Abstract

This paper reports on an experimental study on user interface design in complex electronics manufacturing systems to measure the difference between ecological interface design (EID) and user-centered design (UCD). Based on cognitive psychology and human factors theory, we conducted a comparative research study. Prototypes of the interface were designed based on the EID and UCD which were undergoing NASA-TLX to evaluation the subjective workload of the users. The main findings of this study were as follows: (1) we found that the ecological interface design and user-centered design had significant differences in each levels; (2) the ecological interface design has a significant better effect on subjective workload compare to user-centered design in the complex electronics manufacturing systems (P < 0.05). The research results can help interface designers to deeply understand the difference between EID and UCD, which could guide the design of user interface in the complex industrial scenarios.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Ecological interface design

- User-centered design

- User interface

- Complex electronics manufacturing systems

1 Introduction

As we known, user-centered design (UCD) and ecological interface design (EID) are both of the two important design methods in the user interface design area. User-centered design is a research framework of design processes that the psychological limitations and physiological limitations of end users are given extensive attention at each stage of the interface design process [1]. Ecological interface design is an approach to user interface design that was introduced specifically for complex sociotechnical, real-time, and dynamic information systems. It has been applied in a variety of domains including process control such as nuclear power plants, aviation and complex electronics manufacturing systems, etc. [2].

Eason pointed out that sociotechnical system in manufacturing systems is an approach to complex organizational work design that researches the interaction between the user and user interface [3]. However, Vicente & Rasmussen described that complex manufacturing system designed based on traditional methods frequently loses the ability to support sudden failure in system design. System safety is often compromised by the operators’ inability to adapt to new and unfamiliar situations [4]. Vicente argued that ecological interface design attempts to provide the operators with the necessary tools and information to become active problem solvers as opposed to passive monitors, particularly during the development of unforeseen failure events [5]. Upton pointed out that manufacturing systems were complex sociotechnical systems, the user interface is also beginning to show information complexity, real-time and dynamic features [6]. Situational awareness (SA) is the field of study concerned with understanding of the environment critical to end users in complex and dynamic work conditions. Designing for situation awareness helps designers understand how user acquire and deal with visual information in user interface of complex electronics manufacturing environment [7].

Currently, user interface in complex electronics manufacturing systems is increasing in information complexity. To take advantage of huge amounts of information in the user interface, we need information displays that transform production data into meaningful information organization. This means developing user interface that clearly connect performance goals to technical processes and physical electronics manufacturing equipment. Behind every user interface in complex electronics manufacturing systems, there lays different degree of information complexity. The solution isn’t to reduce information, but to transform it into clear information architecture [8].

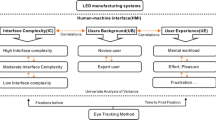

The user interface is the core to control of the electronics manufacturing equipment, user interface is the bridge of transmits the user command to the electronics manufacturing equipment. There were huge differences between the environments, design object, use pattern with the traditional consumer products (especially IT products). As a result, it is becoming more and more difficult for UI designers to anticipate events that occur within electronics manufacturing systems. However, little research has been focused on different subjective workload of the users between EID and UCD method with the user interface design in complex electronics manufacturing systems. Therefore, we started this design research. The theoretical framework of the study was shown in the Fig. 1.

2 Research Method

2.1 Interface Design Methodology: EID vs UCD

User-centered design used to identify user behavior and user’s mental model and incorporating them into the user interfaces [9]. The UCD method used to focuses on single user interactions between the user and the user interface [10]. EID contains the abstraction hierarchy (functional purpose; abstract function; generalized function; physical function; physical form) and skills, rules, knowledge (skill-based level; rule-based level; knowledge-based level) framework [11, 12], as shown in Fig. 2.

In summary, EID and UCD was two different interface design methodology. (1) EID focuses of the analysis on the work domain or environment, which differs from UCD focus on the end user or a specific task. (2) EID focus of the analysis on the complex systems, real-time and dynamic systems, in contrast, UCD focus on the simple system, everyday use and static systems. (3) EID theory based on the abstraction hierarchy (AH), The skills, rules, knowledge (SRK) method, in contrast, UCD theory based on the interviews, focus groups, usability test and questionnaire method, as shown in Fig. 3.

2.2 Experiment Design

The experiment was a within-group design, all participants were tested the two experimental materials. The independent variables in this research were user interface designed based on UCD and EID method in complex electronics manufacturing systems. The dependent variable was measured in NASA-TLX questionnaire. We used the NASA-TLX questionnaire for measuring user subjective workload. The questionnaire for NASA-TLX was designed to assess user’s subjective workload assessments on operators working with the user interface. NASA-TLX is a multi-dimensional rating procedure that derives an overall workload score based on a weighted average of ratings on six subscales. These subscales include mental demands, physical demands, temporal demands, performance, effort and frustration, as shown in Fig. 4.

2.3 Material

As the experimental material in this research, we chose the user interface of the LED chip high-speed detection and sorting system, which could provide LED chip testing and sorting functions. Two prototypes of the user interface were designed based on the EID and UCD which is undergoing compare evaluation the subjective workload. Using the simulator technology, the materials were shown in a 19 inches LCD Monitor (16:10, 1440 * 900 pixels), as shown in Figs. 5 and 6.

2.4 Participants

A total of 45 operators at Guangdong Zhicheng-Huake Optoelectronic Equipment Co. Ltd. were randomly selected to participate in this experiment, 22 male and 23 female, aged 20–25 (Mean age = 22.13, SD = 1.75) which female of subjects accounted for 51%, male subjects were 49%.

