Abstract

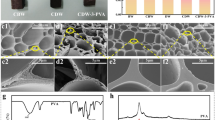

This chapter explores recent work related to thermochemical modification of low-value woody biomass to produce high-value products for use in bioenergy and biofuel applications. Through thermochemical modification (i.e., pretreatment), woody biomass can be transformed into materials that have higher calorific values and improved electrical properties. In this chapter, advancements in research related to torrefaction and carbonization (i.e., pyrolysis) are discussed, along with the development of densified torrefied pellets and carbon materials. Torrefaction of woody biomass is a less severe thermochemical treatment that results in higher-value materials that can be used in energy applications as a substitute for coal and as a filler material for composites. To advance the use of torrefied woody biomass as a coal replacement fuel, densification technology is a key for improving storage and transportation. This chapter explores some key processing variables and their relationship to pellet quality. In addition, the relative carbon content of woody biomass is increased through pyrolysis. These carbonized materials can be used for fuel cells, energy storage, and as a filler and potential reinforcement in a variety of composite materials. During pyrolysis of wood, the porosity of the resulting material increases. In general, porous carbon materials are classified as microporous (<2 nm), mesoporous (2–50 nm), and macroporous (>50 nm) based on their pore diameters. This chapter focuses on research related to mesoporous carbon that has the ability to provide fast mass transport of molecules and large specific surface areas. These two properties are essential in many advanced energy storage and conversion applications.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

ASABE Standards (2011) ANSI/ASABE S593.1: Terminology and definitions for biomass production, harvesting and collection, storage, processing, conversion and utilization. American Society for Agricultural & Biological Engineers, St. Joseph, MI

Baileys RT, Blankenhorn PR (1982) Calorific and porosity development in carbonized wood. Wood Sci 15(1):19–28

Bacon R, Tang MM (1964) Carbonization of cellulose fibers-II Physical property study. Carbon 2:221–225

Beall FC (1969) Thermogravimeteric analysis of wood lignin and hemicellulose. Wood Fiber Sci 1:215–226

Beall FC (1971) Differential calometric analysis of wood and wood components. Wood Sci Technol 5:159–175

Beall FC, Eickner HW (1970) Thermal degradation of wood components: A review of the literature. U.S. Department of Agriculture Forest Service. Available at http://www.fpl.fs.fed.us/documnts/fplrp/fplrp130.pdf. Accessed 20 Aug 2014

Bergman PCA (2005) Combined torrefaction and pelletisation: the TOP process (ECN-C–05-073). Energy Research Centre of the Netherlands. http://www.ecn.nl/docs/library/report/2005/c05073.pdf. Accessed 20 Aug 2014

Blankenhorn PR, Jenkins GM, Kline DE (1972) Dynamic mechanical properties and microstructure of some carbonized hardwoods. Wood Fiber Sci 4(3):212–224

Blankenhorn PR, Barnes DP, Kline DE (1978) Porosity and pore size distribution of black cherry carbonized in an inert atmosphere. Wood Science 11(1):23–29

Braun J, Holtman KM, Kadla JF (2005) Lignin-based carbon fibers: oxidative thermostabilization of kraft lignin. Carbon 43:385–394

Byrne CE, Nagle DC (1997a) Carbonization of wood for advanced materials applications. Carbon 35(2):259–266

Byrne CE, Nagle DC (1997b) Carbonized wood monoliths-characterization. Carbon 35(2):267–273

Edwards IAS (1989) Structure in carbon and carbon forms. In: Marsh H (ed) Introduction to carbon science. Butterworth and Co., London, pp 2–31

García-Maraver A, Popov V, Zamorano M (2011) A review of European standards for pellet quality. Renew Energy 36:3537–3540

Greil P, Lifka T, Kaindl A (1998) Biomorphic cellular silicon carbid ceramics from wood: I. Processing and microstructure. J Eur Ceram Soc 18:1961–1973

