Abstract

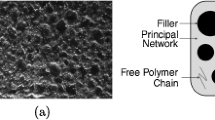

Thermoplastic melts and rubber compounds are viscoelastic fluids. They show a complex flow behavior, which is influenced by various factors such as polymer type, molar mass distribution, recipe, filler-filler network and in some cases wall slippage. Most of the state-of-the-art simulation software packages use viscous material models for the calculation of the flow field as well as pressure and temperature distribution, neglecting the viscoelastic nature of polymers. This simplification may lead to an underestimated pressure demand in injection molding simulation.

This contribution presents how to correctly measure viscosity data (shear and extensional viscosity) for thermoplastics and rubber compounds taking into account the pressure dependency of the viscosity and the influence of viscous dissipation in capillary rheometry at higher shear rates. Moreover, a guideline on how to best fit rheological data with the viscoelastic K-BKZ/Wagner model is outlined. Comparing CFD simulation results to experimental data, only the K-BKZ/Wagner model is able to correctly predict pressure losses of contraction flow dominated geometries. Examples will be given for NBR and PP-PNC.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Literatur

Fasching, M.: Robust processing in rubber injection molding using advanced simulation methods and material data. Dissertation, Montanuniversitaet Leoben (2015)

Mitsoulis, E.: 50 Years of the K-BKZ Constitutive Relation for Polymers. ISRN Polym. Sci. 1–22 (2013)

Ansari, M., Hatzikiriakos, S.G., Mitsoulis, E.: Slip effects in HDPE flows. J. Non-Newtonian Fluid Mech. (2011)

Ansari, M., Zisis, T., Hatzikiriakos, S.G., Mitsoulis, E.: Capillary flow of low-density polyethylene. Polym. Eng. Sci. 52, 649–662 (2012)

Konaganti, V.K., Derakhshandeh, M., Ebrahimi, M., Mitsoulis, E., Hatzikiriakos, S.G.: Non-isothermal extrudate swell. Phys. Fluids 28, 123101 (2016)

Mitsoulis, E.: Effect of Viscoelasticity in Fountain Flow of Polyethylene Melts. Int. Polym. Proc. 24, 439–451 (2009)

Mitsoulis, E., Battisti, M., Neunhäuserer, A., Perko, L., Friesenbichler, W., Ansari, M., Hatzikiriakos, S.G.: Flow behaviour of rubber in capillary and injection moulding dies. Rubber Compos. 46, 110–118 (2017)

Mitsoulis, E., Battisti, M., Neunhäuserer, A., Perko, L., Friesenbichler, W.: Flow behavior of PP-polymer nanocomposites in injection molding hyperbolical dies. Adv. Polym. Technol. 1–11 (2018)

Lucyshyn, T.: Simulation report for a thin-walled bushing for company PKT Praezisionskunststofftechnik Buertlmair Gesellschaft m.b.H. Institute of Polymer Processing, Montanuniversitaet Leoben (2016)

Perko, L., Fasching, M., Friesenbichler, W.: Model for the prediction of bulk temperature changes and pressure losses in rubber compounds flowing through conical dies: An engineering approach. Polym. Eng. Sci. 55, 701–709 (2014)

Cogswell, F.N.: Converging flow of polymer melts in extrusion dies. Polym. Eng. Sci. 12, 64–73 (1972)

Perko, L., Friesenbichler, W., Obendrauf, W., Buchebner, V., Chaloupka, G.: Elongational viscosity of rubber compounds and improving corresponding models. Adv. Prod. Eng. Manag. 8, 126–133 (2013)

Binding, D.: An approximate analysis for contraction and converging flows. J. Non-Newtonian Fluid Mech. 27, 173–189 (1988)

Sentmanat, M.L., Rheol, M.L.: Miniature universal testing platform: from extensional melt rheology to solid-state deformation behavior. Acta 43, 657 (2004)

ANSYS Inc.: ANSYS Polyflow User’s Guide: Release 18.2: Canonsburg, PA, USA (2017)

Wagner, M.H.: A constitutive analysis of uniaxial elongational flow data of low-density polyethylene melt. J. Non-Newtonian Fluid Mech. 4, 39–55 (1978)

Leblanc, J.: Rubber–filler interactions and rheological properties in filled compounds. Prog. Polym. Sci. 27, 627–687 (2002)

Payne, A.R.: The dynamic properties of carbon black-loaded natural rubber vulcanizates. Part I. J. Appl. Polym. Sci. 6, 57–63 (1962)

Friesenbichler, W., Berger, G., Fasching, M.: Simulation of Rubber Injection Molding – Challenges and Limitations. Conference Proceedings of the 7th bi-annual International Conference of Polymer & Molds Innovations (PMI). Gent 2016. pp. 179–183

Acknowledgements

This research work was supported by the Austrian Research Promotion Agency (FFG) as part of the “RubExject II” project (corresponding project number 855873) and the company partners SKF Sealing Solutions Austria GmbH, Judenburg, Austria, IB Steiner, Spielberg, Austria and ELMET Elastomere Produktions- und Dienstleistungs-GmbH, Oftering, Austria. The authors further thank company PKT Praezisions-kunststofftechnik Buertlmair Gesellschaft m.b.H. and Prof. T. Lucyshyn, Dr. Ivica Duretek, MSc Stephan Schuschnigg and Dr. Matthias Haselmann for their respective contributions.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer-Verlag GmbH Germany, part of Springer Nature

About this paper

Cite this paper

Friesenbichler, W., Stieger, S., Kerschbaumer, R., Berger-Weber, G., Neunhaeuserer, A., Mitsoulis, E. (2020). Viscoelastic Modelling of Polymer Melts and Rubber Compounds. In: Hopmann, C., Dahlmann, R. (eds) Advances in Polymer Processing 2020. Springer Vieweg, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-60809-8_22

Download citation

DOI: https://doi.org/10.1007/978-3-662-60809-8_22

Published:

Publisher Name: Springer Vieweg, Berlin, Heidelberg

Print ISBN: 978-3-662-60808-1

Online ISBN: 978-3-662-60809-8

eBook Packages: EngineeringEngineering (R0)