Abstract

One of the main prerequisites in finger vein research is the availability of comprehensive, available finger vein datasets. In order to capture such datasets, a biometric scanner device tailored to capture the vascular patterns is essential. A sophisticated scanner design is the key to achieve a good image quality, robustness against external influences and finally to arrive at a competitive recognition performance. In this chapter, a fully open-source, modular and multipurpose finger vein scanner design is proposed. Two novel finger vein scanners are derived from this basic design. Both are able to capture reflected light and light transmission illuminated images from the dorsal as well as the palmar side. Three fingers are captured at once. The first scanner is based on widely used near-infrared LEDs as its light source, the second one on near-infrared laser modules. Despite their advantages in touchless operation, near-infrared laser modules have hardly been used in finger vein recognition so far. Our scanner design has proven to accomplish an excellent recognition performance using common finger vein recognition schemes. All details regarding the two scanner devices, including technical drawings of all parts, models of the 3D printed parts, control board schematics, the microcontroller firmware, the capturing software, parts list as well as assembly and setup instructions, are available free of charge for research purposes. This should facilitate interested researchers to rebuild such a scanner device for capturing finger vein data on their own.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

- Finger vein scanner

- Open-source biometric sensor device

- Light transmission

- Reflected light

- Open finger vein dataset

- Dorsal

- Palmar

- Scanner assembly details

1 Introduction

Vascular pattern based biometrics, as a new and emerging biometric trait, deals with the patterns formed by the blood vessels located inside the human body, i.e. it is an internal biometric trait. These vascular patterns are not visible to the naked eye, thus a specifically designed capturing device, usually denoted as biometric scanner or biometric sensor, is necessary to sample this biometric [16]. The haemoglobin contained in the blood flowing through the vessels has a higher light absorption coefficient within the near-infrared (NIR) spectrum than the surrounding tissue. Hence, the vascular patterns can be rendered visible as dark lines in the captured images with the help of NIR illumination and NIR-sensitive cameras but not by using commodity off-the-shelf digital cameras as they usually have a built-in NIR blocking filter. The most common body parts considered include fingers [7, 27, 28, 32, 39], hands [6, 8, 36, 37, 42] and also wrists [21]. In the following, we will focus on the recognition of vascular patterns inside the human fingers, commonly denoted as finger vein recognition.

Finger vein scanner devices are already equipped in commercial products, like automated teller machines (ATMs) in Japan [10], for authentication of bank customers in Poland [9], for securing online banking transactions at home in the UK [29] and as an alternative to fingerprint-based authentication systems in general. Almost all commercial-off-the-shelf (COTS) finger vein scanner devices do not permit access to the captured finger vein images. Instead, they only provide a biometric template, encoded in a proprietary format defined by the manufacturer of the scanner device, which can only be used within the software framework provided by the manufacturer. This situation leads to a vendor lock-in, which is not desired for the operator. Moreover, it makes recognition performance evaluations possible, but these biometric templates do neither allow for the development of biometric template protection and biometric workload reduction schemes (see Chap. 12) nor enable a systematic evaluation of the template’s properties in regards to external influences and changes in the vein pattern (robustness evaluation). Hence, these templates and the COTS scanners are only of little use in biometric research.

An important requirement for doing research on any biometric trait is the availability of comprehensive datasets. However, the number of finger vein datasets available to the research community is limited and there is still a lack of large, available finger vein databases. In order to establish a dataset that is of value for research purposes, a finger vein scanner that provides access to the raw vein images is essential. The design of such a scanner device is a crucial point if it comes to image quality, robustness against external influences, user convenience and consequently to a good recognition performance. Only a specifically designed finger vein scanner is able to provide high-quality vein images enabling a competitive recognition performance. The main contribution of this chapter is our proposed design of two open-source, multipurpose finger vein scanners. Both scanners are based on the same modular design. They are one of the first finger vein scanners (besides the scanner proposed by Raghavendra et al. in [26]) that are able to capture three fingers at once in order to speed up the data acquisition process and to minimise longitudinal pose variations (see [23] for an in-depth discussion of the problems due to longitudinal finger rotation). Both are equipped with a light transmission (also called transillumination) as well as a reflected light illuminator allowing to capture light transmission and reflected light images. Hence, these scanners are the first ones that are able to capture both reflected light and light transmission images. Both scanners capture high-resolution and high-quality finger vein images providing a high recognition performance. Furthermore, both of the mainly used views of the finger, dorsal and palmar, can be captured. The two scanners only differ in the type of transillumination light source: the first scanner utilises NIR light-emitting diodes (LEDs) while the second one is based on NIR laser modules. NIR laser modules are not common in finger vein recognition despite the advantages they offer. They enable an increased range of vertical finger movement while preserving a good image contrast and quality compared to LEDs which is especially important if touchless operation is desired.

Our proposed scanner design is fully open source. All of the housing parts and mounting brackets are either 3D-printed or laser-cut plywood parts and can be reproduced with low expenditure. While this chapter covers all the important design key points and describes each of the scanner parts, all technical details of the scanner together with detailed assembly and setup instructions are available in a public repository. This includes part lists, data sheets of the individual parts, technical drawings of the housing parts, models of the 3D printed parts, the schematics and board layout of the illumination controller, the firmware of the illumination controller and the capturing software. By open sourcing all details of our proposed scanner design, other researchers working in the field of finger vein biometrics can benefit from our design. They can get and/or make all the parts needed to construct a finger vein scanner based on our design, follow the instructions and assemble the scanner on their own which enables them to capture high-quality finger vein images and facilitate their own research. The use of our proposed scanner design and the reproduction of the finger vein scanner itself is free of charge for research purposes. The modular design of the scanner allows to exchange, modify and improve the individual parts easily. With the help of other researchers we are confident that our scanner design will continue to improve over time.

The second advantage that comes with a fully open-source scanner design is the ability to establish a large, publicly available finger vein dataset. We already established a finger vein dataset captured using the two scanners based on our design which is available for research purposes [34]. This dataset confirms the decent recognition performance that can be achieved using a scanner based on our design. For more details, see [12, 13]. Together with other researchers and research institutions, we plan to extend this dataset in order to establish a comprehensive, publicly available finger vein dataset for research purposes. Researchers already owning a scanner based on our design and interested in a collaboration can contribute to the dataset by providing us their captured finger vein samples. Such an extensive, collaborative dataset will stimulate the research on finger vein biometrics. Moreover, large finger vein datasets are vital in order to develop and test finger vein indexing schemes, template protection schemes and runtime efficient identification schemes.

The rest of this chapter is organised as follows: Sect. 3.2 gives an overview on the basic design principles of finger vein scanners, followed by a review of commercial finger vein scanners and related research on finger vein scanners as well as datasets. Section 3.3 discusses all important details and individual parts of our proposed finger vein scanner design. Section 3.4 presents our open finger vein dataset captured using the scanners built according to our design. Section 3.5 concludes this chapter together with an outlook on future work, especially on further improving the scanner design and extending our open finger vein dataset.

2 Finger Vein Scanners

Finger vein recognition belongs to vascular pattern based biometrics. As the name suggests, these biometrics are based on the vascular pattern, formed by the blood vessel structure inside the human body. Finger vein recognition deals with the vascular pattern inside the human fingers. This pattern has to be made visible and captured by a suitable biometric scanner device in order to enable biometric recognition. The de-oxinated haemoglobin in the blood flowing through the blood vessels absorbs light within the NIR spectrum while the surrounding tissue has a much lower light absorption coefficient within that spectrum. Thus, the vascular pattern can be rendered visible with the help of an NIR light source in combination with an NIR-sensitive image sensor.

Consequently, the most important parts of a finger vein scanner are an NIR light source and an NIR-sensitive image sensor or camera. The NIR light source usually consists of NIR LEDs (light-emitting diodes) with a light emission peak wavelength between 750 and 950 nm. In addition to the NIR camera and the NIR light source, either an NIR pass-through filter or an optically opaque box to reduce the influence of ambient light is beneficial. To assist the capture subject in positioning of the finger, most finger vein scanners contain some kind of finger positioning support or finger guide unless they are meant for fully touchless operation.