Inagaki M (2000) New carbon: control of structure and functions. Elsevier, Amsterdam and New York

Iniesta E, Sanchez F, Garcia AN, Marcilla A (2001) Influence of the holding temperature of the first heating step in a two-heating step carbonization process on the properties of chars and activated carbons from almond shells. J Anal Appl Pyrol 58–59:967–981

Jin H, Wang X, Gu Z, Polin J (2013) Carbon materials from high ash biochar for supercapacitor and improvement of capacitance with HNO3 surface oxidation. J Power Sources 236:285–292

Kaliyan N, Morey RV (2009) Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 33:337–359

Kercher AK, Nagle DC (2003) Microstructural evolution during charcoal carbonization by X-ray diffraction analysis. Carbon 41:15–27

Kinoshita K (1988) Carbon, electrochemical and physicochemical properties. Wiley & Sons Inc, London

Kollmann FFP, Sachs IB (1967) The effects of elevated temperature on certain wood cells. Wood Sci Technol 1:14–25

Kumar M, Verma BB, Gupta RC (1999) Mechanical properties of acacia and eucalyptus wood chars. Energy Sources 21:675–685

Li H, Liu X, Legros R, Bi XT, Lim CJ, Sokhansanj S (2012) Pelletization of torrefied sawdust and properties of torrefied pellets. Appl Energy 93:680–685

Li X, Han C, Chen X, Shi C (2010) Preparation and performance of straw based activated carbon for supercapacitor in non-aqueous electrolytes. Microporous Mesoporous Mater 131:303–309

Li X, Wei W (2013) Supercapacitors based on nanostructured carbon. Nano Energy 2:159–173

Mani S, Tabil LG, Sokhansanj S (2006) Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 30:648–654

Marsh H (1989) Introduction to carbon science. Butterworth & Co., Ltd, London, Boston, Singapore, Sydney, Toronto, Wellington

McGinnes J, Kandeel SA, Szopa PS (1971) Some structural changes observed in the transformation of wood into charcoal. Wood Fiber Sci 3(2):77–83

Moore GR, Blankenhorn PR, Beall FC (1974) Some physical properties of birch carbonized in a nitrogen atmosphere. Wood Fiber Sci 6(3):193–199

Nielsen PKN, Gardner DJ, Poulsen T, Felby C (2009) Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fiber Sci 41(4):414–425

Nishimiya K, Hata T, Kikuchi H (2004) Effect of aluminum compound addition on graphitization of wood charcoal by direct electric pulse heating method. J Wood Sci 50:177–181

Nishimiya K, Hata T, Imamura Y, Ishihara S (1998) Analysis of chemical structure of wood charcoal by X-ray photoelectron spectroscopy. J Wood Sci 44:56–61

Panshin AJ, deZeeuw C (1964) Textbook of wood technology, 3rd edn. McGraw-Hill Book Company, New York, St. Louis, San Francisco, Dusseldorf, London, Mexico, Panama, Sydney, Toronto

Paris O, Zollfrank C (2005) Decomposition and carbonisation of wood biopolymers—a microstructural study of softwood pyrolysis. Carbon 43:53–66

PFI (2018) Pellet Fuels Institute (PFI) standard specifications for residential/commercial densified fuel. Pellet Fuels Institute, Seattle, WA

Pintor M, Jean-Marius C, Jeanne-Rose V, Taberna P, Simon P, Gamby J, Gadiou R, Gaspard S (2013) Preparation of activated carbon from Turbinaria Turbinata seaweeds and its use as supercapacitor electrode materials. C R Chim 16:73–79

Plaisantin H, Pailler R, Guette A (2001) Conversion of cellulosic fibres into carbon fibers: a study of the mechanical properties and correlation with chemical structure. Compos Sci Technol 61:2063–2068

Prins M, Ptasinski K, Janssen FJJG (2006) Torrefaction of wood: Part 1. Weight loss kinetics. J Anal Appl Pyrolysis 77:28–34

