Abstract

The development of the global container fleet has followed a clear trend towards ever larger ships over the last 25 years. Particularly striking in this regard is the rise of the dimensionally largest ships, the so-called Ultra Large Container Vessels or ULCVs that can no longer pass through the new locks of the Panama Canal. While recent events such as the six-day blockade of the Suez Canal by the Ever Given have revealed environmental and safety risks of deploying these vessels, even the scheduled and smooth operation generates a whole range of challenges, impacts and costs that come at the expense of external stakeholders. The article aims at identifying these external effects as related to seaport systems as well as environmental considerations by consolidating insights from the scientific and professional discourse.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

1 Introduction

Over the past 25 years, the slot capacity of the global container ship fleet has increased continuously as a consequence of a steadily growing number of vessels that have become larger and larger on average. Especially in the years prior to the global financial and economic crisis of 2008/2009, annual increases in total capacity were almost continuously above 10%. During this time, the number of container ships also increased sharply, at times at double-digit annual rates. Since 2010, it can be observed that the number of container ships is only increasing rather slowly, while the average ship size in terms of nominal capacity continues to rise almost linearly. Particularly striking in this regard is the rise of the dimensionally largest ships, the so-called Ultra Large Container Vessels or ULCVs. While this size segment consisted of only eight Maersk E-class vessels with a total capacity of approximately 143,000 TEU before 2012, more than 160 ULCVs with a total capacity of over 3.2 million TEU were already in service at the beginning of April 2021 (CRSL 2021b).

By using ever larger vessels, liner shipping companies are taking advantage of the so-called economies of scale, which have enabled to continuously reduce costs per TEU transported and have given the ULCV its raison d’être (Ge et al. 2019). Any negative effects are still dealt with rather peripherally, and so it is primarily the cost effects of operating ULCVs from an isolated shipping company perspective that dominate the discussion. The fact that the operation of ULCVs also involves costs and impacts on ‘external’ systems is often overlooked. Critical events such as the accidents of the CSCL Indian Ocean in 2016, the CSCL Jupiter in 2017, the ONE Milano Bridge in 2020 or the current six-day blockade of the Suez Canal by Ever Given clearly show that this is necessary. However, it is not only exceptional circumstances, such as accidents caused by human or technical failures that have a negative impact on areas outside the liner shipping companies. Even the scheduled and smooth operation of such vessels generates a whole range of challenges, impacts and costs that come at the expense of other stakeholders or the general public, often referred to as diseconomies of scale (Stopford 2009). Likewise, there are also positive and often misappropriated effects of ULCVs that are not directly related to operational profitability.

This article aims at identifying these external effects as related to seaport systems as well as environmental considerations by consolidating insights from the scientific and professional discourse. In order to illustrate the future importance of ULCV within the shipping market, the development of the container ship fleet over the last 25 years is first outlined and the increasing capacity share of the largest units elaborated afterwards. Since there currently exists no uniform understanding of which determinants make a large container ship a ULCV, Chapter “Autonomous Control of Logistics Processes: A Retrospective” of this article provides a clear definition. Furthermore, estimates on future vessel size developments will be presented as well. Chapter “Explorable Uncertainty Meets Decision-Making in Logistics” deals with the implications that increasing vessel sizes have for seaport systems. This includes not only necessary adaptions of port infra- and superstructures but also operational performance requirements that shipping lines impose on terminal operators. As operational constraints of ULCVs influence port choice decisions of shipping companies, ongoing and future effects on port network structures are discussed as well. In Chapter “Complex Networks in Manufacturing and Logistics: A Retrospect” the most relevant environmental impacts of ULCVs are outlined. After an outline of the different impacts is given, possible benefits that ULCVs have over smaller vessel units are considered. Subsequently, the improvements of ULCVs energy efficiency are discussed in the context of emission regulations. The section concludes with the environmental impacts of dredging operations, which are conducted to accommodate ever larger vessels.

2 The Rise of ULCVs

2.1 Towards Gigantism and Segmentation in Container Shipping

While the number of ships within the global container fleet has increased marginally by 9% since 2011 (from 4933 in April 2011 to 5450 units in April 2021), capacity in terms of container slots has grown by more than 65% (from 14.4 to 23.8 million TEU) (see Fig. 1). This relatively high capacity growth compared to the small number of new buildings indicates that container ships are becoming larger on average. In fact, the average nominal capacity of a container vessel increased by a total of 185% between 1996 and 2021, respectively, from 1524 to 4351 TEU per ship (CRSL 2021b). The strongest driver of this constant growth in size were and are the economies of scale that ultimately led shipping lines with larger units to the deployment of ULCVs (Ge et al. 2019). While economies of scale are very distinct for comparably smaller units, however, the positive effect diminishes with increasing size and so the question to which ship size further capacity growth is still worthwhile has been the subject of controversial debate for many years (Ge et al. 2019). Stopford, for example, argues that economies of scale below 4000 TEU are more evident than above (Stopford 2009). With 7500 TEU Sys gives a somewhat higher threshold than Stopford, but also states that economies of scale for the shipping lines decrease sharply as units become larger (Sys et al. 2008). Recent studies show that under favourable market conditions, with a slot utilization of over 90% and high freight rates, 25,000 TEU vessels can still achieve significant advantages over smaller units with capacities of 18,000 or 20,000 TEU (Ge et al. 2019). It is therefore hardly surprising that order activities for container ships with capacities of more than 23,000 TEU have picked up strongly since the fourth quarter of 2020, as charter rates for container ships have only known one direction since the multi-year low in June 2020, and that is up (CRSL 2021a). As of the beginning of April 2021, out of the total of around 589,000 TEU in the order book in this size-class, which are to be delivered in 2023 (see Fig. 2), nearly 474,000 TEU have been ordered since October 2020 (CRSL 2021a).

Development of world container fleet according to the number of ships, total nominal fleet capacity and average nominal capacity per ship (CRSL 2021b)

Containership deliveries according to nominal capacity as of 04th April 2021 (in 1000 TEU) (CRSL 2021b)

Until around 2011, the nominal total capacity of the global container ship fleet was distributed rather homogeneously among various ship sizes up to a maximum of 14,999 TEU, with the deliveries of Maersk E-class ships in the years 2006 to 2008 standing out clearly (see Fig. 2). Since 2012, a segmentation into merely three size segments is observable. The first segment consists of smaller units up to 5999 TEU, with Feeder- and Feeder-Max-vessels making up the major share. The second segment includes large units with nominal capacities between 11,000 and over 16,000 TEU, which are still able to pass the Neo-Panamax locks due to their dimensions. In this segment, it can be observed, in particular with regard to the units in the current order book, that ships over 15,000 TEU represent the largest subgroup in terms of capacity. Since 2020, the third segment has consisted exclusively of vessels with a nominal capacity of over 23,000 TEU. This means that since 2020, no vessel with a nominal capacity between 17,000 and 22,999 TEU has been delivered or ordered, so that it can be said with a fair degree of certainty that future fleet growth will take place exclusively above 23,000 TEU. If all units in the order book are delivered as planned by 2023, this size segment will be more than double by then (CRSL 2021b).

2.2 Too Big for the Panama Canal

The term Ultra Large Container Vessel (ULCV) emerged in the early 2000s to describe model designs that were beyond the largest container ships of the time in terms of dimensions and capacity. At that time, when the so-called Maersk C-class (LOAFootnote 1 345 m, Beam 42.8 m, Draught 14.5 m, Capacity 8650 TEU) was the largest container ship ever built (CRSL 2021a), there were concepts for ships with up to 12,500 TEU where the term ULCV or Ultra Large Container Ship (ULCS) was already in use (van Ham 2005, p. 89). Albeit ships with more than 18,000 TEU seemed feasible from a shipbuilding point of view (Wijnolst et al. 1999, p. 74), it was assumed that the limitations, in particular port limitations, associated with their size would prevent widespread acceptance of such vessels (van Ham 2005). The units of up to 24,000 TEU that are in service today falsified this assumption.

To date, there is no clear and uniform definition of when a container ship is considered a ULCV and the term is usually used for the largest existing ships at the time. In general, it is common practice to divide container ships into certain classes based on their nominal slot capacity in TEU. The various relevant thresholds for ULCVs are, for example, 14,500 TEU (Sahoo 2021), 15,000 TEU (Lian et al. 2019) or even 18,000 TEU (Heaney et al. 2020). In some cases, the size restrictions of the new locks of the Panama Canal are cited as relevant differentiator for vessels in addition to the nominal capacity (Heaney et al. 2020; Sahoo 2021). Additionally, the terms MGX-23 and MGX-24 (pronounced Megamax) are used for ships with a width of 23 and 24 container rows, respectively, with nominal capacities of around 18,000 to almost 24,000 TEU (Alphaliner 2017). Because of this multitude of different definitions, it is important to accurately define the term ULCV for the purposes of this article.