2.5 Procedure

Firstly, participants were asked to read the introduction of the experiment requirements, then signatures in the “Experimental Consent”. Test environment was a quiet LED laboratory without interference and noise. Participants were instructed to switch off their mobile phones to reduce possible distractions during the experiment. Next, participants read a short guide manual about the experiment material to insure they were able to understand and solve the given task. When the participant was ready, we started the experiment. Participants were asked to operate on the experimental material for the given task. The duration of each task was 2–3 min based on the task. After each of the experiment task, participants were asked to complete the NASA-TLX questionnaire immediately. The questionnaire answers were manually recorded by the operator. A total of 90 questionnaires were collected after the experiment (45 participants *2 tasks).

3 Results and Discussion

Using IBM SPSS Statistics 19 analysis, the results were as follows:

3.1 The Reliability Analysis

The cronbach’s alpha = 0.941, displays the scale of the each project has high internal consistency. Furthermore, mean of mental demands in UCD is 5.58 (Std. Deviation = 1.20), mean of mental demands in EID is 2.62 (Std. Deviation = 1.59). Mean of physical demands in UCD is 5.64 (Std. Deviation = 0.98), mean of physical demands in EID is 2.84 (Std. Deviation = 1.41). Mean of temporal demands in UCD is 5.64 (Std. Deviation = 1.19), mean of temporal demands in EID is 2.93 (Std. Deviation = 1.19). Mean of performance in UCD is 5.44 (Std. Deviation = 1.20), mean of performance in EID is 2.26 (Std. Deviation = 1.08). Mean of effort in UCD is 5.58 (Std. Deviation = 1.08), mean of effort in EID is 2.73 (Std. Deviation = 1.19). Mean of frustration in UCD is 5.42 (Std. Deviation = 1.23), mean of frustration in EID is 2.64 (Std. Deviation = 1.35), as shown in Fig. 7.

3.2 The ANOVA Analysis

The results showed that the subjective workload rating of material A was significantly higher than material B. It has significant difference subjective workload rating between material A and B, subscales include mental demands (P < 0.05), physical demands (P < 0.05), temporal demands (P < 0.05), performance (P < 0.05), effort (P < 0.05) and frustration (P < 0.05), as shown in Table 1 and Fig. 8.

4 Conclusions

Although a number of theories and principles have been developed to guide the EID and UCD, it is not always apparent how to apply the knowledge in these principles. We describe the application of EID and UCD for the analysis of the differences. General principles from EID are outlined and then applied to the analysis of the user interface design. This study provided a useful framework for analysis of the EID methods, and provided insights into the strengths and weaknesses of various aspects of EID and UCD.

The main findings of this study were as follows: (1) we found that the ecological interface design and user-centered design had significant differences in each levels; (2) the ecological interface design has a significant better effect on subjective workload compare to user-centered design in the complex electronics manufacturing systems (P < 0.05).

However, the limitations of this research should be discussed. (a) The participants: the participants were all from the same company, so they might have a partiality for this study. In would be beneficial to include a wider range of participation in future research. (b) The experimental materials: we only studied user interface in LED chip high-speed detection and sorting system; future research could use more types of user interfaces. Although this study has its limitation, we hope that it can serve as a basis for future studies.

References

ISO, TSISO: 9241–210, Ergonomics of System Interaction-Part 210: Human-centered design for interactive systems. International Organization for Standardization (2010)

Burns, C.M., Hajdukiewicz, J.: Ecological Interface Design. CRC Press, Boca Raton (2013)

Eason, K.: Afterword: the past, present and future of sociotechnical systems theory. Appl. Ergon. 2(45), 213–220 (2014)

Vicente, K.J., Rasmussen, J.: Ecological interface design: theoretical foundations. IEEE Trans. Syst. Man Cybern. 22(4), 589–606 (1992)

Vicente, K.J.: Ecological interface design: supporting operator adaptation, continuous learning, distributed, collaborative work. In: Proceedings of the Human Centered Processes Conference, pp. 93–97 (1999b)

Upton, C., Doherty, G.: Extending ecological interface design principles: a manufacturing case study. Int. J. Hum. Comput. Stud. 66(4), 271–286 (2008)

Endsley, M.R.: Designing for Situation Awareness: An Approach to User-Centered Design. CRC Press, Boca Raton (2011)

Hajdukiewicz, J., Burns, C.: Strategies for bridging the gap between analysis and design for ecological interface design. In: Proceedings of the Human Factors and Ergonomics Society Annual Meeting, vol. 48(3), pp. 479–483. SAGE Publications (2004)

Maguire, M.: Methods to support human-centred design. Int. J. Hum. Comput. Stud. 55(4), 587–634 (2001)

Gulliksen, J., et al.: Key principles for user-centred systems design. Behav. Inf. Technol. 22(6), 397–409 (2003)

Carayon, P.: Human factors of complex sociotechnical systems. Appl. Ergon. 37(4), 525–535 (2006)

Vicente, K.J.: Ecological interface design: progress and challenges. Hum. Factors: J. Hum. Factors Ergon. Soc. 44(1), 62–78 (2002)

Acknowledgments

The research financial supports from the Fundamental Research Funds for the Central Universities HUST: (2014QN017). This paper is also supported by the high-level international curriculum projects of HUST.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this paper

Cite this paper

Wu, L., Li, J., Lei, T., Li, B. (2016). EID vs UCD: A Comparative Study on User Interface Design in Complex Electronics Manufacturing Systems. In: Harris, D. (eds) Engineering Psychology and Cognitive Ergonomics. EPCE 2016. Lecture Notes in Computer Science(), vol 9736. Springer, Cham. https://doi.org/10.1007/978-3-319-40030-3_35

Download citation

DOI: https://doi.org/10.1007/978-3-319-40030-3_35

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-40029-7

Online ISBN: 978-3-319-40030-3

eBook Packages: Computer ScienceComputer Science (R0)