Ramasamy E, Chun J, Lee J (2010) Soft-template synthesized ordered mesoporous carbon counter electrodes for dye-sensitized solar cells. Carbon 48:4556–4577

Rhen C, Gref R, Sjostrom M, Wasterlund I (2005) Effects of raw material moisture content, densification pressure and temperature on some properties of Norway spruce pellets. Fuel Process Technol 87:11–16

Setton R, Bernier P, Lefrant S (2002) Carbon molecules and materials. Taylor & Francis Inc., London and New York

Shang L, Ahrenfeldt J, Holm J, Sanadi A, Barsberg S, Thomsen T, Stelte W, Henriksen U (2012) Changes of chemical and mechanical behavior of torrefied wheat straw. Biomass Bioenergy 40:63–70

Shindo A, Nakanishi Y, Soma I (1969) Carbon fibers from cellulose fibers. In: Preston J (ed) Applied polymer symposia: high temperature resistant fibers from organic polymers. 156th meeting of the American Chemical Society, 9–11 Sept 1968, Atlantic City, vol 9. Interscience, New York, pp 271–284

Simon P, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7:845–854

Slocum DH, McGinnes JEA, Beall FC (1978) Charcoal yield, shrinkage, and density changes during carbonization of oak and hickory woods. Wood Sci 11(1):42–47

Stelte W, Nielsen N, Hansen H, Dahl J, Shang L, Sanadi A (2013) Pelletizing properties of torrefied wheat straw. Biomass Bioenergy 49:214–221

Tang MM, Bacon R (1964) Carbonization of cellulose fibers—I. Low temperature pyrolysis. Carbon 2:211–220

Telmo C, Lousada J (2011) Heating values of wood pellets from different species. Biomass Bioenergy 35:2634–2639

Wang T (2014) Compaction behavior, mechanical properties, and moisture resistance of torrefied and non-torrefied biomass pellets. Thesis, West Virginia University

Warren BE (1941) X-ray diffraction in random layer lattices. Phys Rev 59(9):693–698

Xie X, Goodell B, Daniel G, Qian Y, Jellison J, Peterson M (2009a) Carbonization of wood and nanostructures formed from the cell wall. Int Biodeterior Biodegradation 63:933–935

Xie X, Goodell B, Zhang D, Nagle D, Qian Y, Peterson M, Jellison J (2009b) Characterization of carbons derived from cellulose and lignin and their oxidative behavior. Biores Technol 100:1797–1802

Xie X, Goodell B, Qian Y, Peterson M, Jellison J (2008a) Significance of the heating rate on the physical properties of carbonized maple wood. Holzforschung 62:591–596

Xie X, Goodell B, Qian Y, Daniel G, Peterson M, Jellison J (2008b) Carbon nanotubes produced from natural cellulosic materials. J Nanosci Nanotechnol 8:2472–2474

Zeriouh A, Belkbir L (1995) Thermal decomposition of a Moroccan wood under a nitrogen atmosphere. Thermochim Acta 258(1995):243–248

Zondlo J, Velez M (2007) Development of surface area and pore structure for activation of anthracite coal. Fuel Process Technol 88:369–374

Zeckler GA, Schoberl T, Paris O (2006) Mechanical properties of pyrolysed wood: a nanoindentation study. Phil. Mag. 86:1373–1386

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Critical Thinking Questions

Critical Thinking Questions

-

1.

Pelleting and briquetting techniques have been used to densify woody biomass for many decades in the USA. Are there newer and less energy-intensive processes that may be adapted for densifying woody biomass?

-

2.

Uses of torrefied woody biomass have primarily been limited to energy-related applications as a substitute for coal. Given the inherent properties of torrefied wood material, what other potential value-added applications could exist for torrefied biomass?

-

3.

What role do wood pellets and carbonized materials play in the context of bioenergy and bioproduct development under a systems thinking approach?

-

4.

Could woody biomass-derived carbon materials be made strong enough for structural applications?