2.1 Light Source Positioning

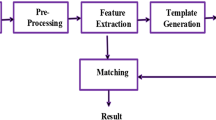

Two types of illumination are distinguished, based on the relative positioning of the image sensor, the finger and the illuminator: light transmission, also called transillumination and reflected light. Figure 3.1 shows both variants.

Light transmission: the image sensor and the illuminator are placed on opposite sides of the finger. The light penetrates the skin on the side of the finger next to the illuminator, runs through the finger tissue, where it gets reflected, refracted, dispersed, scattered and absorbed. A fraction of the emitted light emerges on the opposite side of the finger and gets captured by the image sensor. As the light has to travel through the whole finger, higher light intensities are needed compared to reflected light, thus leading to higher power consumption. Due to the placement of the illuminator and the image sensor opposite to each other, the scanner devices are bigger compared to reflected light ones. Note that the positioning of the image sensor and the illuminator perpendicular to each other (in an angle of \(90^{\circ }\)) is sometimes called light dispersion. We consider this still as light transmission as it is just a kind of light transmission caused due to scattering and refraction. The light travels sideways through the finger and the fraction of the light which is emitted on the image sensor side of the finger gets captured.

Reflected light: the image sensor and the illuminator are placed on the same side of the finger, either dorsal or palmar. The light originates from the illuminator, a small part gets reflected directly at the finger’s surface, the remaining part penetrates the skin and tissue and gets reflected, refracted and scattered there. The fraction of the light emerging at the same side of the finger is captured by the image sensor. Reflected light based scanners need less light intensity. Thus, they have a lower power consumption and can be built in a smaller manner as the light source and image sensor are positioned next to each other. However, the penetration depth of the light is lower than for light transmission, and thus less details of the vascular patterns become visible. Nevertheless, in finger vein recognition, light transmission is used almost exclusively.

2.2 Two Main Perspectives of the Finger—Dorsal and Palmar

The main perspectives or views from which the finger is captured are dorsal and palmar (also called ventral). Dorsal images are taken from the back or dorsal side of the hand while palmar images are taken from the palm or bottom side of the hand. Figure 3.2 shows both capturing perspectives. Of course there are several more views around the finger that could be captured like the side views, but finger vein recognition mainly deals with palmar images, with some exceptions where the dorsal view is used.

2.3 Commercial Finger Vein Scanners

Here we present some common COTS finger vein scanners. As in finger vein recognition, light transmission in combination with palmar images is used almost exclusively, so all COTS scanners are based on this set-up as well (some COTS scanners have the light source and the camera arranged perpendicular to each other which the manufacturers call light dispersion). As motivated in the introduction, the COTS scanners do not provide access to the captured vein images but only output a template encoded in a proprietary format. Figure 3.3 shows some widely used COTS finger vein scanners. The major two companies providing finger vein authentication solutions are Hitachi Ltd. and Mofiria Ltd. Their technologies are patented and non-disclosed. Hence, not many details are known about these scanners, except that they are based on the light transmission principle and capture palmar images. The M2-FingerVein™ reader [52] is basically a rebranded version of the original Hitachi H-1 (or PCT-KCUA011) USB finger vein scanner [51]. According to the M2SYS website, it “scans the inner surface of the finger”, is “resistant to criminal tempering”, achieves a “high accuracy”, “less than \(0.01\%\) for the FRR, less than \(0.0001\%\) for the FAR and \(0\%\) for the FTE”, uses a “unique and constant” biometric trait and provides “fast authentication speed”. However, the scanner design and details are undisclosed making it hard to verify those claims. The scanner provides “fast authentication speed” indeed but especially bearing in mind that this scanner is not able to prevent longitudinal finger rotation [23], the claimed FRR and FAR values are doubtful. Moreover, it has been shown that commercial scanners are susceptible to presentation attacks [30], hence the claim “resistant to criminal tempering” might only refer to tempering with the scanner hardware and authentication software. The Mofiria FVA-U3SX [57] and the FVA-U4ST [58] are based on Mofiria’s “unique reflective dispersion method” and an “automatic finger position adjustment ensures both comfortable usability and high accuracy authentication without firmly fixing the finger position on the unit” according to their respective data sheets. Both are small, fast and comfortable USB-powered finger vein scanners that provide two enrolment methods. The FVA-U3SX has an electrostatic sensor to detect the presence of the finger on the scanner. Note the compact size of all the commercial scanners and the semi- or full-open scanner housing. Scanners built in an open manner have been shown to increase the capture subjects’ acceptance and convenience.

2.4 Finger Vein Prototype Scanners and Datasets in Research

Due to the fact that almost all COTS finger vein scanners do not provide access to the raw finger vein images and that the datasets established by the commercial companies are non-disclosed, researchers began to construct their own finger vein scanners and established several finger vein datasets. Table 3.1 gives an overview of several available as well as unpublished finger vein datasets in chronological order. It lists the number of subjects and fingers per subject that were captured, the total number of images contained in the dataset, the number of capturing sessions, the image resolution and the scanner used to capture the images. The first publicly available finger vein dataset was established by the Peking University (PKU) [11] in 2008 using their own prototype scanner (PKU Proto). The Seoul National University (SNU) [15] established the first non-contact finger vein dataset in 2009. They built their own touchless prototype scanner (SNU Proto). The dataset was captured using two different scanners, an LED and a laser-based one. The Norwegian Biometrics Laboratory collected the GUC45 [5], a multi-modal database comprising finger vein, finger knuckle and fingerprint images using their two prototype scanners (GUC Proto 1 and GUC Proto 2) in 2009. This database is only available semi-publicly, i.e. that visitors at the Norwegian Biometrics Laboratory can access and use the database. The second database established in 2009 is the THU-FVFDT [40] provided by the University of Tsinghua, captured using their self-designed prototype scanner (Tsinghua Proto). It contains finger vein as well as finger dorsal texture images. In 2010, the SDUMLA-HMT [41], a multi-modal biometric database including finger vein images, was released by the University of Shandong. They utilised a custom prototype scanner provided by the University of Wuhan (Wuhan Proto) during their finger vein data collection. In 2011, the HKPU finger vein database [16] captured using their own prototype scanner (HKPU Proto) was released by the Hong Kong Polytechnical University. The KTDeaduk-FV finger vein database [17] was collected by the KT Daeduk Research Center in Korea in cooperation with the Korea Science Academy of KAIST in 2011 too. This database was captured with their own prototype scanner (KTDeaduk Proto). It has not been published so far. The Shandong University acquired a finger vein dataset using their prototype embedded finger vein scanner (Shandong EL Proto). This dataset has not been published though. In 2013, several finger vein databases have been established. The University of Twente published the UTFVP finger vein database [32], captured with the help of their prototype scanner (Twente Proto). The Chonbuk University in South Korea used their prototype scanner (Chonbuk Proto) to establish the MMCBNU_6000 finger vein database [19]. The Shandon University released the CFVD [43], the first reflected light finger vein database acquired using their prototype scanner (Shandong Proto). The Shandong University established a second finger vein database [38] using a prototype scanner provided by the University of Wuhan (Wuhan Proto) but did not make this database available. The FV-USM database [1] published by the University of Sains in Malaysia was acquired using their custom-designed scanner (Sains Proto) and also released in 2013. In 2014, the Idiap Research Institute in Switzerland established the first finger vein spoofing attack database, VERA Finger Vein Spoofing [30] using the same scanner design as it has been used to capture the UTFVP (Twente Proto). The Norwegian Biometrics Laboratory designed another finger vein scanner prototype (GUC-FPFV Proto), able to capture fingerprint and finger vein images at the same time. In 2014, they captured the GUC-FPFV-DB [25] but they did not make it available * in Table 3.1 indicates that for most but not for all subjects 6 fingers have been captured as there are subjects with less than 6 captured fingers. In 2015, the Norwegian Biometrics Laboratory designed another finger vein scanner which captures dorsal images (GUC-Dors Proto) and created the first dorsal finger vein database [24]. Again they did not fully release this database for the research community. It is only semi-public, i.e. available for visitors at the Norwegian Biometrics Laboratory. In 2017, together with our partners from the PROTECT project the team at PLUS (Paris Lodron University of Salzburg) established a multi-modal biometric database PMMDB [33]. Among other biometric traits, this database contains dorsal finger vein images captured with the predecessor of our proposed scanner design (PLUSVein-V2), and is publicly available. Our most recent finger vein database is the PLUSVein-FV3 [12], captured using the scanner design presented in this chapter (PLUS OpenVein). This database is publicly available as well. Note that except the GUC-Dors-FV-DB [24] established by the Norwegian Biometrics Laboratory, the PMMDB-FV [33] and the PLUSVein-FV3 dataset [12], which have been captured by members of PLUS, all finger vein datasets are palmar ones. Figure 3.4 shows some example images for the available finger vein datasets (except for PKU and CFVD). We will not go into further details about the databases but focus on the corresponding scanner devices in the following.