Looking at the growth in ship size over the past decades (see Fig. 3), it is noticeable that the increases of the nominal capacity between 1996 and 2005 were almost exclusively achieved by longer ships with a slightly increased draught, while the beam stagnated at 42.8 m. The commissioning of the Maersk E-class in 2006 opened a new chapter in ship size growth. With a LOA of almost 400 m, a beam of over 56 m and a draught of up to 15.5 m, these ships were significantly larger than container ships built up to that time. The capacity is given by the classification society American Bureau of Shipping as 11,000 TEU (American Bureau of Shipping 2021), while other sources state the capacity as 15,000 (Haas 2016). This discrepancy can be explained by the use of different calculation methods to determine the capacity. While the classification society has assumed a pre-specified weight/TEU condition (here 14 tonnes/TEU), a so-called homogeneous loading condition, the other values describe the nominal capacity, that means the maximum allowable number of containers, in terms of SOLAS navigational bridge visibility requirements (Koutroukis et al. 2013; Haas 2016; IMO 2020b). By increasing the height of the deckhouse and the lashing bridges, the nominal capacity of the Maersk E-class was increased to 17,816 TEU in 2018 (THB 2018; CRSL 2021b). The Maersk E-class was replaced by CMA CGMs Explorer-class as the largest container ship in terms of nominal capacity in 2012. An example for one of the vessels of this class is the CMA CGM Marco Polo. While the Explorer-class is shorter and narrower than the Maersk E-class, the maximum draught has been increased to 16 metres. In particular, the new twin-island design, i.e. the location of the bridge at the foreship section with the engine room located at semi-aft, resulted in improved visibility and has significantly increased nominal capacity. When applying the homogeneous calculation method with 14 tonnes/TEU, vessel operator CMA CGM indicates the capacity with 11,358 TEU, what is more or less equal to the capacity of the Maersk E-class.

Development of container ship sizes by nominal capacity, LOA and Beam, based on the largest ship in the respective year by nominal capacity (CRSL 2021b)

The next significant step since the Maersk E-class towards ships, which were actually and not only capacity-theoretically larger, was taken in 2013 with the Maersk Triple E-class. With a length of still approximately 400 m and a beam of 59 m these twin-island ships can accommodate 23 container rows and thus are a whole container row wider than the Maersk E-class (CRSL 2021b). With these ships, the era of slow steaming has also entered the design specs of the ULCV. A comparison of the Triple E-class’ engine performance with that of the Maersk A-class from 2003 shows that it is almost identical, with nearly twice the deadweight (CRSL 2021b). Because of their 23rd container row, the Maersk Triple E-class and other ships of comparable size are also called MGX-23 (Alphaliner 2017). From 2013 up to and including 2018, the dimensions of the largest container ships have remained virtually the same. While new nominal capacity records have been set every year, these are merely theoretical and range between 18,000 and 21,000 TEU. In 2017, the term MGX-24 emerged to refer to a new generation of containerships with an additional 24th container row that entered service in 2019 (Alphaliner 2017). While still around 400 m in length, these ships are more than 61 m wide, have a draught of up to 16.5 m and a nominal capacity of more than 23,000 TEU (CRSL 2021b).

Based on the above, it has been shown that looking at nominal capacity data as a sole determinant of ship size can be misleading. Instead, static parameters, i.e. length and beam of ships, must be included in the consideration. As presented in the following sections, the draught has significant effects on the seaport system but as a dynamic parameter it is not suitable for grouping purposes. In this article, ULCVs are defined as container ships that can no longer pass through the new locks of the Panama Canal due to their static dimensions of LOA and beam. This means that container ships with a LOA greater than 367.28 m and/or a beam greater than 51.25 m (Panama Canal Authority 2021) are regarded as ULCVs. Within the segment, in particular the increased beams for 23 container rows from 2013 and for 24 container rows from 2019 onwards represent significant development steps.

However, since almost all statistics on the container ship fleet are subdivided according to nominal capacity, an attempt is made to establish comparability here. In terms of capacity, currently almost all ships with a nominal capacity of over 15,000 TEU fall into the just mentioned definition of ULCVs in terms of dimensions. Of the 184 units in service with more than 15,000 TEU, only seven are still able to transit the Neo-Panamax locks of the Panama Canal (CRSL 2021b). These seven vessels entered service in 2019 and 2020 and have a nominal capacity between 15,052 and 16,010 TEU (CRSL 2021b). This again demonstrates the difficulty of assigning ship size classes based on nominal capacity. While all vessels with a nominal capacity above 15,000 TEU that were built until 2018 have dimensions that make transiting through the Panama Canal impossible, there are newer designs that push the theoretical capacity limit further up. The aforementioned 16,010 TEU nominal capacity currently represents the new capacity limit to Neo-Post-Panamax vessels and thus to ULCVs in the sense of this article. Ergo, while a TEU threshold of 15,000 TEU seems reasonable for the consideration of the fleet development until 2018, this threshold would have to be set higher from 2019 onwards. With the exception of three ships, all ships built after 2019 that no longer fit through the Panama Canal due to their dimensions have a nominal capacity of at least 19,000 TEU. In addition, the current order book does not show a single order in the capacity range between 16,010 and 23,000 TEU. Thus, from 2019 onwards, a capacity limit of 19,000 TEU would cover all ULCVs in the sense of this article, except three ships of the Maersk H-class with a nominal capacity of 15.226 TEU that cannot transit the Neo-Panamax locks due to their beam (CRSL 2021b). All ULCVs currently in service have been deployed on the main east-west trades between Europe and Far East (CRSL 2021b), and pushed medium-sized ships into other trade routes, where these ships in turn displace even smaller units. This phenomenon is known as the cascading effect (Cariou and Cheaitou 2014).

2.3 Where Do we Grow from Here: Bigger Vessels Yet to Come?

An answer to the question of where the growth in size in container shipping will lead can only be speculative at present. Malchow considers that construction of the first 30,000 TEU ships (nominal capacity) can start as early as 2025. Malchow bases his forecast on the exponential continuation of the development of the nominal slot capacity of the respective largest ships in terms of capacity since the end of the 1960s (Malchow 2017). The dimensions of these 30,000 TEU container ships are the subject of controversial debate. While Park et al. give the dimensions of these ships, determined by a regression analysis, as 453 m LOA, 72.0 m beam and up to 17.3 m draught (Park and Suh 2019), new forecasts are much more modest here. Thus, according to a recent publication by Alphaliner, the 30,000 TEU mark could be reached with dimensions of 425 m × 66.1 m, which would involve an extension of two 40’ bays compared to the MGX-24 ships and a widening to 26 rows. Until then, appropriate intermediate steps would be taken over length and width, for example by stretching the vessel to 425 m while adding only one extra row to 25 rows in total (Alphaliner 2021).

3 Implications for Seaport Systems

3.1 Necessity to Adapt to ULCV Requirements

As the example of the Panama Canal illustrates, the relationship between bottlenecks onshore and the developments in vessel sizes is one of reciprocal influences. This also holds true for seaport systems that provide the link between maritime and hinterland transportation (Carbone and Martino 2003) and thus ensure a transformation of mass to single transports (and vice versa) (Schönknecht 2009). While it can be argued that the ‘gigantism in containerships’ has been significantly stimulated by efficiency gains in container terminals over the last decades (Haralambides 2019), the rise of ULCVs has induced a number of challenges that seaports currently face. As will be shown in the following section, those challenges are not just apparent due to the sheer dimensions of those vessels but also due to the performance requirements that are connected with executing high-intensity port calls at maximum pace. Ultimately, the capabilities of port systems to adapt to current and future vessel sizes will most likely affect operational choices by shipping alliances and thus will have an impact on the structure of future port and transport networks.

3.2 Maritime Accessibility No Longer a Matter of Course

The dimensions of container vessels have taken a steep curve in the last 25 years. By making heavy investments, most ports have managed to adapt to these developments and thereby maintaining their ability to accommodate vessels nautically as well as serving them operationally at berth (Sys et al. 2008). However, in light of the recent and future generations of ULCVs, maritime accessibility is not a matter of course any longer and often not given at all or only under certain conditions (Notteboom 2016). From a nautical point of view, access to the port is constrained by the dimensions of the approach channel, which links ‘the berths of a port and the open sea’ (PIANC 2014) as well as turning basins and berths within the port. To safely navigate a vessel, sufficient space, air draughtFootnote 2 as well as under keel clearance needs to be guaranteed at all times (PIANC 2014). As outlined in the previous section, today’s ULCVs come with a maximum draught of 16.5 m, while the individual draught depends on the load situation of the vessel. A closer look on draught restrictions of selected container ports indicates that fully loaded ULCVs often already reach or exceed the set limits (Sys et al. 2008; Rodrigue 2021). Well-known examples include the Northern European ports of Antwerp, Bremerhaven and Hamburg, which are currently restricted to draughts of less than 16 m even at high tide (Hansestadt Bremisches Hafenamt 2021; Scheldecoördinatiecentrum Vlissingen 2021; Hamburg Port Authority 2018). The same situation can be observed in North America, e.g. in ports located at the Gulf of Mexico and several East Coast ports in the USA (Rodrigue 2021). As a result, water depth has become a major bottleneck for many ports in their quest to accept the largest container vessels.

