Abstract

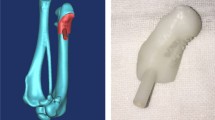

The purpose of this study was to show a 3D printed reconstruction model of a bone destroyed by a comminuted fracture. After a thoracic limb of a cow with a comminuted fracture was scanned by using computed tomography, a scaffold was designed by using a 3D modeling tool for its reconstruction and fabricated by using a homemade medical 3D printer. The homemade medical 3D printer was designed for medical use. In order to reconstruct the geometry of the destroyed bone, we use the geometry of a similar section (reference geometry) of normal bone in the 3D modeling process. The missing part between the destroyed ridge and the reference geometry was filled with an effective space by using a manual interpolation. Inexpensive materials and free software were used to construct the medical 3D printer system. The fabrication of the scaffold progressed according to the design of reconstructed bone by using this medical 3D printer. The material of the scaffold was biodegradable material, and could be transplanted into the human body. The fabricated scaffold was correctly inserted into the fractured bone in place of the destroyed portion, with good agreement. According to physical stress test results, the performance of printing resolution was 0.1 mm. The average geometrical error of the scaffold was below 0.3 mm. The reconstructed bone by using the fabricated scaffold was able to support the weight of the human body. No process used to obtain the result was complex or required many resources. The methods and results in this study show several possible clinical applications in fields such as orthopedics or oncology without a need to purchase high-price instruments for 3D printing.

Similar content being viewed by others

References

A. Businger, P. R. Thomas and C. Sommer, Injury 41, 583 (2010).

S. Siebenlist et al., Injury 41, 1306 (2010).

T. Shimizu et al., Injury 43, 940 (2012).

J. A. Disegi and L. Eschbach, Injury 31, D2 (2000).

S. V. Murphy, A. Atala, Nat. Biotechnol. 32, 773 (2014).

S. Choi, H. Kang and H. Bang, Injury 45, 1280 (2014).

E. F. Morgan et al., Bone 44, 335 (2009).

K. R. O’Neill et al., Bone 50, 1357 (2012).

B. Liu et al., Comput. Med. Imaging Graph. 38, 233 (2014).

C. X. F. Lam et al., Mater. Sci. Eng. C Mater. Biol. Appl. 20, 49 (2002).

M. Lee, J. C. Dunn and B. M. Wu, Biomaterials 26, 4281 (2005).

E. Jeandupeux, V. Lobjois and B. Ducommun, Biochem. Biophys. Res. Commun. 463, 1141 (2015).

H. J. Lee et al., Injury 44, 465 (2013).

P. Lichte et al., Injury 42, 569 (2011).

L. M. Mathieu et al., Biomaterials 27, 905 (2006).

R. Olszewski, P. Szymor and M. Kozakiewicz, J. Craniomaxillofac. Surg. 42, 1847 (2014).

A. L. Jardini et al., J. Craniomaxillofac. Surg. 42, 1877 (2014).

A. Butscher et al., Acta. Biomater. 7, 907 (2011).

Q. Zhang et al., Sci. Rep. 5, 8936 (2015).

L. Ciocca et al., Clin. Oral. Implants Res. 22, 850 (2011).

S. J. Hollister, Nat. mater. 4, 518 (2005).

Y. He, G. H. Xue and J. Z. Fu, Sci. Rep. 4, 6973 (2014).

D. Palousek, J. Rosicky and D. Koutny, Prosthet. Orthot. Int. 38, 171 (2013).

L. Horváth et al., Sci. Rep. 5, 7974 (2015).

A. I. Birkhold et al., Bone 66, 15 (2014).

K. Iwata et al., Bone 64, 183 (2014).

S. Rehman, T.A. Damron and C. Geel, Injury 31, 783 (2000).

K. H. Yang, Injury 36, 75 (2005).

R. N. Thompson, C. L. Armstrong and G. Heyburn, Bone 61, 44 (2014).

J. Ho-Seung et al., Arch. Orthop. Trauma. Surg. 134, 1551 (2014).

H. Huajun et al., Australas. Phys. Eng. Sci. Med. 38, 109 (2015).

E. Maravelakis et al., J. Med. Eng. Technol. 32, 115 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoon, DK., Jung, JY., Shin, HB. et al. Fabrication of a customized bone scaffold using a homemade medical 3D printer for comminuted fractures. Journal of the Korean Physical Society 69, 852–857 (2016). https://doi.org/10.3938/jkps.69.852

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.69.852