Example images from several available finger vein datasets, left-to-right, top-to-bottom row (all images have been rotated such that the finger is in vertical position pointing upwards): PMMDB-FV, UTFVP, MMCBNU_6000, FV-USM, THU-FVFDT, VERA FV-Spoofing, HKPU-FID, SDUMLA-HMT, PLUSVein-FV3 dorsal, PLUSVein-FV3 palmar

Table 3.2 gives some details about the scanners that were used to acquire the finger vein databases listed in Table 3.1, including the equipped camera, focal length of the lens (column: lens), additional filter, the illuminator peak wavelength (column: illumin., note that all illuminators except the one of the SNU Proto, the Shandong EL Proto and the PLUS OpenVein are LED based) as well as if the illuminator is a reflected light or light transmission type (column: r/t) as far as the information is available for the respective finger vein scanner device (– in the table indicates that this information is not available). All of the listed finger vein scanners except the Shandong Proto and our proposed scanner PLUS OpenVein (which is able to use both reflected light as well as light transmission) use light transmission to capture the images. The PKU Proto scanner consists of a 1/3-in. greyscale CMOS camera and an advanced illumination control system using an LED-based illuminator. Apart from those details there is no additional information about the camera, the LEDs or the equipped infrared filter available. There are two variants of the touchless scanner prototype developed by the Seoul National University, SNU Proto. This touchless scanner should prevent the cross-contamination of skin diseases. The first one is based on conventional 850 nm LEDs as light source, the second one is based on an 830 nm NIR laser. The NIR lasers are manufactured by Lasiris Laser in StokerYale, Canada. A laser line generator lens (E43-475 from Edmund optics in Singapore) with a fixed pan angle is added in order to generate a line laser from the spot laser. This should enable a uniform illumination along the finger. Both scanners are based on light transmission and use a GF 038B NIR CCD Camera from ALLIED Vision Technologies, Germany. The camera is equipped with an additional IR-pass filter. The first two scanner prototypes developed by the Norwegian Biometrics Laboratory in 2009, GUC Proto 1 and GUC Proto 2 both use a CCD camera in combination with an NIR-pass filter. 850 nm LEDs and 940 nm LEDs are used in the first and second scanners, respectively. Besides this basic information, also the arrangement of the LEDs, their view range and the physical design of the scanners are described in the respective papers. The Tsinghua Proto uses two arrays of 890 nm LEDs, one mounted above the top-left and the other one above the top-right of the finger. It has two cameras, one located at the bottom of the device (below the finger), equipped with an IR filter with a cut-off wavelength of 1000 nm to capture the finger vein images and another camera situated on the top of the device (above the finger) to capture the dorsal texture images. The Wuhan Proto scanner is based on a near-infrared CCD camera including an additional NIR-pass filter with a wavelength of 900 nm. The light source consists of 790 nm LEDs. The scanner device has a groove in the shell of the device used to guide the finger’s orientation. No detailed information about the camera and the illumination control is available. The HKU Proto scanner exposes the dorsal side to NIR frontal illuminators consisting of LEDs with a peak wavelength of 850 nm. It has two cameras, an NIR camera in combination with an NIR filter to capture the vein images and one webcam to capture the finger texture. It does neither use a finger guide nor pegs to align the finger, so it can be regarded as semi-touchless device. Again, there are no details about the specific type of camera, LEDs or NIR filter available. The KTDaeduk Proto scanner is equipped with a CCD camera, including an additional NIR passing filter with a cut-off wavelength of 750 nm, located at the bottom of the device. A hot mirror is used to be able to mount the camera horizontally, and thus to reduce the height of the device. The NIR illuminator is located at the top of the device, above the dorsal side of the finger, and based on 850 nm LEDs. In addition, the scanner has a finger guidance to assist the capture subject in positioning his finger correctly. The Shandong EL Proto is the main part of an embedded finger vein recognition system. It is based on the light transmission principle but uses three NIR laser diodes with a peak wavelength of 808 nm instead of LEDs due to their stronger permeability and higher optical output power compared to LEDs. The scanner is equipped with a monochromatic NIR camera and an additional NIR-pass filter with a cut-off frequency of 800 nm to block daylight. A plate of 10 mm thick, transparent acryl is located above the NIR laser diodes to serve as a platform for positioning the finger and to remove uneven illumination. The whole scanner/finger vein recognition system is controlled by a DSP based mainboard. The Twente Proto is the best documented scanner so far. Its light source consists of 8 Osram SFH4550 LEDs (the same type we use for the reflected light illuminator) with a peak wavelength of 850 nm, situated on top of the dorsal side of the finger. Each LED is intensity controlled individually by a simple control loop to achieve a uniform illumination intensity along the finger. The camera is a C-Cam BCi5 monochrome CMOS camera, fitted with a Pentax H1214-M machine vision lens having a focal length of 12 mm. An additional infrared filter with a cut-off wavelength of 930 nm (type B+W 093) is mounted on the lens. The scanner device uses an Edmund Optics NT41-405 first surface mirror to minimise the height of the scanner. However, this scanner device is still quite bulky. Detailed information about the scanner design can be found in the Master’s thesis of Ton [31]; however, based solely on the published details it is not possible to construct a ready-to-use scanner in a straightforward way. The Twente Proto scanner is described in Chap. 5 [35] of this book. Section 6 of Chap. 5 [35] also presents a novel finger vein acquisition device proposed by the University of Twente. This new version of the scanner is much more compact compared to the Twente Proto one. It is based on a Raspberry Pi as processing board and three Raspberry Pi camera modules as image sensors. It consists of three NIR LED strips that can be positioned in a semicircle from 0–180\(^{\circ }\). Thus, this scanner is able to capture multi-perspective finger vein images (cgf. Chap. 13 [22]) and allows for 3D finger vein reconstruction. The team at the University of Twente is currently investigating the optimal illumination and settings for the 3D finger vein reconstruction. The Chonbuk Proto scanner is equipped with a camera including an additional infrared light passing filter and an array of 850 nm infrared LEDs located above the finger. The camera is a modified COTS camera where the NIR blocking filter was replaced by an NIR pass-through filter. It has a finger holder with a hole in the backside of the scanner serving as a finger placement unit. This prototype scanner is quite small with a size of \(68\times 54\times 101\) mm. The Shandong Proto is the only scanner prototype besides out PLUS OpenVein scanner that is based on reflected light. It consists of a camera, an NIR pass-through filter with a cut-off wavelength of 850 nm and an NIR light source based on 850 nm LEDs. This is the only information that is available for this prototype scanner. The Sains Proto scanner has three units of 850 nm NIR LEDs, placed in a row on the top section of the scanner, serving as light source. A Sony PSEye camera is mounted at the bottom section of the scanner. It does not use any pegs or finger guides. The capture subject has to touch the back wall of the scanner with their finger only. The GUC-FPFV Proto scanner is able to capture finger vein and fingerprint images at once. It is designed to be a low-cost device, consisting of a DMK 22BUC03 monochrome CMOS camera, fitted with a T3Z0312CS 8 mm lens and an LED-based illuminator made of 40 Vishey Semiconductors TSSF5210 870 nm NIR LEDs. The scanners have additional physical structures made of aluminium foil to channel and focus the luminous flux in order to provide enough light intensity to penetrate the whole finger. The scanner device has a size of \(180\times 110\times 70\) mm. The GUC-Dors Proto scanner is designed to capture dorsal finger vein images. It uses the same camera and lens as the GUC-FPFV Proto (DMK 22BUC03 monochrome CMOS camera, fitted with a T3Z0312CS 8 mm lens) but 920 nm LEDs instead of 850 nm ones. The light source is placed 10 mm away from the finger placement holder and the camera is placed 100 mm away from the finger. This is the only information available about that scanner, not even an image is depicted in the paper. The PLUSVein-V2 scanner is also designed to capture dorsal finger vein images but could be easily used to capture palmar images as well. It is based on an IDS Imaging UI-ML-1240NIR NIR-enhanced industrial camera fitted with a Fujifilm HF9HA-1B 9 mm lens (the same as in our design of the PLUS OpenVein scanner ). No additional NIR pass-through filter is used, instead the scanner is embedded in a wooden box to block the ambient light. The light transmission illuminator consists of 8 Osram SFH 4253-Z 850 nm LEDs. Each LED is brightness controlled individually by an automatic brightness control algorithm in order to achieve an optimal illumination along the finger.