By making use of tidal windows and specific speed and weather limits (Vantorre et al. 2014), some port and traffic authorities follow ‘access policies’ that allow for accommodation for ULCVs under strict conditions. Also, shipping companies may decide to reduce vessel draughts, e.g. by changing the port rotation sequence so that ports with restrictions will be called at a lower load factor (Merk et al. 2015; Det Norske Veritas AS 2013). However, all these organizational measures come with less flexibility and increased costs for shipping companies and thus make the transport less profitable (Sys et al. 2008). A common approach to improve the water depth conditions is to deepen and widen berthing areas, turning basins and approach channels through dredging. It involves ‘the operation of removing material from one part of the water environment and relocating it to another’ (European Dredging Association n.d.). However, in addition to high costs, physical and environmental limitations need to be considered in regard to dredging operations. The problem intensifies for ‘inside ports’ that face even more unfavourable conditions with respect to available space, natural water depths and thus costs and environmental impacts (Andrés and Piniella 2017). As various cases of the near past have illustrated, the increased dimensions of ULCVs ultimately make navigating and manoeuvring more difficult and allow for significantly less margin of error (Mallin and To 2016).

Further conditions to handle vessels alongside the berth include adaptions of quay structures as well as superstructure to carry out loading and unloading processes. This comprises quay structures and mooring systems that are dimensioned sufficiently to handle increased bollard pull forces of larger vessels (Mallin and To 2016; Stoschek et al. 2018; Soderberg 2017). Not just the added forces induced by the vessel itself put additional strain on quay structures, but also the weight and leverage of ship-to-shore (STS) cranes that allow processing all tiers and rows of the vessel (Park and Suh 2019). As shown in Sect. 2.2, vessels that fit with our definition of ULCVs come with a beam of 59–61.5 m and can carry 23–24 rows across and 10–11 tiers on deck. Thus, ULCVs induce special requirements on the cranes outreachFootnote 3 as well as on the maximum lifting height (Park and Suh 2019). Cranes that meet these demands are often referred to as ‘Super Post-Panamax’ (Čerin and Beškovnik 2020) or ‘Megamax’ cranes (Liebherr Group 2021). The largest STS cranes to date come with an outreach of 80 m, a lifting height of 54 m and allow for handling of 26 rows across (Hill 2020a, b). Thus, it can be expected that these cranes will be able to process future ULCV generations (see 2.3).

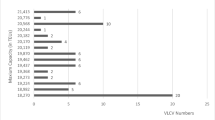

As shown in Fig. 4, the worldwide STS crane deliveries of the near past reflect the growth of vessel sizes. With respect to outreach for example, the share of new cranes that are able to serve 23+ rows and come with an outreach of 60.0 m and above went from of 38% in 2011 to 81% in 2017. The same trends can be observed for other parameters such as lifting height and lifting weight (PEMA 2018). The developments on the equipment market indicate that terminal operators are actually trying to cope with and prepare for increased vessel sizes by adapting their superstructure.

Global STS crane deliveries by outreach (2011–2017) (PEMA 2018)

3.3 Increased Pressure to Squeeze Berth Productivity

Assuming a slot utilization similar to smaller vessels, it becomes obvious that increased container capacities on ULCVs are likely to lead to a higher number of containers to be handled per port call, commonly referred to as the ‘call size’. Due to this, practical observations from experts as well as empirical studies show that ULCVs experience significantly longer port stay times compared to smaller units (Specht et al. 2020; JOC Group 2014).

Due to increased capital intensity of ULCVs paired with slow steaming strategies, non-productive port stay time endangers profitability of those services (Haralambides 2019; Lane and Moret 2014). As a result, carriers exert enormous pressure on terminal operators to increase handling efficiency and consequently reduce the duration of port calls. The predominant metric that allows for comparisons between ports and terminals is ‘gross berth productivity’, which compares the number of loading and unloading operations per call with the total port stay time (JOC Group 2014). In general there are two main components affecting the ‘operational’ part of berth productivity, being the speed and productivity of the cranes, usually quantified as moves per hour, and the number of cranes deployed on the vessel, also referred to as ‘crane intensity’ (Merk et al. 2015).

Even though increased outreach and lifting heights result in higher travel distances, it can be observed that crane manufacturers have managed to increase cycle speeds of Megamax cranes compared to older and smaller ones. Among other technological solutions, Megamax cranes usually allow to use twin-lift or even tandem-lift spreaders, which enable to transport two containers at the same time, i.e. up to 4 TEU in one move (Böse 2020). Besides the physical capabilities of the crane itself, the efficiency of quay-to-yard transportation systems, which need to guarantee a seamless flow of containers from and to the crane, is a prerequisite to maximize cycle speeds (Lane and Moret 2014). Crane density as the other setscrew needs to account for blocking and safety constraints between adjacent cranes as well as the layout of the respective ship (e.g. position of bays and bridges) and is therefore constrained for each type of vessel (Martin et al. 2015). Furthermore, different operational factors such as the availability of cranes and workforce, crane occupation on other vessels at berth or contractual commitments influence how many cranes can and will be deployed during a specific port call. As a result, it can be observed that even though a 400 m vessel could theoretically be worked on with more than 12 cranes simultaneously (Martin et al. 2015), most ports do not deploy more than six (The loadstar 2015) to eight (Martin et al. 2015) cranes on one ULCV.

Given these conditions, the performance requirements set by shipping companies are rather challenging. As an example, the carrier ‘Maersk’ has stated a target of up to 5000–6000 moves per day which corresponds to 208–250 moves per hour for ULCV calls (WorldCargo News 2011). Despite the advancements in equipment technology, ports still struggle to meet targets. A report from JOC Group shows that in 2013, the berth productivity range of the ten best performing terminals worldwide ranged from 131 to 179 moves per hour for vessel sizes larger than 8000 TEU. Clear differences can be observed with respect to the different regions worldwide. European and American terminals significantly lag behind those from Asia in this context (JOC Group 2014).

From the terminals’ perspective, an often-reported obstacle is increasing ULCV delays that prevent terminals from making optimal planning decisions (Sys et al. 2008). In addition, terminal operators report poorly stowed vessels that necessitate unproductive shuffle moves and thus lead crane optimization efforts to fail (Haralambides 2019). Further, the largest container vessels are no longer increasing in length but in beam and height, which does not allow for higher crane intensity (Martin et al. 2015). Longer port stays and intensified nautical constraints are also observed to lead to ‘knock-on effects’ (Lane and Moret 2014) that ultimately result in further off-schedule ULCV calls. Due to the high capacity and operational requirements (e.g. berthing space and crane capacity), it is very difficult for terminals to ensure flexibility or even to make up for delays. Better coordination between shipping companies and terminals is therefore vital to improve this situation (Lane and Moret 2014).

3.4 Coping with Peaks Induced by ULCVs

Large call sizes in combination with increased berth productivity ultimately lead to an intensified workload that is spread over a short period of time (Martin et al. 2015; Lane and Moret 2014), furthermore referred to as ‘peaks’. As we have outlined in the previous section, quayside operations directly link to other terminal subsystems, such as the yard storage area and the landside interface (Čerin and Beškovnik 2020).

Since containers to be loaded have to be provided in due time at berth and unloaded ones to be transported to the terminal yard, storage operations need to be efficient and scaled accordingly in order not to constrain quayside operations (Lane and Moret 2014). It can be observed that ULCV induced peaks correlate with higher storage utilization in terminal yards (Merk et al. 2015). As storage capacity cannot be extended endlessly, terminal operators try to make better use of available storage areas by reducing container dwell time through economic incentives for port users e.g., by increasing storage costs or reducing free storage time (Čerin and Beškovnik 2020).

