Abstract

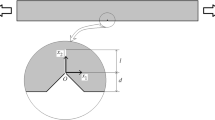

Strengthening and toughening mechanisms in composite ceramics is complex. A change in a single parameter induces multiple property variations. The multiple changes in properties are often incompletely represented in theoretical models. This incompleteness in the parameter chosen fails to explain the mechanism of failure in composite ceramics. The exponential toughness function is used to represent the pull-out toughening mechanism, which dominates the crack growth resistance curve(R-curve). The strengthening-toughening model is established based on the Mori-Tanaka method(M-T method). The influence of inherent defects on toughness function and strength is analyzed by using this model. The theoretical result is compared with the experiment data. This model exactly reflects the change in strength. The theoretical result indicates that defects change the toughness function. Moreover, micro-cracks increase toughness size a c, and the strength of crack instable extensions acutely decreases as defect content increases. This presented model establishes the relationship among the important mechanical parameters of defect, strength, elastic modulus, and the R-curve.

Similar content being viewed by others

References

MARSHALL D B, COX B N, EVANS A G. The mechanics of matrix cracking in brittle-matrix fiber composites[J]. Acta Metall, 1985, 33(11): 2013–2021.

JAE-SEOL L, TOYOHIKO Y. Fabrication of short-fiber-reinforced SiC composites by polycarbosilane infiltration[J]. Journal of the European Ceramic Society, 2004, 24(1): 25–31.

KRSTIC V V, NICHOISON P S, HOAGLAND R G. Toughening of glasses by metallic particles[J]. J. Am. Ceram. Soc., 1981, 64(9): 499–504.

YEOMANS J A. Ductile particle ceramic matrix composites-scientific curiosities or engineering materials?[J]. Journal of the European Ceramic Society, 2008, 28(7): 1543–1550.

LIU Y G, ZHOU J Q, SHEN T D. Effect of nano-metal particles on the fracture toughness of metal-ceramic composite[J]. Materials and Design, 2013, 45: 67–71.

EVANS A G. Perspective on the development of high-toughness ceramics[J]. J. Am. Ceram. Soc., 1990, 73: 187–195.

KELLY P M, FRANCIS ROSE L R. The martensitic transformation in ceramics-its role in transformation toughening [J]. Prog Mater Sci, 2002, 47(5): 463–557.

QIAO Y, KONG X G. Unstable crack advance across a regular array of short fibers in brittle matrix[J]. Composites Science and Technology, 2004, 64(5): 711–717.

NI X H. Research on micromechanical model and macro mechanical properties for composite ceramics with interphase[D]. Shijiazhuang: Ordnance Engineering College, 2008. (in Chinese)

LI W F, DU S Y. Stress and strength of elastic matrix with misoriented microcracks and prolate spheroids[J]. Acta Mechanica Sinica, 1994, 26(5): 541–550. (in Chinese)

PALIWAL B, RAMESH K T. An interacting micro-crack damage model for failure of brittle materials under compression[J]. Journal of the Mechanics and Physics of Solids, 2008, 56(3): 896–923.

SONG S X, QIU X N. Discussion on the expressions of R-curve behavior of ceramic materials[J]. Journal of University of Jinan, 2007, 21(3): 197–199. (in Chinese)

COOK R F, CLARKE D R. Fracture stability R-curves strength variability[J]. Act Metal, 1988, 36(3): 555–562.

CHEN J P, XI J, GUAN Z D. Study on the regressive parameters of R-curve behavior for ceramic composite[J]. Journal of the Chinese Ceramic Society, 1997, 25(1): 37–43. (in Chinese)

RAMACHANDRAN N, SHETTY D K. Rising crack-growth-resistance(R-curve) behavior of toughened alumna and silicon nitride[J]. J Am Ceram Soc, 1991, 74(10): 2634–2641.

DONG Q W, FENG P, SUN Y, et al. Influence of bridging characteristics on fracture resistance curves[J]. Journal of Harbin Institute of Technology, 2002, 34(3): 348–351. (in Chinese)

RADDATZ O, SCHNEIDER G A, CLAUSSEN N. Modelling of R-curve behavior in ceramic/metal composites[J]. Acta Mater., 1998, 46(18): 6381–6395.

FÜNFSCHILLING S, FETT T, HOFFMANN M J, et al. Mechanisms of toughening in silicon nitrides: The roles of crack bridging and microstructure[J]. Acta Materialia, 2011, 59(10): 3978–3989.

ZOU L H, HUANG Y, PARK D S, et al. R-curve behavior of Si3N4 whisker-reinforced Si3N4 matrix composites[J]. Ceramics International, 2004, 31(1): 197–204.