For most of the above-mentioned finger vein scanner prototypes, except the Twente Proto, only very few details are available. Thus, it is not possible to reproduce those scanners in a straightforward manner. Our PLUS OpenVein scanner is the first finger vein scanner that is able to capture both reflected light and light transmission images. Moreover, it is designed to capture dorsal as well as palmar images. Most important though: its design is fully open source. Our scanner design is explained in detail in the following section.

3 PLUS OpenVein Finger Vein Scanner

This section presents our proposed, fully open-source finger vein scanner design, called PLUS OpenVein. At first, the advantages of our scanner design and the differences to existing finger vein scanners are discussed, followed by a detailed explanation of the individual scanner parts. The finger vein scanner design consists of the following main components: an NIR-enhanced camera together with a lens and an NIR pass-through filter, an NIR light transmission illuminator including an illuminator bracket, an NIR reflected light illuminator, an illuminator control board, a finger placement unit and a modular wooden housing. The functional interaction of each of the individual scanner parts, specified by the scanner design, is as important as the choice of each of the individual parts in order to achieve a good finger vein image quality, and consequently a high recognition performance.

3.1 Advantages and Differences to Existing Designs

The following list summarises the main advantages and differences of the proposed design over the existing ones presented in Sect. 3.2.4:

-

Modular and easy to reproduce design: Most finger vein scanners in research do not place any importance on enabling changes of their individual parts. The PLUS OpenVein is a modular finger vein scanner design, i.e. its individual parts can be replaced, modified and improved easily. All of the housing parts and mounting brackets are either 3D-printed or laser-cut plywood parts. One the one hand, this enables each researcher owning a 3D printer to reproduce the scanner (the laser-cut parts can also be reproduced using a jigsaw). On the other hand, it is easy to modify and improve those parts to individual needs as only the 3D models have to be edited.

-

Dorsal/palmar images as well as light transmission/reflected light: although it is easy to capture dorsal images using a scanner meant to capture palmar ones by simply turning the finger around, it is hard to maintain the same longitudinal rotation angle at each capture. Moreover, all exisiting finger vein scanner designs exhibit either light transmission or reflected light only. Our finger vein scanner design is a multipurpose one as it is able to capture dorsal as well as palmar (by rotating the hand \(180^{\circ }\) around its longitudinal axis), with the finger placement unit especially shaped to prevent unwanted longitudinal finger rotation [23] and achieve a defined finger position for each image capture. Furthermore, it is equipped with two types of illuminators, a light transmission as well as a reflected light one, to acquire palmar and dorsal finger vein images during a single acquisition.

-

Three fingers are captured simultaneously: All COTS scanners as well as all research prototype scanners listed in Table 3.2 capture only one finger at a time. The PLUS OpenVein scanner design is the first proposed finger vein scanner that is designed to capture three fingers (index, middle and ring finger) at once to speed up the data acquisition process.

-

NIR laser module based scanner version: NIR laser modules exhibit several advantages over NIR LEDs, especially in contactless operation as described in Sect. 3.3.3.2. However, all COTS finger vein scanners as well as the majority of scanners used in research are based on NIR LEDs. We derived two versions of our PLUS OpenVein finger vein scanner design, one is based on a standard NIR LED light transmission illuminator while the second one is based on an NIR laser module illuminator. Both scanners are derived from the same basic structure and differ only in their illuminator, the illuminator control board and the illuminator bracket.

-

Finger placement unit to prevent finger misplacement: In [23], we showed that longitudinal finger rotation can easily occur with most types of finger vein scanners and has a severe impact on the recognition performance too. Bearing that in mind, we designed our finger placement unit to prevent most possible kinds of finger misplacements, especially longitudinal finger rotation. This finger placement unit is described in Sect. 3.3.6.

-

Open-source scanner design: As mentioned in Sect. 3.2.4, not many details are available for most of the finger vein scanner designs in research, apart from a few exceptions (e.g. the design of Ton [31]). Our scanner design is the first true open-source one. All technical details of the scanner parts, the data sheets, the software as well as more detailed descriptions and instructions for constructing and setting up the scanner can be found in our public repository: http://www.wavelab.at/sources/PLUS-OpenVein, making it a fully open-source scanner design. Our license agreement permits the free of charge use, modifications and reproduction finger vein scanners based on our design for research and non-profit purposes.

-

The main disadvantage of our scanner design is its higher price compared to other designs which are based on low-cost camera modules, like the new Twente Proto [35], the GUC-FPFV Proto [25], the GUC-Dors Proto [24] and the one proposed in [26]. On the one hand, the high-quality industrial NIR enhanced camera allows for a higher image quality and contrast compared to the low-cost cameras. On the other hand, the camera module can be easily replaced by any other suitable camera module thanks to our modular design, effectively reducing the total costs of the scanner device to the same level as other low-cost scanner devices. Hence, in practice, this is not really a disadvantage.

Figure 3.5 shows both of the scanners fully assembled and with the right and front side of the scanner half open including labelled parts. The outside dimensions of the LED version and the laser module based scanner are \(146\times 175\times 258\) mm and \(146\times 175\times 306\) mm, respectively. Each individual scanner part together with its advantages over similar designs and the design decisions is explained in the following.

3.2 Image Sensor, Lens and Additional Filter

The IDS Imaging UI-ML1240-NIR camera [60] was chosen as image sensor. It has a max. resolution of \(1280\times 1024\) pixels and a max. frame rate of 25 fps. It is based on the EV76C661ABT CMOS monochrome image sensor, having a colour depth of 8 bit, a max. resolution of 1.31 megapixels, with a pixel size of 5.3 µm and a sensor diagonal of 1/1.84 in. The main advantage of this camera compared to modified webcams and other visible light cameras is that it is an NIR-enhanced industrial camera. It is specifically designed to achieve a high quantum efficiency within the NIR spectrum. Note the higher quantum efficiency within 800–900 nm of the NIR version compared to the monochrome one, both depicted in Fig. 3.6 left. This wavelength range includes the peak wavelengths of our NIR LEDs (850 nm) and NIR laser modules (808 nm) equipped in the light transmission illuminator. Most COTS and consumer cameras that are designed for the visible wavelength spectrum are sensitive in the NIR spectrum too, but they are equipped with NIR blocking filters in order to avoid unwanted colour effects caused by NIR light (the sunlight contains an NIR wavelength spectrum part too which would stain the images blue to violet). The NIR blocking filter can be removed, enabling the camera to capture NIR images, but those modified cameras are less sensitive than a special NIR-enhanced camera. Due to its increased NIR sensitivity, an NIR-enhanced camera achieves a higher image contrast in the NIR spectrum than a visible wavelength one. On the contrary, a special NIR-enhanced industrial camera is several orders of magnitude more expensive than a modified webcam solution, posing a disadvantage for this type of camera in terms of costs. However, advantages in terms of image quality predominated, and thus the use of an NIR-enhanced camera was the preferred option for our finger vein scanner design. Note that the camera holder bracket can be modified for the use of different camera models easily.