Peaks also affect the landside interfaces of terminals, as incoming and outgoing containers need to be delivered and picked up in temporal relation to the port call. In fact, observations indicate that there exists a relationship between call sizes and increased hinterland traffic volume, especially on the road (Merk et al. 2015). Depending on the individual circumstances, an extension of port-related hinterland infrastructure may be necessary, as traffic volumes can exceed existing capacities (Russell et al. 2020; Mongelluzzo 2020). Especially ports with a high modal share of road transportation show increased gate congestion in relation to arrivals of larger vessels (Ozbas et al. 2014). Some terminals try to alleviate this issue through optimized gate processes such as the introduction of truck appointment systems that are meant to ease traffic volumes and make use of off-peak times (Merk et al. 2015).

The uneven distribution of workloads within the different subsystems of the terminal makes it difficult to provide the right amount of capacity while obtaining own economic objectives. This not only applies for superstructure and other equipment, but also to the available workforce. In this way, ULCV induced peaks reverse the trend of regularized and plannable personnel deployment, which has once been achieved through the standardized processes of modern terminals (Merk et al. 2015). Furthermore, peak effects do not just touch the physical flow of cargo but also impact administrative processes, data flows or custom procedures which need to be dimensioned properly as well (Merk et al. 2015). It can be expected that terminals with a high degree of automation have a better position to flexibly cope with ULCV induced peak workloads (Rijsenbrij and Wieschemann 2020).

3.5 Remodelling Seaport Network Structures

In their quest to optimize operations for ULCVs, shipping companies will take decisions that ultimately have great influence on port network structures (Sys et al. 2008). Thanks to increased bargaining power due to the consolidation within the shipping market, carriers persistently pursue to push berth productivity improvements in order to minimize non-productive port stay time. However, terminal operators have a hard time meeting these demands. An additional challenge is maritime access, which is either not given at all or only under certain constraints that are likely to limit flexibility and increase costs (see 3.2).

In addition to the economic constraints associated with the realization of economies of scale, the aforementioned aspects lead to the fact that shipping companies are reducing the number of port calls on ULCV services to fewer hubs, which leads to the emergence of hub-and-spoke networks (Haralambides 2019). Within these networks, port choice for ULCVs will especially be based on maritime accessibility, operational performance (Musso and Sciomachen 2020), connectivity but also on strategical considerations (Ducruet and Notteboom 2012. ULCV-ready ports within important trade areas that serve almost identical hinterlands find themselves in strong competition to stay one of the network hubs (Sys et al. 2008). Within these network configurations, carriers will constantly need to trade off higher slot utilization of their ultra large vessels against additional handling costs that occur due to necessary transhipment. Hence, it can be suggested that ‘hub ports’ with strong local hinterlands that can maintain a high share of import/export cargo will have the best conditions to maintain a sustainably important role within liner service networks (Ducruet and Notteboom 2012).

Experts suggest that maritime accessibility is likely to become an even more important factor of port choice for ULCVs. As a consequence, non-urban ports could take on an increasingly important role compared to ports in urban areas that do not provide enough room for adaptations (Merk 2018). An example provides the currently ongoing debate on Hapag-Lloyd’s recent announcement to reallocate ULCV services from the urban port of Hamburg to the greenfield terminal in Wilhelmshaven (WorldCargo News 2021a). Calls for stronger environmental restrictions as well as the risk of casualties in vulnerable urban areas add to these discussions.

4 Environmental Considerations of ULCVs

4.1 Ecologies of Scale

The impacts that the global shipping industry has on the environment are manifold. To encounter negative consequences, international regulations have been set in place that are often amended by national policies. In the following, an overview of the major possible impacts, shipping has on the environment, will be given with the affiliated regulations that are already in place.

Various studies have shown that certain components of anti-fouling paints are highly toxic to the marine environment. As the hull of a ship is almost permanently exposed to seawater, particles of the paint can enter the environment by abrasion or by disintegration. Scientific investigations have proved that these particles would poison marine life forms and enter the entire food chain. Therefore, certain components were banned from the use in anti-fouling paints since 2008 (MEPC 1990; IMO 2001).

At the end of a ship’s lifetime, which means it is either damaged or further operation does not pay off any longer for economic, ecologic or regulatory reasons, it gets wrecked and any valuable parts are recycled. Over the ship’s lifecycle, many potentially hazardous materials accumulate in a ship. These are, for example, residues of fuel oils, lube oils, cargo, paints. MEPC released different resolutions as guidelines to reduce environmental impacts of ship recycling (MEPC 2011a, 2012a, b, d, e, 2015).

The disposal of garbage at sea is another issue that endangers marine life and the marine environment and is regulated by MARPOL Annex V (MEPC 1973), which is updated at regular intervals. Ships above a certain size have to carry a garbage management plan and have to comply with the standards for shipboard incinerators (MEPC 2012c, 2014a, 2017).

Ships are also emitters of a considerable degree of noise. While there is regulation in place to protect the crew and the passengers from shipboard noise, there currently exists no regulation to protect the marine environment from ship noises (ILO 2006; MSC 2012a, b). The issue of ship noise impacts on marine mammals was discussed already in 2007, but currently only non-mandatory guidelines are in place (MEPC 2007, 2014b).

Another environmental issue are the exhaust emissions of ULCVs that are the direct result of the fuel used in a ship’s internal combustion engine. Exhaust emissions include greenhouse gases (GHG) and other components. Most notably of these other components are nitrous oxides (NOx), sulphur oxides (SOx) and particulate matter (PM) (Faber et al. 2020). The amount and the composition of the exhaust emissions depend on the specific machinery and the fuel in use. On modern day container vessels, different types of machinery are operated on different fuels. Therefore, the operation of vessels leads to a wide range of different emissions that are subject to various regulations that will be discussed detailed in Sect. 4.2.

None of these environmental impacts is unique to ULCVs and happens on any vessel. However, as has been discussed in Sect. 2.1, ULCVs have been developed in recent years with an increased nominal capacity while still maintaining the same dimensions. That means, the environmental impacts, that have been been discussed above are staying roughly the same for each vessel, while they can be attributed to an increasing amount of containers. As a result the environmental impact per TEU is decreasing. This effect could best be described as ‘ecologies of scale’ (Schlich and Fleissner 2005).Footnote 4

4.2 Regulating Emissions and Improving Energy Efficiency

These ‘ecologies of scale’ become especially apparent if the exhaust emissions of ULCVs are compared. Besides carbon dioxide (CO2) a vessel’s combustion engines also emit other GHGs that are measured in carbon dioxide equivalents (CO2e). In 2018 the combined CO2e-emissions of shipping, which includes international and domestic shipping as well as fishing, contributed to only 2.89% of the yearly global anthropogenic emissions. The shipping sector is dedicated to reduce its total CO2-emissions by 50% until 2050 in relation to 2008 levels (Faber et al. 2020; MEPC 2018). Because of a growing global trade volume and consequently a growing number of ships with a growing amount of cargo being underway, this requires a reduction of CO2e-emissions by 85% per individual ship (IMO n.d.). To tackle this issue, the Marine Environment Protection Committee (MEPC) of the IMO proposed various measures.Footnote 5 One is the Energy Efficiency Design Index (EEDI), which evaluates the energy efficiency of a vessel by defining a minimum energy efficiency baseline that new built ships need to achieve and that is increased every 5 years (MEPC 2011b, 2020), to ensure constant improvements of new built vessels. While the EEDI only aims at improving the efficiency of new built ships, MEPC adopted a similar index for the existing fleet, the Energy Efficiency Existing Ship Index (EEXI) in 2021 to be applied after 2022 (IMO 2021). Both indices, however, have been criticized to only make small contributions towards IMO’s decarbonization goals (Trivyza et al. 2020; Rutherford et al. 2020; Psaraftis and Kontovas 2021). EEDI and EEXI are accompanied by a so-called Ship Energy Efficiency Management Plan (SEEMP) and the Carbon Intensity Indicator (CII). The SEEMP is an operational mechanism to push ship owners to optimize the operational efficiency of a ship (MEPC 2011b), while the CII is an annual rating of the CO2-emissions of any singular vessel, which can be tied to incentives for a shipping company to invest in cleaner technologies (IMO 2020a, c, 2021).

The emission of NOx, SOx and PM is regulated by MARPOL since 1973. While these emissions do not have a global warming potential such as GHG, they come with negative local effects on populated areas such as cities in proximity to ports or navigation routes. Since the first of January 2020 (MEPC 2016) fuels have a maximum permissible amount of SOx and PM of 0.5% (MEPC 2019). Especially in ecologically sensitive regions, the so-called Emission Controlled Areas (ECA), ships need to comply with even stricter requirements regarding machinery and fuel. Vessels built after the first of January 2016 that are sailing in an ECA need to be equipped with a Tier-III-engine (MEPC 2018, 1973) and the maximum permissible amount of SOx and PM in the fuel is limited to 0.1% (MEPC 1973).

