Abstract

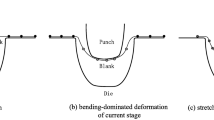

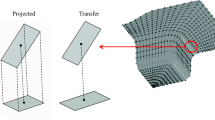

In one step inverse finite element approach, an initial blank shape is normally predicted from the final deformed shape. The final deformed shape needs to be trimmed into a final part after stamping, the trimmed area, therefore, needs to be compensated manually before using one step inverse approach, which causes low efficiency and in consistency with the real situation. To solve this problem, one step positive approach is proposed to simulate the sheet metal stamping process. Firstly the spatial initial solution of one step positive method is preliminarily obtained by using the mapping relationship and area coordinates, then based on the deformation theory the iterative solving is carried out in three-dimensional coordinate system by using quasi-conjugate-gradient method. During iterative process the contact judgment method is introduced to ensure that the nodes on the spatial initial solution are not separated from die surface. The predicted results of sheet metal forming process that include the shape and thickness of the stamped part can be obtained after the iterative solving process. The validity of the proposed approach is verified by comparing the predicted results obtained through the proposed approach with those obtained through the module of one step inverse approach in Autoform and the real stamped part. In one step positive method, the stamped shape of regular sheet can be calculated fast and effectively. During the iterative solution, the quasi-conjugate-gradient method is proposed to take the place of solving system of equations, and it can improve the stability and precision of the algorithm.

Similar content being viewed by others

References

BATOZ J L, GUO Y Q, MERCIER F. The inverse approach with simple triangular shell elements for large strain predictions of sheet metal forming parts[J]. Engineering Computations, 1998, 15(7): 864–892.

GUO Y Q, NACEUR H, DEBRAY K, et al. Initial solution estimation to speed up inverse approach in stamping modeling[J]. Engineering Computations, 2003, 20(7–8): 810–834.

NACEUR H, DELAMEZIERE A, BATOZ J L, et al. Some improvements on the optimum process design in deep drawing using the inverse approach[J]. Journal of Materials Processing Technology, 2004, 146(2): 250–262.

NACEUR H, GUO Y Q, BATOZ J L. Blank optimization in sheet metal forming using an evolutionary algorithm[J]. Journal of Materials Processing Technology, 2004, 151(1–3): 183–191.

LI Y M, ABBES B, GUO Y Q. Two efficient algorithms of plastic integration for sheet forming modeling[J]. Journal of Manufacturing Science and Engineering-Transactions of the ASME, 2007, 129(4): 698–704.

NACEUR H, BEN-ELECHI S, BATOZ J L, et al. Response surface methodology for the rapid design of aluminum sheet metal forming parameters[J]. Materials and Design, 2008, 29(4): 781–790.

CHUNG K, BARLAT F, BREM J C, et al. Blank shape design for a planar anisotropic sheet based on ideal forming design theory and FEM analysis[J]. International Journal of Mechanical Sciences, 1997, 39(1): 105–120.

YOON J W, CHUNG K, POURBOGHRAT F, et al. Design optimization of extruded perform for hydroforming processes based on ideal forming design theory[J]. International Journal of Mechanical Sciences, 2006, 48(12): 1 416–1 428.

LEE M G, CHUNG K, WAGONER R H, et al. A numerical method for rapid estimation of drawbead restraining force based on non-linear, anisotropic constitutive equations[J]. International Journal of Solids and Structures, 2008, 45(11–12): 3 375–3 391.

LAN Jian, DONG Xianghuai, LI Zhigang. Inverse finite element approach and its application in sheet metal forming[J]. Journal of Materials Processing Technology, 2005, 17(3): 624–631.

KIM Seung Ho, KIM Se Ho, HUH Hoon. Finite element inverse analysis for the design intermediate dies in multi-stage deep drawing processes with large aspect ratio[J]. Journal of Materials Processing Technology, 2001, 113(1–3): 779–785.

BAO Yidong, HUH H. Optimum design of trimming line by one-step analysis for auto body parts[J]. Journal of Materials Processing Technology, 2007, 187: 108–112.

TANG Bingtao, ZHAO Zhen, CHEN Jun, et al. Development of multistage sheet metal forming simulation based on multi-step inverse analysis approach[J]. Chinese Journal of Mechanical Engineering, 2006, 42(12): 211–217. (in Chinese)

TANG Bingtao, ZHAO Zhen, LU Xiaoyang, Developments of multistep inverse finite element method and its application in formability prediction of multistage sheet metal forming[J]. Journal of Manufacturing Science and Engineering, 2010, 132(4): 041013–041019.

REZA Azizi. Different implementations of inverse finite element method in sheet metal forming[J]. Materials and Design, 2009, 30(8): 2 975–2 980.

REZA Azizi, AHMAD Assempour. Applications of linear inverse finite element method in prediction of the optimum blank in sheet metal forming[J]. Materials and Design, 2008, 29(10): 1 965–1 972.

FAZLI A, AREZOO B. A comparison of numerical iteration based algorithms in blank optimization[J]. Materials and Design, 2012, 50(1): 207–216.

Author information

Authors and Affiliations

Corresponding author

Additional information

This project is supported by National Natural Science Foundation of China (Grant No. 51075187)

NA Jingxin, born in 1957, is currently a professor and a PhD supervisor at Jilin University, China. His main research interests include fast simulation for metal sheet forming process, lightweight design for body structure.

CHEN Wei, born in 1985, is currently a PhD candidate at Jilin University, China. His research interests include fast simulation for metal sheet forming process.

Rights and permissions

About this article

Cite this article

Na, J., Chen, W. One step positive approach for sheet metal forming simulation based on quasi-conjugate-gradient method. Chin. J. Mech. Eng. 26, 730–736 (2013). https://doi.org/10.3901/CJME.2013.04.730

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2013.04.730