Abstract

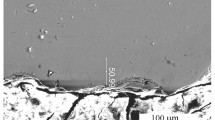

With the developing requirement of nature gas, the property needs of steel for pipe line are higher and higher, especially in strength and toughness. It is necessary to improve the steel grade in order to ensure economic demand and safety. However, with the rise of steel grade, the differences on properties in different orientations (anisotropic behaviors) become more and more obvious after the process of hot rolling, which may affect the prediction of fracture for the pipes seriously (Thinking of isotropic mechanical properties for material in traditional predict way). In order to get the reason for anisotropic mechanics, a series of tests are carried out for high grade steel pipes, including not only mechanical properties but also microstructures. Result indicates that there are obviously anisotropic behaviors for high grade steel pipes in two orientations (rolling orientation and transverse orientation). Strength is better in T orientation because Rm is higher and Rt 0.5 rises more in T orientation, and toughness is better in L orientation because of the higher Akv and SA in L orientation under a same temperature. Banded structures are formed in T orientation, and the spatial distribution of inclusion and precipitated phases are different in T, L and S orientation. The anisotropic arrangement for the matrix in space (banded structures), which is formed after the process of hot rolling, may affect the mechanical properties in different orientation. Moreover, the elasticity modulus of particles is different from the elasticity modulus of matrix, deformation between particles and matrix may cause stress concentration, and damage forms in this place. Because of the different distribution of particles in space, the level of damage is anisotropic in different orientations, and the anisotropic mechanical properties occur finally. Therefore, the anisotropic mechanical properties are determined by the anisotropic microstructures, both the anisotropic of matrix and the anisotropic of particles are included.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

Reference

T.B. Cox, J. R. Low, Met Trans, 5 (1974), 1457–1470.

F. M. Beremin, Three-dimensional constitutive relations of damage and fracture (Oxford: Pergamon Press, 1981).

S. Shima, M. Oyane. Int J Mech Sci, 18 (1976), 285–291.

E. Parteder, H. Riedel, D.Z. Sun, Int J Refrac Met Hard Mater, 20 (2002), 287–293.

A. A. Benzerga, J. Besson, A. Pineau, “Anisotropic ductile fracture Part I: experiments”, Acta Materialia, 52(2004), 4623–4638.

A. A. Benzerga, J. Besson, A. Pineau. “Anisotropic ductile fracture Part II: theory”, Acta Materialia, 52 (2004), 4639–4650.

G. Mirone, D. Corallo, “Stress–strain and ductile fracture characterization of an X100 anisotropic steel: Experiments and modelling,” Engineering Fracture Mechanics, 102 (2013), 119–145.

D. C. Drucker, W. Prager, “Soil mechanics and plastic analysis for limit design,” Q Appl Math, 10 (1952), 157–65.

D. Bigoni, A. Piccolroaz, “Yield criteria for quasi brittle and frictional materials,” Int J Solids Struct, 41 (2004), 2855–2878.

Y. Bai, T. Wierzbicki, “A new model of metal plasticity and fracture with pressure and Lode dependence,” Int J Plast, 24 (2007), 1071–1096.

F. Barlat, D.J. Lege and J. C. Brem, “A six-component yield function for anisotropic materials,” Int J Plast, 7 (1991), 693–712.

R. Hill, “User-friendly theory of orthotropic plasticity in sheet metals,” Int J Mech Sci, 35(1993), 19–25.

F. Bron, J. Besson. “A yield function for anisotropic materials: application to aluminum alloys,” Int J Plast, 20 (2004), 937–63.

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 2014 TMS

About this paper

Cite this paper

Kun, Y., Chunyong, H., Lingkang, J., Yang, L., Jiming, Z., Qiurong, M. (2014). Characterization of Anisotropic Behavior for High Grade Pipes. In: Energy Materials 2014. Springer, Cham. https://doi.org/10.1007/978-3-319-48765-6_93

Download citation

DOI: https://doi.org/10.1007/978-3-319-48765-6_93

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48598-0

Online ISBN: 978-3-319-48765-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)