Due to these regulations, ULCV designs are constantly being improved with respect to their fuel efficiency. While the regulations are relevant for any ship, they also find application on ULCVs. However due to the ‘ecologies of scale’ ULCVs provide ecological benefits over smaller vessels and are constantly improving. In this section, an analysis of the energy efficiency changes of ULCVs over time is conducted, to estimate the improvements that have been made. For every year the fuel consumption of the largest ship by nominal capacity that has been delivered in that respective year has been estimated according to the formulas of the IMO (Faber et al. 2020). To calculate the fuel consumption, it was assumed that the vessels are operated at a uniform speed to compare them from a current point of view. Only the fuel consumption of the main engine is part of the estimation. The calculation does not account for any consumption from auxiliary engines or boilers, the amount of reefers on board or the bow thruster. The estimated fuel efficiency has then been divided by the amount of containers on board to create an indicator for the energy efficiency of the vessel. For the calculation a uniform slot utilization of 85% is assumed. The calculated energy efficiency is determined by a mass of fuel in kg that is required to transport 1 TEU by a distance of 1 nm. This indicator is denominated as kg/TEUmile.

The result of this estimation is depicted in Fig. 5. The diagram shows that clear improvements with regard to energy efficiency of ULCVs were made over time. In Sect. 2.2 it was mentioned that with the commissioning of the Maersk E-class in 2006 a new chapter in ship size growth was opened. At the time of its commissioning, the energy efficiency of the E-class was significantly improved compared to the largest vessel that was commissioned 10 years earlier. Because the estimation does not include other factors such as the operation of auxiliary engines, boilers or the amount of reefer containers, the energy efficiency only depends on the main engine and the operating speed as well as the slot utilization and reflects the energy efficiency of the ship at sea. Because a uniform slot utilization has been assumed, an increase or reduction would lead to a more or less uniform increase or reduction of the energy efficiency among the vessels.

Development of Energy Efficiency of ULCVs. Own diagram based on CRSL (2021a)

Figure 6 shows the improvements of energy efficiency in retrospective. To even out fluctuations, the energy efficiency of the analysis has been grouped into tranches of 5 years and their average energy efficiency was determined. Then the fuel consumption of the latest tranche, which contains the ULCV from 2015 to 2019, was compared to earlier tranches of ships. The figure shows that a ULCV from the latest tranche uses about 45% less fuel per TEUmile than a vessel from the first tranche, in which the Maersk C-class, which is not considered as a ULCV, was commissioned. Compared to the third tranche, which includes the Maersk E-class that coined the term ‘ULCV’, the last tranche still utilizes about 27% less fuel per amount of transport work.

Energy efficiency of a modern day ULCV compared to older vessels. Energy efficiency of different tranches is shown. Own diagram based on CRSL (2021a)

Generally, there have been improvements to the energy efficiency of ULCVs that can be verified by an estimation of the energy efficiency. However, Fig. 5 also shows that improvements of the energy efficiency in the recent years have been achieved in rather small steps. Part of the reason is that the main engines are already highly optimized and achieve very low specific fuel oil consumptions, which is the mass of fuel that is required to produce a specific amount of energy. Due to this already high optimization of marine engines, the room for further improvements is small and operational measures such as weather routing or slow steaming become more relevant, because they still provide a leverage to the fuel consumption of a vessel (Faber et al. 2020). To further improve the fuel efficiency, operational measures or technical solutions such as air lubrication or wind assistance could be utilized. In the most recent ULCVs from 2020 and 2021 ship owners often implement dual fuel engines, that do not only use oils as a fuel but also Liquefied Natural Gas (LNG). While the operation of vessels with LNG results in lower CO2-emissions, which gives the vessel a good EEDI rating, LNG is mostly composed of methane, a strong GHG, which can result in a harsh increase of CO2e-emissions if leaked into the environment. The amount of this so-called methane slip that is the result of an incomplete combustion heavily depends on the engine that is installed. In the worst case, the use of LNG in dual fuel engines does result in significantly lower CO2-emissions but in an increase of CO2e-emissions. If the methane slip over the life cycle of LNG can be reduced or prevented, this fuel could provide a new leverage to further improve the efficiency of ULCVs (Pavlenko et al. 2020). While some shipping companies build their ships with LNG dual fuel engines (CMA CGM n.d.), others are using methanol (A.P. Moller - Maersk 2021) or even consider ammonia as potential future fuels (Lloyd’s Register 2019), that could even be produced from renewable resources. In a recent study, the DNV GL considers several future fuels. Among LNG, methanol and ammonia from renewable sources, hydrogen, that is used in fuel cells, is part of the maritime future energy mix in some of the considered scenarios (DNV GL 2020).

4.3 Dredging for the Future

Dredging in ports is primarily done to accommodate large vessels and to allow large vessels to pass each other with a safe distance. ULCVs are one of the main reasons for dredging that is performed in ports all around the world. The environmental impacts that dredging has on the marine environment cannot be attributed solely to ULCVs but rather to the cascading effects with larger vessels replacing smaller units, as has been demonstrated in Sect. 2.2 (European Dredging Association n.d.).

In the context of ULCVs mostly two of these types of dredging are important. As has been discussed in Sect. 2.1, ships have always been getting bigger with ULCVs always being the peak of this evolution. While ports have often developed historically according to the needs of the time which maybe the near future in hindsight, in many cases they are not prepared for vessels the size of a modern day ULCV. To accommodate these large vessels the infra- and superstructure of the ports need to be modified as already discussed in Sect. 3.1. Modifications to the infrastructure, such as the enlargement or deepening of channels, berths or basins require dredging with the aim of creating or modifying infrastructure. This is called ‘capital dredging’. Due to different reasons, such as waves and tides, sediments are transported with the water and accumulate in channels, berths or basins of a port, where they can reduce the depth of a channel. To ensure that the port and the adjoining waters remain navigable, the so-called maintenance dredging is carried out at intervals, and the accumulated sediments are dredged (Ports Australia 2016; European Dredging Association n.d.).

Dredging is often considered as an interference into existing ecosystems. While it is obvious that dredging can be an issue to these ecosystems, the extent of the impact of a dredging measure is difficult to evaluate and the public discussion about it can lead to serious delays, especially when it evolves around capital dredging. A prime example for such a delay is the lengthy discussion about the dredging of the river Elbe in Hamburg (Germany), which started in 2002 and was ended by the approval of the works in 2020 (Grabbe 2017; Groll 2020; Merk et al. 2015). The effects of dredging on the marine environment are investigated intensively by many researchers. Generally speaking, the environment is affected in many different ways by dredging. During the dredging work itself, noise levels increase significantly above normal levels, which could be harmful especially to marine mammals (Todd et al. 2015). The process of dredging causes the so-called turbidity plumes, an increased amount of sediments in the water that have short-term effect on the quality of water (Ports Australia 2016). The turbidity plumes can negatively impact the light penetration of the water, which has the potential to degrade ecologically important habitats close to the dredging operation that are sensitive to any change of their environment. The extent of the effect on flora and fauna depends on the specific sensitivity of the specie, with some being able to adapt to changes and others not (Erftemeijer et al. 2012; Ports Australia 2016; Erftemeijer and Lewis 2006). Sediments can accumulate different toxins and pollutants over time. Dredging operations disturb these sediments and can release these toxins and pollutants into the water and surrounding habitats (Johnston 1981; Todd et al. 2015). Another impact is the change of the sediment structure due to dredging, which could become unsuitable as a habitat for some species. Again, the extent of the effect is varying on the predominant species of flora and fauna as well as the composition of the sediment before the dredging. Dredging can also have a positive short-term effect. Whirling up sediments can release nutrients into the water and increase the supply of food available for different species in an area, leading to a temporary rise of species abundance in the dredging area (Todd et al. 2015).

To ensure that the interference of marine dredging works on the environment is kept at a minimum, an environmental risk assessment is a crucial part of the planning stage. It shall be ensured that any unnecessary environmental impact is avoided and that any remaining impacts are mitigated and offset. Any impact that dredging has on water and sediment quality has to be evaluated. Additional aspects such as impacts or potential losses of marine flora and fauna, cultural heritage, fishing and shipping activities and any changes to current and water flows are to be considered (Ports Australia 2016). Concluding, studies do show that dredging negatively impacts marine life and the environment. It is indicated that the extent of these effects depends on the specific species, with some being more sensitive to disturbances than others (Erftemeijer and Lewis 2006; Erftemeijer et al. 2012; Todd et al. 2015; Johnston 1981). It is hinted that dredging can even have short-term positive impacts (Todd et al. 2015). In any case, negative effects outweigh the positive effects and it can take up to 10 years after the dredging operation until the area has fully recovered from the interference (Newell et al. 1998; Todd et al. 2015).

