Abstract

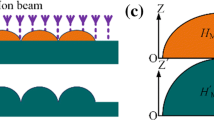

Aspherical microlenses and microlens arrays allow increasing efficiency of various optical devices. However, it is technologically challenging to produce these items. The problem arises from impossibility of making microlenses with an arbitrary profile in a characteristic size region of several tens of micrometers using traditional technologies like single-point diamond milling and thermal reflow. In this work, a precisely aligned combination of an aspherical microlens and a microlens array produced by the two-photon polymerization direct laser writing (2PP-DLW) is presented. This structure is designed and optimized using computer simulation methods. A unique photosensitive composition based on the methacrylate dye (derivative of benzylidene cyclopentanone) is used to produce the structures. A specific feature of the chosen composition is dependence of its mechanical and optical properties on the femtosecond radiation dose which could widely vary during the fabrication. The produced structures are investigated using laser scanning confocal microscopy, which allows reconstruction of the 3D image of the structures and detailed analysis of their morphological properties. The aspherical microlens aligned with the microlens array has a wide range of applications in production of complicated optical devices, optimized microobjective lenses for high-precision wave front sensing, and refractive X-ray lenses.

Similar content being viewed by others

REFERENCES

P. Gatkine, S. Veilleux, and M. Dagenais, “Astrophotonic spectrographs,” Appl. Sci. 9 (2), 290 (2019). https://doi.org/10.3390/app9020290

A. Camposeo, L. Persano, M. Farsari, and D. Pisignano, “Additive manufacturing: applications and directions in photonics and optoelectronics,” Adv. Opt. Mater. 7 (1), 1800419 (2019). https://doi.org/10.1002/adom.201800419

N. Giannekas, P. M. Kristiansen, Y. Zhang, and G. Tosello, “Investigation of product and process fingerprints for fast quality assurance in injection molding of micro-structured components,” Micromachines 9 (12), 661 (2018). https://doi.org/10.3390/mi9120661

Z. Shi, X. Shi, M. W. Ullah, S. Li, V. V. Revin, and G. Yang, “Fabrication of nanocomposites and hybrid materials using microbial biotemplates,” Adv. Compos. Hybrid Mater. 1 (1), 79–93 (2018). https://doi.org/10.1007/s42114-017-0018-x

A. Sheng, L. Lin, J. Zhu, J. Zhuang, J. Li, L. Chang, and H. Cheng, “Micro/nanodevices for assessment and treatment in stomatology and ophthalmology,” Microsyst. Nanoeng. 7 (1), 11 (2021). https://doi.org/10.1038/s41378-021-00238-1

K. Li, G. Xu, X. Huang, Z. Xie, and F. Gong, “Manufacturing of micro-lens array using contactless micro-embossing with an EDM-mold,” Appl. Sci. 9 (1), 85 (2018). https://doi.org/10.3390/app9010085

H. Zhang, T. Qi, X. Zhu, L. Zhou, Z. Li, Y. F. Zhang, W. Yang, J. Yang, Z. Peng, G. Zhang, F. Wang, P. Guo, and H. Lan, “3D printing of a PDMS cylindrical microlens array with 100% fill-factor,” ACS Appl. Mater. Interfaces 13 (30), 36295–36306 (2021). https://doi.org/10.1021/acsami.1c08652

Y. Motoyama, K. Sugiyama, H. Tanaka, H. Tsuchioka, K. Matsusaki, and H. Fukumoto, “High-efficiency OLED microdisplay with microlens array,” J. Soc. Inf. Disp. 27 (6), 354–360 (2019). https://doi.org/10.1002/jsid.784

C. Fang, J. Zheng, Y. Zhang, Y. Li, S. Liu, W. Wang, T. Jiang, X. Zhao, and Z. Li, “Antireflective paraboloidal microlens film for boosting power conversion efficiency of solar cells,” ACS Appl. Mater. Interfaces 10 (26), 21950–21956 (2018). https://doi.org/10.1021/acsami.7b19743

P.-I. Dietrich, R. J. Harris, M. Blaicher, M. K. Corrigan, T. J. Morris, W. Freude, A. Quirrenbach, and C. Koos, “Printed freeform lens arrays on multi-core fibers for highly efficient coupling in astrophotonic systems,” Opt. Express 25 (15), 18288–18295 (2017). https://doi.org/10.1364/oe.25.018288

P. I. Dietrich, M. Blaicher, I. Reuter, M. Billah, T. Hoose, A. Hofmann, C. Caer, R. Dangel, B. Offrein, U. Troppenz, M. Moehrle, W. Freude, and C. Koos, “In situ 3D nanoprinting of free-form coupling elements for hybrid photonic integration,” Nat. Photonics 12 (4), 241–247 (2018). https://doi.org/10.1038/s41566-018-0133-4

P. Hottinger, R. J. Harris, P.-I. Dietrich, M. Blaicher, M. Glück, A. Bechter, J.-U. Pott, O. Sawodny, A. Quirrenbach, J. Crass, and C. Koos, “Micro-lens arrays as tip-tilt sensor for single mode fiber coupling,” Proc. SPIE 10706, 1070629 (2018). https://doi.org/10.1117/12.2312015

H. M. Kim, M. S. Kim, G. J. Lee, Y. J. Yoo, and Y. M. Song, “Large area fabrication of engineered microlens array with low sag height for light-field imaging,” Opt. Express 27 (4), 4435–4444 (2019). https://doi.org/10.1364/oe.27.004435

Z.-B. Fan, H.-Y. Qiu, H.-L. Zhang, X.-N. Pang, L.-D. Zhou, L. Liu, H. Ren, Q.-H. Wang, and J.‑W. Dong, “A broadband achromatic metalens array for integral imaging in the visible,” Light: Sci. Appl. 8 (1), 67 (2019). https://doi.org/10.1038/s41377-019-0178-2