RADDATZ O, SCHNEIDER G A, CLAUSSEN N. Modeling of R-curve behavior in ceramic/metal composites[J]. Acta Mater., 1998, 46(18): 6381–6395.

RADDATZ O, SCHNEIDER G A, MACKENS W, et al. Bridging stresses and R-curves in ceramic/metal composites[J]. Journal of the European Ceramic Society, 2000, 20(13): 2261–2273.

ZHAO Z M, ZHANG L, SONG Y L, et al. Composition microstructures and properties of Al2O3/ZrO2(4Y) prepared by combustion synthesis under high gravity[J]. Special Casting & Nonferrous Alloys, 2008, (S1): 297–302. (in Chinese)

PAN C Z, ZHANG L, ZHAO Z M, et al. Growth mechanisms of Al2O3/ZrO2(Y2O3) eutectic composite ceramic[J]. Materials Science and Engineering of Powder Metallurgy, 2007, 12(5): 290–295. (in Chinese)

YU G B, YAN W, WANG S H, et al. Toughening mechanism of lined Al2O3-ZrO2 multiphase ceramics in SHS composite pipes[J]. Journal of University of Science and Technology Beijing, 2006, 13(2): 178–182.

ZHENG Q S, DU D X. An explicit and universally applicable estimate for the effective properties of multiphase composites which accounts for inclusion distribution[J]. J. Mech. Phys. Solids, 2001, 49(11): 2765–2788.

YU S W, FENG X Q. Damage mechanics[M]. Beijing: Tsinghua University Press, 1997. (in Chinese)

WANG D G, ZHONG L L, GU L X. Preparation and application of alumina fibers[J]. New Chemical Materials, 2002, 30(4): 17–19. (in Chinese)

MORI T, TANAKA K. Average stress in matrix and average energy of materials with misfitting inclusion[J]. Act. Metal, 1973, 21: 571–574.

FU Y W, LIU X Q, NI X H, et al. Effective elastic property prediction of ceramic composite with inherent defect[J]. Journal of Mechanical Engineering, 2012, 48(16): 46–51. (in Chinese)

ZHAO Z M, ZHANG L, BAI H B, et al. Microstructure and different-scale multistage toughening of self-toughening composite ceramics with in-situ growing nano-micron fibers[J]. Rare Metal Materials and Engineering, 2006, 35 (S2): 91–95. (in Chinese)

ZHAO Z M, ZHANG L, SONG Y L, et al. Influences of ZrO2 on Al2O3/ZrO2(4Y) prepared by combustion synthesis under high gravity[J]. Rare Metal Materials and Engineering, 2009, 38 (S2): 98–101. (in Chinese)

ZHAO Z M, ZHANG L, ZHANG S Y, et al. Microstructures and mechanical properties of large-scale Al2O3/ZrO2(Y2O3) self-growing ceramic plates prepared by combustion synthesis under high gravity[C]//International Conference on Smart Materials and Nanotechnology in Engineering, Harbin, China, July 1–4, 2007: 64235B1–64235B8.

ZHAO Z M, ZHANG L, SONG Y G, et al. Al2O3/ZrO2(Y2O3) self-growing composites prepared by combustion synthesis under high gravity[J]. Scripta Materialia, 2008, 58(3): 207–210.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China(Grant No. 11272355)

FU Yunwei, born in 1986, is currently a PhD candidate at Department of Vehicle and Electric Engineering, Ordnance Engineering College, China. His research interest is composite damage and fracture mechanism.

ZHANG Long, born in 1957, is currently a professor at Department of Vehicle and Electric Engineering, Ordnance Engineering College, China. His research interest is advanced composite ceramic.

NI Xinhua, born in 1963, is currently a professor at Department of Vehicle and Electric Engineering, Ordnance Engineering College, China. Her research interest is composite damage and fracture mechanism.

LIU Xiequan, born in 1962, is currently a professor at Department of Vehicle and Electric Engineering, Ordnance Engineering College, China. His research interest is strength analysis.

CHEN Cheng, born in 1989, is currently a master candidate at Department of Vehicle and Electric Engineering, Ordnance Engineering College, China. His research interest is damage mechanics of composite.

ZHAO Siyuan, born in 1987, is currently a teaching assistant at Department of Ground Artillery, Wuhan Ordnance Non-commissioned Officers Academy, China. His research interest is advanced composite ceramic.

Rights and permissions

About this article

Cite this article

Fu, Y., Zhang, L., Ni, X. et al. Strength-toughening model of eutectic ceramic composite with inherent defects. Chin. J. Mech. Eng. 27, 754–760 (2014). https://doi.org/10.3901/CJME.2014.0418.077

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2014.0418.077