5 Conclusion

5.1 Various Effects of Ever Larger Ships

The discussion on seaport systems as well as on environmental considerations has shown that cost benefits realized at sea may come with negative effects in other external systems. Potential negative impacts on aquatic ecosystems and increasing logistical, infrastructural and superstructural challenges in the entire transport chain become more and more complex and extreme as the size and capacity of ULCVs further increase. Economic advantages for liner shipping companies through economies of scale therefore come at the expense of diseconomies of scale, which must be shouldered, to a large extent, by the general public.

ULCVs, meaning container ships that can no longer pass through the new locks of the Panama Canal due to their dimensions, have assumed a dominant role within the global container ship fleet since their introduction in 2006. While these vessels initially possessed nominal capacities in the range of 15,000 to 16,000 TEU, no ULCV with less than 19,000 TEU has been put into service since 2019. The current order book for new containerships indicates that only ULCVs with more than 23,000 TEU will become operational in the coming years and that a large part of the future growth in the total capacity of the global containership fleet will fall into this segment.

With regard to seaport systems, it becomes obvious that the rise of ULCVs has created a very demanding environment for port and terminal operators. While those vessels are often mentioned in connection with significant cost advantages achieved through ‘economies of scale’, it is argued that ports and terminals have rather become ‘sweating ports’ that suffer from ‘diseconomies of scale’ under the influence of large vessels (Haralambides 2019; Malchow 2017). On the one hand, this refers to necessary infra- and superstructure adaptions that are connected with huge investments, often subsidized by taxpayers’ money. On the other hand, shipping companies as the terminals’ main customers set increased operational performance requirements that can hardly be fulfilled at the moment and call for more and faster equipment as well as more flexibility. In connection with lower call frequencies and workload peaks as a result of increased call sizes, this environment is likely to lower the profitability of terminal operations. However, it is not guaranteed that the efforts to meet ULCV requirements will ultimately pay off by means of increased throughput, as shipping companies are in the process of reshaping their service structures that involve fewer ports of call within hub-and-spoke-networks.

It has become apparent that container ships come with various impacts on the environment. While these impacts are not unique to ULCV, it was demonstrated that these vessels provide an ecologic leverage over smaller units since they enable an increasing nominal capacity, while maintaining comparable outer dimensions. The ecological impact that a ULCV has can therefore be distributed among a higher number of containers. On a per-box-base the ecological impact is decreasing with the deployment of ULCV. This effect can best be described as ‘ecologies of scale’. Hence, it could be demonstrated that the energy efficiency of ULCV has improved drastically over the last decades: due to improved engine efficiency and improved operational measures, a modern day ULCV is about 40% more energy efficient. Since engines have been highly optimized, further potential for energy efficiency gains from engine optimization is limited. Additional emission savings could be contributed from operational measures and additional technical solutions such as wind assistance or from future fuels. Even though it was shown that ULCVs do offer ecologic benefits mainly from improved machinery and ‘ecologies of scale’, dredging in port areas is mainly done to keep ports up with the increasing ship sizes. While it is hinted that capital dredging indeed can have short-term benefits on the marine environment, they are far outweighed by negative effects that often do have a long-term effect.

5.2 Economies and Diseconomies of Scale: The Discussion Goes into the Next Round

Due to the strong increase in orders, especially for ULCV new buildings since the fourth quarter of 2020, the future capacity growth of the world container fleet will be mainly driven by this largest ship segment in the coming years. It has been shown that the growth in size can in principle be continued and that the ULCV-class of MGX-24 ships could be surpassed by ships with up to 30,000 TEU, which could be significantly longer and wider than the largest ships in service today.

While consulting firms and economists have been grappling for some time with the question of how much and under what conditions further growth in the size of container ships can still lead to measurable economies of scale for liner shipping companies, diseconomies of scale of ULCVs have so far been described mainly in qualitative terms. Whereas negative ecological impacts, e.g. due to dredging, are difficult to quantify monetarily due to their long-term nature, this does not apply to ULCV-related modernization and maintenance costs of seaport network structures. Especially in this area, further research is needed to better estimate monetary consequences of ULCVs and possibly even larger units in the future. If, when and to which magnitude gigantism in container shipping will be carried on depends largely on whether the liner shipping companies will still be able to profit from economies of scale with ever larger ships and to what extent external diseconomies of scale are tolerated by the respective actors, such as the general public. Today, some voices even call for a limitation of vessel sizes in order to prevent ports from becoming unprofitable and public bodies from excessive spending in infrastructure that comes without significant compensation by vessel operators (WorldCargo News 2021b; Malchow 2017).

Notes

- 1.

‘Length over all’, which describes the maximum length of a vessel’s hull.

- 2.

Air draught needs to be taken into account with respect to crossing bridges. Prominent examples are the Koehlbrand Bridge in Hamburg or the Tsing Ma Bridge in Hong Kong, which do not allow for enough air draught for ULCV even at favourable tidal conditions.

- 3.

The outreach needs to account for the beam of the vessel as well as the distance from the vessels hull to the centre of the cranes’ rail system at berth. As a ‘rule of thumb’, the necessary outreach in meter can be estimated by multiplying the number of rows by 2.5 m and adding 5 m for the distance between the crane and the vessel (PEMA (2018)). Hence, a vessel with 24 rows would require an outreach of more than 65.0 m.

- 4.

The term ‘ecologies of scale’ according to the author describes the effect that the ecological impact of a production line decreases as the amount of produced items is increased, similar to the term ‘economy of scale”. In the context of this article, the amount of items translates to a service provided, i.e. the amount of containers transported.

- 5.

Also, the European Union is pushing the maritime sector to reduce the fuel consumption its CO2-emissions. In 2015 the EU adopted legislation to a program to monitor, report and verify CO2-emissions from the shipping sector that has been proposed in 2013. The aim of the EU is to take regulations to a practical level and use the findings in the discussions with the IMO (European Commission (2013, 2020)).

References

A.P. Moller - Maersk.: A.P. Moller - Maersk joins Methanol Institute. https://www.maersk.com/news/articles/2021/03/24/ap-moller-maersk-joins-methanol-institute (2021). Accessed 21 June 2021

Alphaliner: The next step for jumbo boxships: the ‘Megamax-24’. Alphaliner Weekly Newsletter. 2017(45), 19–22 (2017)

Alphaliner: The ‘gigamax’: would a ‘post-megamax’ ship make any sense? Alphaliner Weekly Newsletter. 2021(22), 1–5 (2021)

American Bureau of Shipping.: ABS Record Eugen Maersk. https://www.eagle.org/portal/#/absrecord/details. (2021). Accessed 23 April 2021

Andrés, S., Piniella, F.: Aids to navigation systems on inland waterways as an element of competitiveness in ULCV traffic. J. Traffic. Transp. Eng. 7, 1–18 (2017). https://doi.org/10.7708/ijtte.2017.7(1).01

Böse, J.W.: General considerations on terminal planning, innovations and challenges. In: Böse, J.W. (ed.) Handbook of Terminal Planning, pp. 3–27. Springer International Publishing, Cham (2020)

Carbone, V., Martino, M.D.: The changing role of ports in supply-chain management: an empirical analysis. Marit. Policy Manag. 30, 305–320 (2003). https://doi.org/10.1080/0308883032000145618

Cariou, P., Cheaitou, A.: Cascading effects, network configurations and optimal transshipment volumes in liner shipping. Marit. Econ. Logist. 16, 321–342 (2014). https://doi.org/10.1057/mel.2014.4

Čerin, P., Beškovnik, B. Impact of container vessels capacity 15.000 TEU and more on existing container terminals. J. Mar. Transp. Sci. 3, 49–61 (2020). https://doi.org/18048/2020.00.03

CMA CGM.: The CMA CGM JACQUES SAADE, the world’s first 23,000 TEU powered by LNG. https://cmacgm-group.com/en/launching-cmacgm-jacques-saade-world%27s-first-ultra-large-vessel-powered-by-lng (n.d.). Accessed 21 June 2021

CRSL.: Shipping Intelligence Network (SIN). Clarksons Research Services Limited. https://sin.clarksons.net/ (2021a). Accessed 24 June 2021

CRSL.: World Fleet Register (WFR). Clarksons Research Services Limited. https://www.clarksons.net/wfr/ (2021b). Accessed 24 June 2021

de Haas, J.: Gard Guidance on Freight Containers. Gard, Arendal (2016)

Det Norske Veritas AS: Container Ship Update. Det Norske Veritas AS, Høvik, Norway (2013)

DNV GL. Maritime Forecast to 2050 (2020)

