of bismuth telluride (Bi2Te3) processed by high pressure torsion (HPT). Bol Soc Esp Ceram V 52:137–142

Wang HC, Bahk JH, Kang C, Hwang J, Kim K, Kim J, Burke P, Bowers JE, Gossard AC, Shakouri A, Kim W (2014) Right sizes of nano- and microstructures for high-performance and rigid bulk thermoelectric. P Natl Acad Sci USA 111:10949

Wang HC, Hwang J, Snedaker ML, Kim I-H, Kang C, Kim J, Stucky GD, Bowers J, Kim W (2015) High thermoelectric performance of a heterogeneous PbTe Nanocomposite. Chem Mater 27:944

Terasaki I, Sasago Y, Uchinokura K (1997) Large thermoelectric power in NaCo2O4 single crystals. Phys Rev B 56:12685

Abdellahi M, Bahmanpour M, Bahmanpour M (2015) Modeling Seebeck coefficient of Ca3-xMxCo4O9 (M=Sr, Pr, Ga, Ca, Ba, La, Ag) thermoelectric ceramics. Ceram Int 41:345

Li F, Li JF, Li JH, Yao FZ (2012) The effect of Cu substitution on microstructure and thermoelectric properties of LaCoO3 ceramics. Phys Chem Chem Phys 14:12213

Rubesova K, Hlasek T, Jakes V, Huber S, Hejtmanek J, Sedmidubsky D (2015) Effect of a powder compaction process on the thermoelectric properties of Bi2Sr2Co1.8Ox ceramics. J Eur Ceram Soc 35:525

Constantinescu G, Rasekh S, Torres MA, Madre MA, Diez JC, Sotelo A (2013) Enhancement of the high-temperature thermoelectric performance of Bi2Ba2Co2Ox ceramics. Scr Mater 68:75

Wang H, Wang CL (2013) Thermoelectric properties of Yb-doped La0.1 Sr0.9 TiO3 ceramics at high temperature. Ceram Int 39:941

Zhu YH, Su WB, Liu J, Zhou YC, Li J, Zhang X, Du Y, Wang CL (2015) Effects of Dy and Yb co-doping on thermoelectric properties of CaMnO3 ceramics. Ceram Int 41:1535

Itahara H, Xia C, Sugiyama J, Tani T (2004) Fabrication of textured thermoelectric layered cobaltites with various rock salt-type layers by using β-Co(OH)2 platelets as reactive templates. J Mater Chem 14:61

Özçelik B, Özkurt B, Yakinci ME, Sotelo A, Madre MA (2013) Relationship between annealing time and magnetic properties in Bi-2212 textured composites. J Supercond Nov Magn 26:873

Özçelik B, Nane O, Sotelo A, Madre MA (2016) Effect of Yttrium substitution on superconductivity in Bi-2212 textured rods prepared by a LFZ technique. Ceram Int 42:3418

Angurel LA, Díez JC, de la Fuente GF, Gimeno F, Lera F, López-Gascón C, Martínez E, Mora M, Navarro R, Sotelo A, Andrés N, Recuero S, Arroyo MP (2006) Laser technologies applied to the fabrication and characterization of bulk Bi-2212 superconducting materials for power applications. Phys Stat Sol A 203:2931

Sotelo A, Mora M, Madre MA, Amaveda H, Diez JC, Angurel LA, Mayoral MC (2006) Study of the variation of the E-I curves in the superconducting to normal transition of Bi-2212 textured ceramics by Pb addition. Bol Soc Esp Ceram 45:228

Özçelik B, Gürsul M, Sotelo A, Madre MA (2014) Effect of K substitution on structural, electrical and magnetic properties of Bi-2212 system. J Mater Sci Mater Electron 25:4476

Eisaki H, Kaneko N, Feng DL, Damascelli A, Mang PK, Shen KM, Shen ZX, Greven M (2004) Effect of chemical inhomogeneity in bismuth-based copper oxide superconductors. Phys Rev B 69:064512

Özkurt B, Ekicibil A, Ali Aksan M, Özçelik B, Yakıncı ME, Kiymaç K (2007) Structural and Physical Properties of Nd substituted bismuth cuprates Bi1.7Pb0.3-x NdxSr2Ca3Cu4O12+y. J Low Temp Phys 149:105

Bean CP (1962) Magnetization of hard superconductors. Phys Rev Lett 8:250

Sotelo A, Torres MA, Constantinescu G, Rasekh S, Diez JC, Madre MA (2012) Effect of Ag addition on the mechanical and thermoelectric performances of annealed Bi2Sr2Co1.8Ox textured ceramics. J Eur Ceram Soc 32:3745

Mercurio D, Champarnaud-Mesjard JC, Frit B, Conflant P, Boivin JC, Vogt T (1994) Thermal evolution of the crystal structure of the rhombohedral Bi0.75Sr0.25 O1.375 phase: a single crystal neutron diffraction study. J Solid State Chem 112(1):1–8

Costa FM, Ferreira NM, Rasekh S, Fernandes AJS, Torres MA, Madre MA, Diez JC, Sotelo A (2015) Very large superconducting currents induced by growth tailoring. Cryst Growth Des 15:2094

Rasekh S, Ferreira NM, Costa FM, Constantinescu G, Madre MA, Torres MA, Diez JC, Sotelo A (2014) Development of a new thermoelectric Bi2Ca2Co1.7Ox + Ca3Co4O9 composite. Scr Mater 80:1

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature B.V.

About this paper

Cite this paper

Özçelik, B., Çetin, G., Gürsul, M., Torres, M.A., Madre, M.A., Sotelo, A. (2020). Processing of Superconducting and Thermoelectric Bulk Materials Via Laser Technologies. In: Sidorenko, A., Hahn, H. (eds) Functional Nanostructures and Sensors for CBRN Defence and Environmental Safety and Security. NATO Science for Peace and Security Series C: Environmental Security. Springer, Dordrecht. https://doi.org/10.1007/978-94-024-1909-2_21

Download citation

DOI: https://doi.org/10.1007/978-94-024-1909-2_21

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-024-1908-5

Online ISBN: 978-94-024-1909-2

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)