Left: quantum efficiency charts for the UI-ML-1240-NIR (black line) and the UI-ML-1240-M (purple line), taken from the data sheet [60], right: filter chart for the MIDOPT FIL LP780/27 (solid red line) and LP830/27 (dashed blue line) NIR pass-through filter

The camera is equipped with a Fujifilm HF9HA-1B 9 mm fixed focal lens [50]. The lens has a manual iris and is C-Mount compatible. The short focal length of 9 mm is necessary to maintain a short distance between the camera and the finger which is desired in order to reduce the overall size of the scanner device. A lens with an increased focal length has less image distortions but requires a larger distance from the finger, thus increasing the overall size of the scanner. A shorter focal length reduces the minimum distance to the finger but increases the image distortions, especially at the image boundaries. Thus, we decided to use a 9 mm focal length as the best trade-off between the distance to the finger, i.e. the overall scanner dimensions, and the image distortions introduced by the lens itself. A MIDOPT FIL LP830/27 [56] and a MIDOPT FIL LP780/27 [55] NIR pass-through filter for the LED and the laser-based version of the scanner, respectively, are mounted on top of the lens. The filter chart of the LP830, depicted in Fig. 3.6 right as dashed blue line, fits well with the emission spectrum (cf. Fig. 3.9) of the NIR LEDs (peak wavelength of 860 nm) and the filter chart of the LP780 (solid red line in Fig. 3.6) fits well with the NIR laser modules (peak wavelength of 808 nm). This additional NIR pass-through filter helps to reduce the influence of ambient light and further improves the quality of the vein images. Currently, the wooden scanner housing is still needed for stability reasons, to comply with safety regulations for the laser-based version of the scanner and to further reduce the influence of the ambient light in case of direct sunlight shining on the scanner. For the next, slightly improved version of the scanner design, the NIR pass-through filters will be replaced by the MIDOPT BN850 Narrow Near-IR Bandpass Filter [54] and the MIDOPT BN810 Narrow Near-IR Bandpass Filter [53] for the LED version of the scanner and the laser module version of the scanner, respectively. These filters are more effective in reducing the ambient light’s influence and enable the removal of the wooden scanner housing without impacting the image quality for indoor use of the scanner and at least a reduction of the housing’s side plates dimensions if outdoor use is desired. On the other hand, the NIR pass-through filter increases the total costs of the scanner, especially the narrow bandpass filter. If the scanner is used in indoor environments only, where the influence of ambient light can be controlled, it is possible to refrain from using and NIR pass-through filter for cost reasons. To achieve an optimal image quality, we recommend to use the additional NIR pass-through filter though.

The last part of the camera assembly is the camera holder bracket, depicted in Fig. 3.7 together with the camera, the lens and the NIR pass-through filter, which is mounted on the very top of the scanner. The camera holder bracket is again a custom-developed, 3D-printed part which can be easily modified for mounting different cameras.

3.3 Light Transmission Illuminator

There are two different versions of the light transmission illuminator: one based on NIR LEDs and the other one based on NIR laser modules. The scanner equipped with the laser modules is bigger due to the larger size of the laser module based illuminator compared to the LED-based one and due to the minimal distance of about 30 mm between the laser modules and the finger surface which is necessary to adjust the optimal focal length of the laser modules. Both illuminators consist of three stripes, one stripe underneath each finger. These stripes are mounted with the help of a custom-developed, 3D-printed, illuminator bracket, depicted in Fig. 3.8 top for the LED version (the two parts are then screwed together to hold the LEDs in place) and Fig. 3.8 bottom for the laser module based version. This bracket is located underneath the finger placement unit.

3.3.1 LED-Based Version

The LED-based light transmission illuminator has three stripes consisting of 8 Osram SFH-4253-Z SMD LEDs [65] each. The stripes are depicted in Fig. 3.8 top-right. The LEDs have a radiation half-angle of \(\pm 60^{\circ }\), a peak wavelength of 860 nm and a max. radiant intensity of 13 mW/sr. The emission spectrum of the LEDs is depicted in Fig. 3.9 left. These LEDs were chosen as their peak wavelength is within the recommended wavelength band for vascular pattern recognition and because they are standard, low-cost electronic components. They are placed in a distance of 7.5 mm next to each other, which has been determined to be the optimal distance during our tests in order to provide a sufficient and uniform illumination along the finger. Each LED can be brightness controlled separately and independently from the other LEDs in order to achieve an optimal image contrast. The health and safety requirements for NIR LEDs are defined in the IEC-62471 standard on “Photobiological safety of lamps and lamp systems” [3]. The standard defines limits in terms of radiation intensity and duration to prevent Corneal Hazard as well as Retinal Thermal Hazard. The Renesas Electronics application note AN1737 [67] shows an example calculation for an LED similar to the ones equipped in our scanner design, a distance of the LED and eyes of 200 mm and a radiation duration of 10 s. In this case, the safety factor for the Corneal and the Retinal Thermal Hazard is \(4\times 10^{6}\) and \(2\times 10^{5}\), respectively, i.e. the radiation level is at least \(10^{5}\) times below the critical limit. Moreover, our scanner housing prevents any direct exposure of the eye to the LED radiation. Hence, our scanner complies with the health and safety regulations.

Emission spectrum of the light transmission illuminator NIR LEDs (left) and the NIR laser modules (right), taken from the data sheet [65]

3.3.2 Laser Module Based Version

The second version of the light transmission illuminator is based on laser modules instead of LEDs and consists of three stripes of five laser diodes [46] including an adjustable constant-current laser diode driver PCB [45] and a TO-18 housing with a focus adjustable lens [44] for each of the laser modules (the combination of laser diode + control PCB + housing is denoted as laser module or laser). The laser diodes are TO-18 type (diameter 5.6 mm), and have a peak wavelength of 808 nm and an optical output power of 300 mW. These laser diodes belong to Class 3B according to the IEC 60825-1 standard [4]. The guidelines on laser health and safety require that any direct exposure to the laser beam has to be avoided for this laser class. To be compliant with these regulations, the housing of the scanner design is built in a way to ensure that no exposure of the eyes to the laser beam is possible. The emission spectrum of the laser diodes can be seen in Fig. 3.9 right. Note that their emission spectrum is narrower than the spectrum of the LEDs facilitating the use of narrow bandpass filters instead of NIR longpass filters, leading to further attenuation of the ambient light. The main advantages of the laser diodes/laser modules over the LEDs are their higher optical output power and their narrow radiation half-angle. This enables a higher degree of vertical finger movement without degrading the image quality, which is especially important if a full touchless operation is desired. The broad radiation half-angle of the LEDs leads to over-illuminated areas at the finger outline while the contrast in the vein regions is decreased as soon as the finger is not placed directly on top of the illuminator. Due to the narrow radiation half-angle of the laser modules (note that the laser diodes itself do not have such a narrow radiation angle, instead the focus adjustable lens included in the housing makes such a narrow angle possible), the main part of the luminous flux stays inside the centre regions of the finger (where most of the veins are) and thus the contrast in these regions remains stable if the finger is moved upwards (away from the illuminator). Figure 3.10 shows a comparison between the LED (left) and the laser module (right) based scanner. It can be clearly seen that for the LED version the contrast gets lower the further away the finger is from the illuminator while it remains high for the laser module based version. The disadvantage of using laser modules instead of LEDs is their high price. A single laser module is about 15–20 times more expensive than a single LED. In non-contactless operation, the image quality of the laser modules is only slightly better compared to LEDs. Hence, for the current version of the scanner, we recommend the LED-based version to cut down costs. If the scanner design is adopted towards a touchless version, laser modules are the preferred option.