Ducruet, C., Notteboom, T.: Developing liner service networks in container shipping. In: Song, D.-W., Panayides, P.M. (eds.) Maritime Logistics: A Complete Guide to Effective Shipping and Port Management, pp. 77–100. Kogan Page, London (2012)

Erftemeijer, P.L., Lewis, R.R.R.: Environmental impacts of dredging on seagrasses: a review. Mar. Pollut. Bull. 52, 1553–1572 (2006). https://doi.org/10.1016/j.marpolbul.2006.09.006

Erftemeijer, P.L., Riegl, B., Hoeksema, B.W., Todd, P.A.: Environmental impacts of dredging and other sediment disturbances on corals: a review. Mar. Pollut. Bull. 64, 1737–1765 (2012). https://doi.org/10.1016/j.marpolbul.2012.05.008

European Commission: Integrating Maritime Transport Emissions in the EU’s Greenhouse Gas Reduction Policies: COM(2013) 479 Final. European Commission, Brussels, Belgium (2013)

European Commission: 2019 Annual Report on CO2 Emissions from Maritime Transport: SWD(2020) 82 Final. European Commission, Brussels, Belgium (2020)

European Dredging Association.: EuDA - About dredging - Definitions. https://european-dredging.eu/Definitions (n.d.). Accessed 8 June 2021

Faber, J., Hanayama, S., Zhang, S., Pereda, P., Comer, B., Hauerhof, E., et al.: Fourth IMO GHG Study 2020: Reduction of GHG Emissions from Ships, Delft (2020)

Ge, J., Zhu, M., Sha, M., Notteboom, T., Shi, W., Wang, X.: Towards 25,000 TEU vessels? A comparative economic analysis of ultra-large containership sizes under different market and operational conditions. Marit. Econ. Logist. (2019). https://doi.org/10.1057/s41278-019-00136-4

Grabbe, H.: Elbvertiefung: Alles im Fluss. https://www.zeit.de/2017/07/elbvertiefung-hamburg-hafen-pro-contra (2017). Accessed 14 June 2021

Groll, T.: Elbvertiefung: Bundesgericht genehmigt Ausbau der Elbe endgültig. https://www.zeit.de/politik/deutschland/2020-06/elbvertiefung-hamburg-bundesverwaltungsgericht-leipzig-umweltschutz-klage (2020). Accessed 14 June 2021

Hamburg Port Authority: Port Information Guide – Port of Hamburg. Hamburg Port Authority, Hamburg (2018)

Hansestadt Bremisches Hafenamt: Port Information Guide – Port of Bremerhaven. Hansestadt Bremisches Hafenamt, Bremerhaven (2021)

Haralambides, H.: Gigantism in container shipping, ports and global logistics: a time-lapse into the future. Marit. Econ. Logist. 21, 1–60 (2019). https://doi.org/10.1057/s41278-018-00116-0

Heaney, S., Poore, D., Behera, S., Dixon, M., Kumar, A., Tomar, R., et al.: Container: Forecaster & Annual Review 2020/21. Quarter 3 September 2020, London (2020)

Hill, D.: ZPMC Delivers 2 STS Cranes to RWG in Rotterdam. Heavy Lift News. https://www.heavyliftnews.com/zpmc-delivers-2-sts-cranes-to-rwg-in-rotterdam/ (2020a, April 23). Accessed 12 June 2021

Hill, D.: Zhen Hua 26 unloads 2 ZPMC STS Cranes in Hamburg. Heavy Lift News. https://www.heavyliftnews.com/zhen-hua-26-unloads-2-zpmc-sts-cranes-in-hamburg/ (2020b, May 11). Accessed 12 June 2021

ILO (International Labour Organization): Maritime Labour Convention. ILO, Geneva (2006)

IMO.: IMO Action to Reduce GHG Emissions from International Shipping: Implementing the Initial IMO Strategy on Reduction of GHG Emissions from Ships (n.d.)

IMO (International Maritime Organization): International Convention on the Control of Harmful Anti-Fouling Systems on Ships, 2001. IMO, London (2001)

IMO (International Maritime Organization).: IMO Environment Committee approves amendments to cut ship emissions. https://www.imo.org/en/MediaCentre/PressBriefings/pages/42-MEPC-short-term-measure.aspx (2020a). Accessed 11 June 2021

IMO (International Maritime Organization): International Convention for the Safety of Life at Sea, 1974: SOLAS 1974 (2020th ed., IMO Publication). International Maritime Organization, London (2020b)

IMO (International Maritime Organization).: IMO working group agrees further measures to cut ship emissions. https://www.imo.org/en/MediaCentre/PressBriefings/pages/36-ISWG-GHG-7.aspx (2020c). Accessed 21 May 2021

IMO (International Maritime Organization).: Further shipping GHG emission reduction measures adopted. https://www.imo.org/en/MediaCentre/PressBriefings/pages/MEPC76.aspx (2021). Accessed 24 June 2021

JOC Group: Berth Productivity: The Trends, Outlook and Market Forces Impacting Ship Turnaround Times. JOC Group (2014)

Johnston, S.A.: Estuarine dredge and fill activities: a review of impacts. Environ. Manag. 5, 427–440 (1981). https://doi.org/10.1007/BF01866820

Koutroukis, G., Papanikolaou, A., Nikolopoulos, L., Sames, P., Köpke, M.: Multi-objective optimization of container ship design. In: Soares, C., Peña, F. (eds.) Developments in Maritime Transportation and Exploitation of Sea Resources, pp. 477–489. CRC Press, Boca Raton (2013)

Lane, A., Moret, C.: The Impact of Ever Larger Vessels on Terminals. CTI Consultancy, Singapore (2014)

Lian, F., Jin, J., Yang, Z.: Optimal container ship size: a global cost minimization approach. Marit. Policy Manag. 46, 802–817 (2019). https://doi.org/10.1080/03088839.2019.1630760

Liebherr Group.: Crane Sizes and Technical Specifications. https://www.liebherr.com/en/deu/products/maritime-cranes/port-equipment/container-bridges/ship-to-shore-container-cranes.html#!/mcm-sts-accordian-start=mcm-sts-accordion-crane-sizes-start (2021). Accessed 11 June 2021

Lloyd’s Register.: Industry project to design ammonia-fuelled 23k ULCS concept. https://www.lr.org/en/latest-news/aip-ammonia-fuelled-ulcs/ (2019). Accessed 21 June 2021

Malchow, U.: Growth in containership sizes to be stopped? Marit. Bus. Rev. 2, 199–210 (2017). https://doi.org/10.1108/MABR-01-2017-0001

Mallin, P., To, A.: Ports Must Adapt to Mega-Ships to Remain Competitive. Maritime Information Services, London (2016)

Martin, J., Martin, S., Pettit, S.: Container ship size and the implications on port call workload. Int. J. Shipp. Transp. Logist. 7, 553 (2015). https://doi.org/10.1504/IJSTL.2015.072016

MEPC (Marine Environment Protection Committee).: International Convention for the Prevention of Pollution from Ships, MARPOL 73/78 (1973)

MEPC (Marine Environment Protection Committee). Measures to Control Potential Adverse Impacts Associated With use of Tributyl Tin Compounds in Anti-Fouling Paints: MEPC.46(30) (1990)

MEPC (Marine Environment Protection Committee).: Shipping noise and marine mammals: MEPC 57/INF.4 (2007)

MEPC (Marine Environment Protection Committee).: Guidelines for the Development of the Inventory of Hazardous Materials: MEPC.197(62) (2011a)

MEPC (Marine Environment Protection Committee).: Inclusion of regulations on energy efficiency for ships in MARPOL Annex VI: MEPC.203(62) (2011b)

MEPC (Marine Environment Protection Committee).: Guidelines for Safe and Environmentally Sound Ship Recycling: MEPC.210(63) (2012a)

MEPC (Marine Environment Protection Committee).: Guidelines for the Authorization of Ship Recycling Facilities: MEPC.211(63) (2012b)

MEPC (Marine Environment Protection Committee).: Guidelines for the Development of Garbage Management Plans: MEPC.220(63) (2012c)

MEPC (Marine Environment Protection Committee).: Guidelines for the Inspection of Ships Under the Hong Kong Convention: MEPC.223(64) (2012d)

MEPC (Marine Environment Protection Committee).: Guidelines for the Survey and Certification of Ships Under the Hong Kong Convention: MEPC.222(64) (2012e)

MEPC (Marine Environment Protection Committee).: Standard Specification for Shipboard Incinerators: MEPC.244(66) (2014a)

MEPC (Marine Environment Protection Committee).: Guidelines for the Reduction of Underwater Noise from Commercial Shipping to address adverse Impacts on Marine Life: MEPC.1/Circ.833 (2014b)