-

5.

What are the factors that affect the physical and chemical properties of the final products during thermochemical treatment of woody biomass?

Glossary

- Bulk density

-

“Mass per unit volume occupied by a large quantity of particulate material” (ASABE Standards 2011).

- Carbonization

-

“A process of formation of material with increasing carbon content from an organic material, usually by pyrolysis, ending up with almost pure carbon residue at temperature up to about 1600 K” (Marsh 1989).

- Cellulose

-

Linear long-chain polymer component, (C6H10O5)n, that is the primary material of the cell wall of wood and plant material.

- Cellulose microfibril

-

“A bundle of cellulose polymer chains and associated polysaccharides of other types that are united at some regions in highly ordered crystalline lattices known as crystallites and are less highly ordered in the zones between the crystallites (amorphous regions); it is the smallest natural unit of cell wall structure that can be distinguished with an electron microscope” (Panshin and deZeeuw 1964).

- Compaction energy

-

Energy required to compact wood particles or fibers to a specific final volume or density.

- Densification

-

“Process of increasing bulk density or energy content of biomass to improve handling, storage and transportation” (ASABE Standards 2011).

- Hemicellulose

-

Lower molecular weight, generally branched-chain polysaccharide component found in wood and plant material.

- Higher heat value

-

“The full energy content of a fuel. It is the amount of heat produced when a liquid fuel or oven dried solid fuel is fully combusted, all of the products of combustion are cooled to 25 °C (77 °F) and the water vapor formed during combustion is condensed into liquid water” (ASABE Standards 2011).

- Highly ordered mesoporous carbon

-

A porous carbon with very uniform pore size between 2 and 50 nm

- Hot water extraction

-

Process of using hot water (120–240 °C) or steam to extract hemicellulose in wood.

- Lignin

-

High molecular weight component based on phenylpropane units that is found in the cell wall and between cells in wood and plant material and acts primarily as a binding agent.

- Lower heat value

-

“Net heat released from the combustion of oven dry solid fuel after reducing the HHV by the heat of vaporization of the water generated by combustion of the hydrogen in the fuel. Each gram of hydrogen produces 9 grams of water” (ASABE Standards 2011).

- Macroporous carbon

-

A porous carbon material that has a major part of its porosity in pores of larger than 50 nm width.

- Mesoporous carbon

-

A porous carbon material that has a major part of its porosity in pores of width between 2 and 50 nm.

- Pellet

-

A densified or compacted product formed from particles or fibers.

- Pellet durability

-

A quality control measure that determines an index value of how well wood pellets hold up to feeding and handling.

- Pellet hardness

-

A quality control measure that determines the amount of force required to break a wood-type pellet.

- Pyrolysis

-

The chemical decomposition of a substance brought about by heat.

- Thermochemical

-

Heat-associated chemical and physical phenomena.

- Torrefaction

-

“A pretreatment method where biomass is subjected to moderate heating (200–300 °C) in a low oxygen environment” (ASABE Standards 2011).

- Torrefied biomass

-

Product resulting from the torrefaction of wood and other plant-type materials.

- Woody biomass

-

Any part of a tree and woody plants grown in forests and on other land that are generally classified as by-products from other harvesting operations.

Rights and permissions

Copyright information

© 2020 Springer Nature India Private Limited

About this chapter

Cite this chapter

DeVallance, D.B., Xie, X., Wang, T., Wang, J. (2020). Advancements in Thermochemical Modification of Wood for Bioenergy and Biomaterial Applications. In: Mitra, M., Nagchaudhuri, A. (eds) Practices and Perspectives in Sustainable Bioenergy. Green Energy and Technology. Springer, New Delhi. https://doi.org/10.1007/978-81-322-3965-9_10

Download citation

DOI: https://doi.org/10.1007/978-81-322-3965-9_10

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-3963-5

Online ISBN: 978-81-322-3965-9

eBook Packages: EnergyEnergy (R0)