Finger vein images captured with our scanners showing illumination issues due to vertical finger movement (0, 20 and 40 mm away from the scanner surface): note the bright areas along the finger boundaries and the reduced contrast of the vein region the further away the finger gets from the scanner surface for the LED scanner images (left) compared to the laser scanner ones (right) (image originally published in [12], © 2018 IEEE)

3.4 Reflected Light Illuminator

The reflected light illuminator is composed of three different types of LEDs, 850 nm (Osram SFH 4550 LEDs [66] with a radiation half-angle of \(\pm 3^{\circ }\) and a max. radiant intensity of 700 mW/sr), 950 nm (Vishay Semiconductors CQY 99 [69] with a radiation half-angle of \(\pm 22^{\circ }\) and a max. radiant intensity of 35 mW/sr) and warm white daylight ones (Luckylight 504WC2E-W6-3PC [61] with a radiation half-angle of \(\pm 15^{\circ }\) and a typical luminous intensity of 23000 mcd), eight pieces each. These three types of LEDs are all standard, low-cost electronic parts. The two NIR types have peak wavelengths that are within the recommended spectrum for vascular pattern recognition and the warm white daylight one is commonly used in many different applications. The LEDs are mounted in a circle on the reflected light illuminator bracket (depictedn in Fig. 3.11), situated on top of the scanner device around the camera lens. The LEDs are arranged in an alternating manner, i.e. each 850 nm LED is followed by a 950 nm one, then a warm white one, then a 850 nm one and so on. This design turned out to be optimal in terms of uniform illumination regardless which of the three illuminators is turned on. Each of the 850 nm and the 950 nm eight tuples of LEDs can be brightness controlled separately, but not each individual LED. The warm white daylight LEDs can only be turned on at a fixed intensity (no brightness control). The reflected light illuminator enables the capturing of reflected light finger vein images. The warm white daylight LEDs are mainly meant for use during adjusting and testing and not during finger vein image acquisition. However, they can be utilised to capture additional finger texture images.

3.5 Illuminator Brightness Control Board

Figure 3.12 (left: LED version, right: laser module version) shows an image of the first prototype brightness control PCB board built using THT (through-hole-technology) parts. The final version is based on SMD (surface-mounted device) parts. Its two main components are an Arduino Nano board [48] and a Texas Instruments TLC59401/TLC5940PWP [68] (the THT version of the board uses the old version, the TLC5940). The Arduino Nano is a complete, breadboard-friendly microcontroller development board based on the Microchip ATmega328P microcontroller [63], including an integrated USB to UART converter and several external components necessary to operate the ATmega328P. The ATmega328P offers several built-in components, like analog and digital outputs, timers, UART, I2C, SPI Interface, etc. Most important for our application are the six PWM outputs and the UART interface. More details on the ATmega328P can be found in the data sheet [62]. The Texas Instruments TLC5940 is an integrated 16-channel LED driver with dot correction and greyscale PWM control enabling a convenient brightness control of LEDs without the need for external components like dropping resistors. Each output can be controlled separately (4096 steps) and has a drive capability of 120 mA. It operates as a constant-current sink and the desired current can be set using only one external resistor. It is controlled using a serial data interface. As every single LED of the three stripes of eight LEDs each (24 LEDs in total) is desired to be controlled individually, two of these TLC5940 are equipped on the LED version of the control board as each TLC5940 has 16 outputs. In Fig. 3.13, a schematic overview of the control board is depicted. The control board is connected to the PC over the USB interface. The data sent over USB is converted to UART compatible data, received by the Arduino Nano (or the ATmega328P to be precise) which controls the 2 TLC5940s. Each output of the TLC5940 is directly connected to an LED. The LED and the laser module version differ. The laser modules exhibit a higher current consumption than the LEDs that would exceed the maximum of 120 mA provided by the TLC5940. Thus, external PNP transistors (CDIL BC327-25 [49] for the THT version of the board and ON Semiconductor BC808-25 SMD [64] for the final SMD version) in combination with suitable base dropping resistors are added. The laser modules are not directly connected to the TLC5940 but to the PNP transistors. The laser module version has only one TLC5940 as there are 15 laser modules in total (compared to the LED version with 24 LEDs). Furthermore, two of the PWM outputs on the Arduino Nano board are used to brightness control the reflected light illuminator. One digital output is utilised to turn the warm white daylight reflected light illuminator on and off. There are additional N-Channel MOSFETs (International Rectifier IRF510 [70] for the THT version and Alpha&Omega Semiconductor AO3418 [47] for the final SMD version) and dropping resistors on both versions of the control board for the reflected light illuminators. The complete schematic and board layout as well as all data sheets for the final SMD version can be found in our public repository.

3.5.1 Arduino Firmware

The Arduino Nano or to be more precise the ATmega328P microcontroller on which it is based can be programmed in several different programming languages and development environments. We decided to use C++ together with the Arduino IDE to be able to utilise all the convenient Arduino libraries. There is a library for the TLC5940 included in the Arduino framework. Using this library the TLC5940 can be easily interfaced and controlled. It handles the serial protocol of the TLC5940 and setting/receiving of the brightness level values. It uses two out of the three internal timers of the ATmega328P, so if the TLC5940 library is utilised, only two of the six available PWM outputs on the Arduino Nano remain available for use (thus, we went on without being able to brightness control the warm white daylight reflected light in order to avoid adding another external hardware part). We implemented a simple protocol to interface each of the individual LEDs/laser modules as well as the reflected light illuminators, to set a whole stripe at once and to turn off all illuminators again. The Arduino Nano is recognised as USB serial port on the PC and a fixed-length text-based serial protocol, allowing for easy debugging, is used to send the command to the brightness control board. Details about the protocol as well as the brightness control board firmware can be found in our repository.

3.6 Finger Placement Unit

To provide an intuitive interaction with the scanner device and to help the capture subject at positioning their fingers correctly, the scanner has a finger guide or a finger placement unit. As the scanner captures the index, middle and ring fingers simultaneously, it is important that all three fingers are aligned with the underneath illumination stripes. This is especially important for the LED version of the scanner in order to avoid overexposed areas along the finger outline (refer to Sect. 3.3.3.2 for details on the advantages of the lasers over the LEDs). The finger placement unit, depicted in Fig. 3.14, is a custom-developed, 3D-printed part with three elliptically shaped grooves, each with a rectangular hole in the centre of the groove which is situated above the location where the LEDs or laser modules are placed. These grooves guide the capture subject at placing their fingers correctly and enable a natural and comfortable finger placement position during the capturing process, regardless if the fingers are placed in palmar or dorsal direction. Moreover, the finger placement unit was designed to prevent most kinds of finger misplacement, including tilts, planar finger rotation, horizontal shifts and especially longitudinal finger rotation by requiring the capture subject to place their finger flat on the placement unit with the fingers aligned to the grooves. In addition, the placement unit has two walls in between the index and middle and the middle and ring finger, respectively. These walls in combination with the shape of the grooves lead to a slightly spread position of the fingers, which makes an easy segmentation of the single fingers possible. Moreover, they block the diffuse light emitted sideways from the fingers which would otherwise lead to overexposed areas along the finger boundaries. In order to arrive at an optimal size and shape of the finger positioning support we performed several tests with male and female subjects, different age groups and different ethnicities (European, Asian, African). The current design is suitable for a broad range of people, especially for the average European and also for most adult Asian people. However, there might be some modifications necessary for younger Asian people with small hands/fingers. As it is a 3D-printed part, these adjustments to better suit different groups of people can be done easily. Note that adjustments have to be made to the LED/laser mounting brackets (see Sect. 3.3.3) too if the finger placement unit is changed.

3.7 Housing Parts

The housing for the PLUS OpenVein finger vein scanner was designed for two reasons. The first version of the scanner did not include an NIR pass-through filter, thus the housing was necessary to shield the scanner from the ambient light and improve the image contrast. Second, the wooden housing serves as a frame for mounting all the brackets and parts and putting the whole scanner assembly together. The housing consists of four wooden parts: two side panels, one front panel and one back panel which are connected using 3D-printed mounting brackets. The parts for the LED-based version are shown in Fig. 3.15. The laser module based version ones are not shown but only differ in their height (which are larger than the LED ones). There is an additional 3D-printed housing to accommodate the brightness control PCB which is mounted on the backplane (depicted in Fig. 3.5). The wooden parts are cut out of 4 mm plywood using a laser cutter. The current version of the scanner includes an NIR pass-through filter, so the wooden housing is mainly for stability and mounting reasons (except if the scanner is exposed to direct sunlight, then the housing is necessary to reduce the influence of the ambient light too). As studies showed that the capture subjects’ acceptance and convenience is higher for scanner devices built in a semi-open or fully open manner, we are planning to design a second version of the housing which has smaller side and front panels (semi-open design).