MEPC (Marine Environment Protection Committee).: Guidelines for the Development of the Inventory of Hazardous Material: MEPC.269(68) (2015)

MEPC (Marine Environment Protection Committee).: Effective Date of Implementation of the Fuel Oil Standard in Regulation 14.1.3 of MARPOL Annex VI: MEPC.280(70) (2016)

MEPC (Marine Environment Protection Committee).: Guidelines for the Implementation of MARPOL Annex V: MEPC.295(71) (2017)

MEPC (Marine Environment Protection Committee).: Initial IMO Strategy on Reduction of GHG Emissions From Ships: MEPC.304(72) (2018)

MEPC (Marine Environment Protection Committee).: Guidelines for Consistent Implementation of the 0.50% Sulphur Limit under MARPOL Annex VI: MEPC.320(74) (2019)

MEPC (Marine Environment Protection Committee).: Procedures for sampling and verification of the sulphur content of fuel oil and the Energy Efficiency Design Index (EEDI): MEPC.324(75) (2020)

Merk, O.: Container Ship Size and Port Relocation: Discussion Paper, Paris (2018)

Merk, O., Busquet, B., Aronietis, R.: The Impact of Mega-Ships: Case-Specific Policy Analysis (2015)

Mongelluzzo, B. LA-LB proves ability to handle mega-ships, but landside pressures remain. https://www.joc.com/port-news/terminal-operators/la-lb-proves-ability-handle-mega-ships-landside-pressures-remain_20200623.html (2020). Accessed 21 June 2021

MSC (Maritime Safety Committee).: Adoption of Amendments to the International Convention for the Safety of Life at sea, 1974, as Amended: MSC.338(91) (2012a)

MSC (Maritime Safety Committee).: Adoption of the Code on Noise Levels on Board Ships: MSC.337(91) (2012b)

Musso, E., Sciomachen, A.: Impact of megaships on the performance of port container terminals. Marit. Econ. Logist. 22, 432–445 (2020). https://doi.org/10.1057/s41278-019-00120-y

Newell, R.C., Seiderer, L.J., Hitchcock, D.R.: The impact of dredging works in coastal waters: a review of the sensitivity to disturbance and subsequent recovery of biological resources on the sea bed. Oceanogr. Mar. Biol. Annu. Rev. 36, 127–178 (1998)

Notteboom, T.: The adaptive capacity of container ports in an era of mega vessels: the case of upstream seaports Antwerp and Hamburg. J. Transp. Geogr. 54, 295–309 (2016)

Ozbas, B., Spasociv, L., Campo, M., Besenski, D.: Analyses of interactions between the marine terminal and highway operations (2014)

Panama Canal Authority. OP notice to shipping no. N-1-2021: Vessel Requirements. Panama Canal Authority (2021)

Park, N.K., Suh, S.C.: Tendency toward mega containerships and the constraints of container terminals. J. Mar. Sci. Eng. 7, 131 (2019). https://doi.org/10.3390/jmse7050131

Pavlenko, N., Comer, B., Zhou, Y., Rutherford, D.: The climate implications of usinrijg LNG as a marine fuel (2020)

PEMA (Port Equipment Manufacturers Association).: 7th Annual Ship-to-Shore Crane Survey: Global Deliveries 2017 (2018)

PIANC.: Harbour approach channels design guidelines: report no 121–2014 (2014)

Ports Australia: Environmental Code of Practice for Dredging and Dredged Material Management. Ports Australia, Sydney (2016)

Psaraftis, H.N., Kontovas, C.A.: Decarbonization of Maritime transport: is there light at the end of the tunnel? Sustainability. 13, 237 (2021). https://doi.org/10.3390/su13010237

Rijsenbrij, J., Wieschemann, A.: A powerful union for sustainable container terminal design. In: Böse, J.W. (ed.) Handbook of Terminal Planning. Springer International Publishing, Cham (2020)

Rodrigue, J.-P. (2021). Channel Depth at Major North American Container Ports | The Geography of Transport Systems. https://transportgeography.org/contents/chapter6/port-terminals/channel-depth-ports-north-america/. Accessed 28 June 2021

Russell, D., Ruamsook, K., Roso, V.: Managing supply chain uncertainty by building flexibility in container port capacity: a logistics triad perspective and the COVID-19 case. Marit. Econ. Logist. (2020). https://doi.org/10.1057/s41278-020-00168-1

Rutherford, D., Mao, X., & Comer, B. (2020). Potential CO2 Reductions under the Energy Efficiency Existing Ship Index

Sahoo, P.K.: Principles of Marine Vessel Design: Concepts and Design Fundamentals of Sea Going Vessels. World Scientific Publishing Company, Singapore (2021)

Scheldecoördinatiecentrum Vlissingen.: VTS-Scheldt - Tijpoort in relatie tot het toelatingsbeleid. https://www.vts-scheldt.net/nautisch/tijpoorten (2021). Accessed 16 June 2021

Schlich, E., Fleissner, U.: The ecology of scale: assessment of regional energy turnover and comparison with global food (5 pp). Int. J. Life Cycle Assess. 10, 219–223 (2005). https://doi.org/10.1065/lca2004.09.180.9

Schönknecht, A.: Maritime Containerlogistik: Leistungsvergleich von Containerschiffen in intermodalen Transportketten. Springer, Berlin/Heidelberg (2009)

Soderberg, E.: The effect of ultra large container vessels on cranes and infrastructure (2017)

Specht, P., Kotzab, H., Arendt, F. Uncertainty affecting seaport-hinterland coordination: the case of information on cargo availability. In: 19th International Conference on Transport Science, Portoroz, Slovenia pp. 313–319 (2020)

Stopford, M.: Maritime economics. Routledge, London, New York (2009)

Stoschek, O., Leschka, S., Hein, C., Brüning, A.: Optimizing pier structures using dynamic mooring forces modelling. PIANC-World Congress Panama City, Panama (2018)

Sys, C., Blauwens, G., Omey, E., van de Voorde, E., Witlox, F.: In search of the link between ship size and operations. Transp. Plan. Technol. 31, 435–463 (2008). https://doi.org/10.1080/03081060802335109

THB.: TEU-Upgrade für „Emma Maersk“ und Co. https://www.thb.info/rubriken/detail/news/teu-upgrade-fuer-emma-maersk-und-co.html (2018). Accessed 23 April 2021

The Loadstar.: Measuring port performance (2015)

Todd, V.L.G., Todd, I.B., Gardiner, J.C., Morrin, E.C.N., MacPherson, N.A., DiMarzio, N.A., et al.: A review of impacts of marine dredging activities on marine mammals. ICES J. Mar. Sci. 72, 328–340 (2015). https://doi.org/10.1093/icesjms/fsu187

Trivyza, N.L., Rentizelas, A., Theotokatos, G.: A comparative analysis of EEDI versus lifetime CO2 emissions. J. Mar. Sci. Eng. 8, 61 (2020). https://doi.org/10.3390/jmse8010061

van Ham, J.C.: The feasibility of mega container vessels. European Transport\Trasporti Europei. 25(25–26), 89–98 (2005)

Vantorre, M., Candries, M., Verwilligen, J.: Optimisation of tidal windows for deep-drafted vessels by means of a probabalistic approach policy for access channels with depth limitations (2014)

Wijnolst, N., Scholtens, M., Waals, F.: Malacca-Max: the Ultimate Container Carrier Delft Marine Technology Series, vol. 14. Delft Univ. Press, Delft (1999)

WorldCargo News.: Triple E ships - 6000 moves in 24 hours. https://www.worldcargonews.com/news/news/triple-e-ships%2D%2D-6000-moves-in-24-hours-29178 (2011). Accessed 21 June 2021

WorldCargo News.: Hapag-Lloyd to start calling JWP Wilhelmshaven? https://www.worldcargonews.com/news/news/hapag-lloyd-to-start-calling-jwp-wilhelmshaven-66373 (2021a). Accessed 21 June 2021

WorldCargo News.: Staying in the game as ships grow. https://www.worldcargonews.com/in-depth/staying-in-the-game-as-ships-grow (2021b). Accessed 24 June 2021

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2021 The Author(s)

About this chapter

Cite this chapter

Jungen, H., Specht, P., Ovens, J., Lemper, B. (2021). The Rise of Ultra Large Container Vessels: Implications for Seaport Systems and Environmental Considerations. In: Freitag, M., Kotzab, H., Megow, N. (eds) Dynamics in Logistics. Springer, Cham. https://doi.org/10.1007/978-3-030-88662-2_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-88662-2_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-88661-5

Online ISBN: 978-3-030-88662-2

eBook Packages: Business and ManagementBusiness and Management (R0)