Abstract

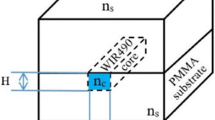

This study proposes a simple cost-effective method of optical interconnection with a view to minimizing and overcoming the excess loss caused by the alignment tolerance between optical waveguides in the integration/interface process in order to fabricate a large-area optical circuit layer. To that end, a large-area polymeric mold with a continuous channel structure was fabricated. The fabrication process consisted of fabricating the primary polymer mold by using the original master in the polymer replication process and involved the simple alignment of the replicated polymeric mold so that only some sections overlapped with the original master. The dimensions (i.e., width and thickness) of the cavity of the polymeric mold were identical to those of the original master. When the original master was inserted into the cavity of the polymeric mold after having separated the original master and the polymeric mold, the rib structures of the original master and the channel structures of the polymeric mold could be arranged in a passive alignment. A large-area polymeric mold with a continuous channel structure was fabricated by coating a polymeric solution onto the non-overlapping original master. For this study, a polymeric multimode optical waveguide with a length of 200 mm was fabricated using the original master with a length of 130 mm with 50 straight ribs. The excess loss of the proposed large-area multimode optical waveguide interconnection, compared with the original master-based optical waveguide, was 0 dB at 850 nm.

Similar content being viewed by others

References

B. S. Rho, S. H. Hwang, J. W. Lim, G. W. Kim, C. H. Cho and W. J. Lee, Opt. Express 17, 1215 (2009).

J. H. Ryu, T. H. Lee, I. K. Cho, C. S. Kim and M. Y. Jeong, Opt. Express 19, 1183 (2011).

W. Ni, X. Wu and J. Wu, Opt. Express 17, 1194 (2009).

F. Wang, F. Liu and A. Adibi, Opt. Express 17, 10514 (2009).

S. Uhlig, L. Frohlich, M. Chen, N. A. Staufenbiel, G. Lang, H. Schroder, R. Houbertz, M. Popall and M. Robertsson, IEEE Trans. Adv. Packag. 29, 158 (2006).

H. Kim, Y. M. Im, K. W. Lee, S. H. Cho, J. G. Park and B. S. Yoo, J. Korean Phys. Soc. 57, 1589 (2010).

J. H. Kim, J. S. Choe, C. J. Youn, D. J. Kim, Y. H. Kwon and E. S. Nam, ETRI J. 34, 946 (2012).

S. Kim, S. H. Ahn and S. S. Park, ETRI J. 35, 578 (2013).

J. H. Ryu, T. H. Lee, S. H. Oh, S. U. Cho, C. S. Kim and M. Y. Jeong, Curr. Appl. Phys. 9, e7 (2009).

J. H. Ryu, P. J. Kim, C. S. Cho, E. H. Lee, C. S. Kim and M. Y. Jeong, Opt. Express 19, 8571 (2011).

W. J. Lee, S. H. Hwang, J. W. Lim and B. S. Rho, IEEE Photon. Technol. Lett. 21, 12 (2009).

T. Ishigure and Y. Nitta, Opt. Express 18, 14191 (2010).

X. Dou, X. Wang, H. Huang, X. Lin, D. Ding, D. Z. Pan and R. T. Chen, Opt. Express 18, 378 (2010).

S. H. Hwang, W. J. Lee, M. J. Kim, E. J. Jung and B. S. Rho, Opt. Quant. Electron. 44, 189 (2012).

S. Y. Chou, P. R. Krauss and P. J. Renstrom, J. Vac. Sci. Technol. B 14, 4129 (1996).

S. H. Oh, S. U. Cho, C. S. Kim, Y. G. Han, C. S. Cho and M. Y. Jeong, Microelectron. Eng. 88, 2900 (2011).

J. T. Kim, B. C. Kim, M. Y. Jeong and M. S. Lee, J. Mater. Process. Technol. 146, 163 (2004).

H. Mizuno, O. Sugihara, S. Jordan, N. Okamoto, M. Ohama and T. Kaino, J. Lightwave Technol. 24, 919 (2006).

A. H. Cannon and W. P. King, J. Micromech. Microeng. 19, 095016 (2009).

Y. T. Cho, S. Kwon, J. W. Seo, J. G. Kim, J. W. Cho, J. W. Park, H. Kim and S. W. Lee, Microelectron. Eng. 86, 2417 (2009).

A. Neyer, B. Wittmann and M. Johnck, IEEE J. Sel. Top. Quantum Electron. 5, 193 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ryu, J.H., Lee, B.K., Baek, KH. et al. Fabrication of low-loss optical interconnected waveguide using a replicated seamless large-area polymeric mold. Journal of the Korean Physical Society 65, 450–456 (2014). https://doi.org/10.3938/jkps.65.450

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.65.450