3.8 Capturing Software

So far, all the hardware parts of the scanner including the brightness controller firmware have been described. There is still one important thing missing, the scanner control software for capturing actual finger vein images. Our control software is based on the IDS Imaging uEye Software Suite [59] as the image sensor is an IDS camera. Their framework is available for Windows- and Linux-based operating systems. We implemented our capturing software for Windows using C# and Microsoft Visual Studio 2015. A screenshot of the capturing software can be seen in Fig. 3.16. Its functionality can be divided into four main parts:

-

1.

Initial scanner calibration: During initial scanner calibration the LED/laser module centres are set with the help of 3D-printed calibration sticks. This is essential for the automated brightness control algorithm to work correctly.

-

2.

Setting camera parameters: Here several camera parameters, e.g. frame rate, white balance, gain, pixel clock, exposure time, etc. can be set.

-

3.

Controlling the illumination sources: the light sources (light transmission and reflected light) can be either be controlled manually and individually or automatically. The manual control is only meant for troubleshooting purposes and tests while usually the automatic brightness control is applied.

-

4.

Image capturing: The image capturing process is designed to be semi-automated and convenient for a typical finger vein data collection. Some general settings, e.g. the directory to save the captured images, which kind of images (dorsal/palmar, left/right hand, light transmission/reflected light), how many images per kind and the desired average grey level can be set in advance. Then the session ID and the subject ID are set. Afterwards a single image can be captured or a fully automatic capturing run can be started. During the fully automatic capturing run, the desired number of images is captured and the software prompts to pull the hand out of the scanner and put it in again after each image. After all images per hand/side are captured, the software prompts to insert the next hand or change the side of the hand until all images for the current subject are captured. The illuminator brightness is adjusted automatically before each captured image according to the algorithm described in the following.

3.8.1 Automated Brightness Control Algorithm

In order to achieve an optimal image contrast especially in the vein regions, an automatic brightness control algorithm was developed. This algorithm controls each of the single light transmission illuminator LEDs/laser modules as well as the reflected light illuminators as a whole. After several tests with different image qualities and image contrast metrics, we opted for a simple, iterative algorithm based on a comparison against a target grey level. This algorithm works as follows: at first, the LED/laser centres have to be configured once as described below. This includes the determination of the area of influence for each LED/laser, which is the area in the image a single LED/laser illuminates (defined by a circle with a certain radius). Then all LEDs/lasers are set to an initial intensity level/brightness value which is half of their maximum intensity (\(I_{max}\)). The live image of the camera is analysed and the current grey level within the area of influence of each LED/laser is determined (\(GL_{current}\)) and compared against the set target grey level (\(GL_{target}\)). The new brightness value is then set according to \(I_{n+1}=I_{n}+I_{corr}\), where \(I_{n+1}\) is the new intensity level, \(I_{n}\) is the current intensity level and \(I_{corr}=\frac{GL_{target}-GL_{current}}{GL_{max}}\cdot \frac{I_{max}}{2\cdot n}\), where \(GL_{max}\) is the maximum grey value and n is the current iteration. The iteration stops if either the target grey level \(GL_{target}\) has been reached or if no more intensity change is possible. The algorithm finishes in at most \(log_{2}(I_{max}\)) iterations. Thus, it is fast enough for real-time applications while preserving a good performance in terms of uniform image contrast.

4 PLUSVein-FV3 Finger Vein Dataset

To demonstrate the high recognition performance that can be achieved by using our proposed scanner design, we established a dataset using both of our scanners, the LED-based version and the laser-based one. This dataset has already been published [12] and is available at: http://www.wavelab.at/sources/PLUSVein-FV3/. The first version contained dorsal finger vein images captured from 60 subjects, 6 fingers per subject and 5 images per finger in one session, summing up to a total of 3600 images from 360 individual fingers (1800 per scanner). Our scanners capture three fingers at once, so the 3600 images are actually extracted from 1200 raw finger vein images which were separated into three images corresponding to each individual finger. Those single finger images have a resolution of \(420\times 1024\) pixels and are stored in 8-bit greyscale png format. Some example images are shown in Fig. 3.17. In our previous work [12], we reported the recognition performance numbers that can be achieved using the dorsal images of our dataset, and thus our scanner design. We arrived at EERs as low as \(0.028\%\) and \(0.111\%\) for MC [20]/PC [2] and a SIFT-based approach [14], respectively, with these simple but well-established finger vein recognition schemes. In the meanwhile, we extended the dataset to contain palmar finger vein images captured from the same subjects too. Thus, it now includes a total of 7200 images, 1800 per scanner and per view (palmar/dorsal). In another recently published work [13], we compared the performance of palmar versus dorsal images. We showed that the best view in terms of recognition accuracy depends on the feature extraction algorithm, resulting in EER of \(0.08\%\) for the palmar images using MC and an EER of \(0.08\%\) for the dorsal images using SIFT. These performance figures approve the sophisticated and deliberate design of our finger vein scanners.

We are still extending our dataset in-house. The most recent version consists of about 100 subjects so far. The main reason for open sourcing our finger vein scanner design was to help other researchers working in the field of finger vein biometrics by sharing our custom-developed scanner design with them. The second most important reason is that we are interested in collaborations to extend our dataset and evolve it to an extensive, open finger vein dataset available for research purposes. If there are several reproductions of the scanner based on our design out there, every researcher having such a scanner device at hand and interested in participating could just provide the captured vein images and we will then include them in a new release of the open finger vein dataset.

We are currently discussing options for a suitable online platform to handle such a collaboration efficiently as well as trying to clarify the legal aspects (the consent forms have to include the right to merge the single datasets together which of course includes sharing the finger vein data with other partners in different countries and under different legislations) of sharing the finger vein images. We are confident that these two issues can be resolved soon.

5 Conclusion

This chapter proposes a new finger vein scanner design. After the introduction, the basic principle of a finger vein scanner is outlined, followed by a review on commercial finger vein scanners, available research finger vein datasets and the corresponding finger vein scanners used to establish these datasets. The main contribution of this chapter are the details about our fully open-source, modular, multipurpose finger vein scanner design. Our finger vein scanner design is based on commercial-off-the-shelf parts, a custom-developed brightness control board and custom-designed 3D-printed parts as well as laser-cut plywood parts. It is modular as each individual part can be replaced, modified and improved easily. This scanner is the first finger vein scanner that is able to capture reflected light as well as light transmission images. Moreover, it is able to capture three fingers at once (index, middle and ring finger) from the dorsal and palmar view (by rotating the hand around \(180^{\circ }\)). Thus, we call it a multipurpose finger vein scanner. Two different versions of the basic design are presented, one based on a conventional NIR LED illuminator, the second one based on NIR laser modules. Laser modules have not gotten much attention in finger vein recognition so far, despite their advantages especially if it comes to touchless operation. All the individual parts are described together with their design decisions. Our scanner design is fully open source: all technical details of the scanner design, including data sheets, parts lists, technical drawings and 3D models of the housing parts, firmware and software together with detailed assembly and setup instructions can be found in a public repository: http://www.wavelab.at/sources/PLUS-OpenVein. The use of our scanner design and the reproduction of the finger vein scanner according to our design is free of charge for research purposes. Thanks to our fully open-source design, other researchers can easily reproduce our scanner and utilise this scanner for their own finger vein data collection, meaning they are no longer dependent from publicly available datasets. Moreover, they can contribute their modifications and improvements to our scanner design as well. To confirm the decent recognition performance that can be achieved using our scanner design, we established a dataset using our two scanners. This dataset currently contains 7200 images from 360 individual fingers and is publicly available for research purposes at: http://www.wavelab.at/sources/PLUSVein-FV3.