S. P. Yang, J.-B. Kim, and K.-H. Jeong, “Pattern projector using superposition of double microlens arrays for hybrid 3D endoscope,” Proc. IEEE Int. Conf. on Micro Electro Mechanical Systems, Belfast, UK, January 21–25, 2018 (IEEE, 2018), pp. 422–425. https://doi.org/10.1109/MEMSYS.2018.8346578

V. Grigaliūnas, A. Lazauskas, D. Jucius, D. Viržonis, B. Abakevičienė, S. Smetona, and S. Tamulevičius, “Microlens fabrication by 3D electron beam lithography combined with thermal reflow technique,” Microelectron. Eng. 164, 23–29 (2016). https://doi.org/10.1016/j.mee.2016.07.003

S. Cai, Y. Sun, H. Chu, W. Yang, H. Yu, and L. Liu, “Microlenses arrays: Fabrication, materials, and applications,” Microsc. Res. Tech. 84 (11), 2784–2806 (2021). https://doi.org/10.1002/jemt.23818

S. Kawata; H.-B. Sun, T. Tanaka, and K. Takada, “Finer features for functional microdevices,” Nature 412, 697–698 (2001). https://doi.org/10.1038/35089130

J. R. Freitas, S. Pimenta, J. F. Ribeiro, T. Dong, Z. Yang, and J. H. Correia, “Simulation, fabrication and morphological characterization of a PDMS microlens for light collimation on optrodes,” Optik 227, 166098 (2021). https://doi.org/10.1016/j.ijleo.2020.166098

F. Loffredo, F. Villani, C. Cancro, G. Nenna, A. Borriello, R. Miscioscia, C. Minarini, and F. Roca, “Evaluation of the PMMA microlens efficiency for the realization of a solar micro-concentrator array,” Appl. Opt. 57 (16), 4396–4401 (2018). https://doi.org/10.1364/AO.57.004396

M. Mikuła, T. Kozacki, M. Józwik, and J. Kostencka, “Accurate shape measurement of focusing microstructures in Fourier digital holographic microscopy,” Appl. Opt. 57 (1), A197–A204 (2018). https://doi.org/10.1364/AO.57.00A197

B. Murić, D. Pantelić, D. Vasiljević, and B. Panić, “Microlens fabrication on tot’hema sensitized gelatin,” Opt. Mater. 30 (7), 1217–1220 (2008). https://doi.org/10.1016/j.optmat.2007.05.051

B. D. Murić, D. V. Pantelić, D. M. Vasiljević, and B. M. Panić “Properties of microlenses produced on a layer of tot’hema and eosin sensitized gelatin,” Appl. Opt. 46 (35), 8527–8532 (2007). https://doi.org/10.1364/AO.46.008527

A. V. Pisarenko, R. D. Zvagelsky, D. A. Kolymagin, B. V. Katanchiev, A. G. Vitukhnovsky, and D. A. Chubich, “DLW-printed optical fiber micro-connector kit for effective light coupling in optical prototyping,” Optik 201, 163350 (2020). https://doi.org/10.1016/j.ijleo.2019.163350

E. R. Zhiganshina, M. V. Arsenyev, D. A. Chubich, D. A. Kolymagin, A. V. Pisarenko, D. S. Burkatovsky, E. V. Baranov, A. G. Vitukhnovsky, A. N. Lobanov, R. P. Matital, D. A. Aleynik, and S. A. Chesnokov, “Tetramethacrylic benzylidene cyclopentanone dye for one- and two-photon photopolymerization Eur. Polym. J. 162, 110917 (2022). https://doi.org/10.1016/j.eurpolymj.2021.110917

A. E. Egorov, A. A. Kostyukov, D. A. Shcherbakov, D. A. Kolymagin, D. A. Chubich, R. P. Matital, M. V. Arsenyev, I. D. Burtsev, M. G. Mestergazi, E. R. Zhiganshina, S. A. Chesnokov, A. G. Vitukhnovsky, and V. A. Kuzmin, “Benzylidene cyclopentanone derivative photoinitiator for two-photon photopolymerization-photochemistry and 3D structures fabrication for X-ray application,” Polymers 15 (1), 71 (2023). https://doi.org/10.3390/polym15010071

R. P. Matital, D. A. Kolymagin, D. A. Chubich, D. D. Merkushev, and A. G. Vitukhnovsky, “Luminescence confocal microscopy of 3D components of photonic integrated circuits fabricated by two-photon photopolymerization,” J. Sci.: Adv. Mater. Devices 7 (2), 100413 (2022). https://doi.org/10.1016/j.jsamd.2021.100413

ACKNOWLEDGMENTS

The authors are thankful to Dr. M. Arsenyev, Dr. E. Zhiganshina, and Prof. S. Chesnokov from the IOMC RAS for providing a special methacrylate dye (benzylidene cyclopentanone derivative dye) photocomposition with wide fabrication windows and strong property dependence on lithographical parameters, and to Dr. D.A. Chubich and D.D. Merkushev for discussion of the DLW fabrication principle.

Funding

Simulation and DLW lithography work, and LSCM investigations were supported by the Russian Science Foundation, project no. 22-79-10153. Technical and metrological evaluations were supported by the Ministry of Education and Science of the Russian Federation, grant no. 075-11-2021-086.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by M. Potapov

About this article

Cite this article

Matital, R.P., Kolymagin, D.A., Pisarenko, A.V. et al. Laser Scanning Confocal Microscopy for Analyzing Optical Characteristics and Morphology of an Aspherical Microlens Array. Phys. Wave Phen. 31, 217–222 (2023). https://doi.org/10.3103/S1541308X23040076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1541308X23040076