5.1 Future Work

Although the current scanner design has been proven to be competitive in terms of recognition accuracy and usability, we still strive to improve it. The first improvement will be a rather small one. We will replace the NIR pass-through filter with an NIR bandpass filter for both versions of the scanner. This helps in further reducing the influence of the ambient light and is advantageous if it comes to the next improvement. The next change to the scanner design will include a removal of the side plates and the front plate to arrive at a more open or at least semi-open design. Scanners designed in an open manner have been shown to increase the capture subjects’ acceptability and convenience. Instead of removing the side plates completely we are thinking of making them only half of their current width such that the scanner becomes semi-open while still retaining its mechanical stability. The second improvement we are currently working on is the integration of the capturing software on a Raspberry Pi microcomputer as a first step towards a stand-alone, embedded finger vein scanner device which only requires an external power source but no additional PC for acquiring the images. The next step towards this stand-alone design is an additional touchscreen display, mounted at the front plate of the scanner device, connected to the Raspberry Pi and used to control the whole data acquisition process. Thanks to our fully open-source design, other researchers can contribute their modifications and improvements to our scanner design too.

Furthermore, we plan to establish a comprehensive, publicly available finger vein dataset for research purposes. Researchers who are interested in a contribution to this new finger vein dataset can simply build a scanner based on our open-source design, acquire finger vein images on their own and then contribute to the dataset by providing us their captured finger vein data. Such an extensive, available, collaborative finger vein dataset will be beneficial for the whole finger vein research community and is vital in order to achieve further progress in finger vein recognition. We are currently also extending the first version of our already available finger vein dataset in-house. Together with our partners and other researchers who are willing to contribute and build a scanner based on our design, we are confident that we will establish a comprehensive, open finger vein dataset from which the whole finger vein research community will benefit.

References

Asaari MSM, Suandi SA, Rosdi BA (2014) Fusion of band limited phase only correlation and width centroid contour distance for finger based biometrics. Expert Syst Appl 41(7):3367–3382

Choi JH, Song W, Kim T, Lee SR, Kim HC (2009) Finger vein extraction using gradient normalization and principal curvature. Proc SPIE 7251:9. https://doi.org/10.1117/12.810458

Commission IE et al (2006) IEC 62471: 2006. IEC Photobiological safety of lamps and lamp systems, Geneva

Commission IE et al (2007) Safety of laser products-part 1: equipment classification and requirements. IEC 60825–1

Daniel H (2012) Vascular pattern recognition and its application in privacy–preserving biometric online–banking system. PhD thesis, PhD dissertation, Gjovik University College

Eng PC, Khalil-Hani M (2009) Fpga-based embedded hand vein biometric authentication system. In: TENCON 2009 IEEE region 10 conference, pp 1–5

Fadhil RI, George LE (2017) Finger vein identification and authentication system. LAP Lambert Academic Publishing, Germany

Fletcher RR, Raghavan V, Zha R, Haverkamp M, Hibberd PL (2014) Development of mobile-based hand vein biometrics for global health patient identification. In: IEEE global humanitarian technology conference (GHTC 2014), pp 541–547

Hitachi Group, Corp (2018) Finger vein technology for Bank BPH (Poland)—Hitachi Europe News. http://www.hitachi.eu/en-gb/case-studies/finger-vein-technology-bank-bph-poland. Accessed 20 June 2018

Hitachi-Omron Terminal Solutions, Corp (2018) Taiwan’s CTBC bank adopts finger vein authentication solution for ATMs—Hitachi News. http://www.hitachi-omron-ts.com/news/pdf/201607-001.pdf. Accessed 20 June 2018

Huang B, Dai Y, Li R, Tang D, Li W (2010) Finger-vein authentication based on wide line detector and pattern normalization. In: 20th international conference on pattern recognition (ICPR) 2010. IEEE, pp 1269–1272

Kauba C, Prommegger B, Uhl A (2018) Focussing the beam—a new laser illumination based data set providing insights to finger-vein recognition. In: Proceedings of the IEEE 9th international conference on biometrics: theory, applications, and systems (BTAS2018), Los Angeles, California, USA, pp 1–9

Kauba C, Prommegger B, Uhl A (2018) The two sides of the finger—dorsal or palmar—which one is better in finger-vein recognition? In: Proceedings of the international conference of the biometrics special interest group (BIOSIG’18), Darmstadt, Germany

Kauba C, Reissig J, Uhl A (2014) Pre-processing cascades and fusion in finger vein recognition. In: Proceedings of the international conference of the biometrics special interest group (BIOSIG’14), Darmstadt, Germany

Kim J, Kong HJ, Park S, Noh S, Lee SR, Kim T, Kim HC (2009) Non-contact finger vein acquisition system using NIR laser. In: Sensors, cameras, and systems for industrial/scientific applications X, vol 7249. International Society for Optics and Photonics

Kumar A, Zhou Y (2012) Human identification using finger images. IEEE Trans Image Process 21(4):2228–2244

Lee EC, Jung H, Kim D (2011) New finger biometric method using near infrared imaging. Sensors 11(3):2319–2333

Liu Z, Song S (2012) An embedded real-time finger-vein recognition system for mobile devices. IEEE Trans Consum Electron 58(2):

Lu Y, Xie SJ, Yoon S, Wang Z, Park DS (2013) An available database for the research of finger vein recognition. In: 6th international congress on image and signal processing (CISP), 2013 , vol 1. IEEE, pp 410–415

Miura N, Nagasaka A, Miyatake T (2007) Extraction of finger-vein patterns using maximum curvature points in image profiles. IEICE Trans Inf Syst 90(8):1185–1194

Pascual JES, Uriarte-Antonio J, Sanchez-Reillo R, Lorenz MG (2010) Capturing hand or wrist vein images for biometric authentication using low-cost devices. In: Proceedings of the sixth international conference on intelligent information hiding and multimedia signal processing (IIH-MSP 2010), pp 816–819

Prommeger B, Kauba C, Uhl A (2019) A different view on the finger–multi-perspective score level fusion in finger-vein recognition. In: Uhl A, Busch C, Marcel S, Veldhuis R (eds) Handbook of vascular biometrics. Springer Science+Business Media, Boston, MA, USA, pp 395–434

Prommegger B, Kauba C, Uhl A (2018) Longitudinal finger rotation—problems and effects in finger-vein recognition. In: Proceedings of the international conference of the biometrics special interest group (BIOSIG’18), Darmstadt, Germany

Raghavendra R, Busch C (2015) Exploring dorsal finger vein pattern for robust person recognition. In: 2015 international conference on biometrics (ICB), pp 341–348. https://doi.org/10.1109/ICB.2015.7139059

Raghavendra R, Raja KB, Surbiryala J, Busch C (2014) A low-cost multimodal biometric sensor to capture finger vein and fingerprint. In: IEEE international joint conference on biometrics (IJCB), 2014. IEEE, pp 1–7

Raghavendra R, Venkatesh S, Raja K, Busch C (2018) A low-cost multi-finger vein verification system. In: proceedings of international conference on imaging systems and techniques (IST 2018), Karkow, Poland

Shaheed K, Liu H, Yang G, Qureshi I, Gou J, Yin Y (2018) A systematic review of finger vein recognition techniques. Information 9:213

Ting E, Ibrahim M (2018) A review of finger vein recognition system. J Telecommun Electron Comput Eng 10(1–9):167–171

Today BT (2014) Uk banking customers ready for finger biometrics authentication. Biom Technol Today 2014(9):3–12. 10.1016/S0969-4765(14)70138-9 http://www.sciencedirect.com/science/article/pii/S0969476514701389

Tome P, Vanoni M, Marcel S (2014) On the vulnerability of finger vein recognition to spoofing. In: IEEE international conference of the biometrics special interest group (BIOSIG). URL http://publications.idiap.ch/index.php/publications/show/2910

Ton B (2012) Vascular pattern of the finger: biometric of the future? sensor design, data collection and performance verification. Master’s thesis, University of Twente

Ton B, Veldhuis R (2013) A high quality finger vascular pattern dataset collected using a custom designed capturing device. In: International conference on biometrics, ICB 2013. IEEE. URL http://doc.utwente.nl/87790/

University of Reading (2017) PROTECT multimodal DB dataset. http://projectprotect.eu/dataset/

University of Salzburg (2018) PLUSVein-FV3 finger-vein data set. http://www.wavelab.at/sources/PLUSVein-FV3