Abstract

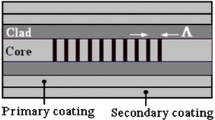

An apodized Fiber Bragg Grating (FBG) is designed to obtain minimal quantity of side lobes on the reflection spectrum for effective estimation of temperature sensitivity. Bare FBG cannot be implemented as a suitable option for sensing of temperature in a complex environment because it is composed of silica, which has a very low thermal expansion coefficient. Different kinds of materials having thermal expansion coefficients higher than silica are coated on designed apodized FBG to improve the sensitivity of temperature for the FBG. In this simulation work, titanium, nickel, gold, copper, silver, aluminum, lead, indium, polycarbonate, PMMA, and polyamide are coated on the apodized FBG to estimate the enhanced sensitivity for the temperature range of 25 to 75°C. The simulation results illustrated that the sensitivity of temperature for polyamide-coated FBG is highest than other coating materials.

Similar content being viewed by others

REFERENCES

N. Sabri, S. A. Aljunid, M. S. Salim, and S. Fouad, “Fiber optic sensors: Short review and applications,” in Recent Trends in Physics of Material Science and Technology, Ed. by F. Gaol, K. Shrivastava, and J. Akhtar (Springer-Verlag, Singapore, 2015), vol. 204, pp. 299–311. https://doi.org/10.1007/978-981-287-128-2_19

R. Kashyap, “Principles of optical fiber grating sensors,” in Fiber Bragg Gratings (Academic, 2010), chap. 10, pp. 441–502. https://doi.org/10.1016/b978-0-12-372579-0.00010-7

D. Gatti, G. Galzerano, D. Janner, S. Longhi, and P. Laporta, “Fiber strain sensor based on a π-phase-shifted Bragg grating and the Pound-Drever-Hall technique,” Opt. Express, 16 (3), 1945–1950 (2008). https://doi.org/10.1364/OE.16.001945

M.-C. Wu, R. H. Pater, and S. L. DeHaven, “Effects of coating and diametric load on fiber Bragg gratings as cryogenic temperature sensors,” Proc. SPIE 6933, 693303 (2008). https://doi.org/10.1117/12.775895

C.-S. Park, K.-I. Joo, S.-W. Kang, and H.-R. Kim, “A PDMS-coated optical fiber Bragg grating sensor for enhancing temperature sensitivity,” J. Opt. Soc. Korea 15 (4), 329–334 (2011). https://doi.org/10.3807/JOSK.2011.15.4.329

J. Jung, H. Nam, and B. Lee, “Fiber Bragg grating temperature sensor with controllable high sensitivity,” Proc. Conf. LEOS’98. 11th Ann. Meeting. IEEE Lasers and Electro-Opt. Soc. 1998 Ann. Meeting, Orlando, FL, USA, December 1–4, 1998 (IEEE, 1998), vol. 1, pp. 405–406. https://doi.org/10.1109/LEOS.1998.737901

Y. Li, Z. Hua, F. Yan, and P. Gang, “Metal coating of fiber Bragg grating and the temperature sensing character after metallization,” Opt. Fiber Technol. 15 (4), 391–397 (2009). https://doi.org/10.1016/j.yofte.2009.05.001

D. Sengupta, M. Sai Shankar, P. Saidi Reddy, R. L. N. Sai Prasad, K. S. Narayana, and P. Kishore, “An improved low temperature sensing using PMMA coated FBG,” Proc. SPIE 8311, 831103 (2011). https://doi.org/10.1117/12.904606

R. Rajini-Kumar, M. Suesser, K. G. Narayankhedkar, G. Krieg, and M. D. Atrey, “Performance evaluation of metal-coated fiber Bragg grating sensors for sensing cryogenic temperature,” Cryogenics 48 (3–4), 142–147 (2008). https://doi.org/10.1016/j.cryogenics.2008.02.007

C. Wen and Y. Li, “Effects of metal coating on the fiber Bragg grating temperature sensing characteristics,” J. Mod. Opt. 63 (8), 762–770 (2016). https://doi.org/10.1080/09500340.2015.1100341

V. Mishra, M. Lohar, and A. Amphawan, “Improvement in temperature sensitivity of FBG by coating of different materials,” Optik 127 (2), 825–828 (2016). https://doi.org/10.1016/j.ijleo.2015.10.014

P. Lu, L. Men, and Q. Chen, “Polymer-coated fiber bragg grating sensors for simultaneous monitoring of soluble analytes and temperature,” IEEE Sens. J. 9 (4), 340–345 (2009). https://doi.org/10.1109/JSEN.2009.2013499

H. N. Mandal and S. Sidhishwari, “Predictive Analysis on Apodized FBG for Quasi-Distributed Temperature-Strain Sensing,” Proc. 2022 IEEE Int. Conf. on Signal Processing and Communications (SPCOM), Bangalore, India, July 1–15, 2022 (IEEE, 2022), pp. 1–5 https://doi.org/10.1109/SPCOM55316.2022.9840764

S. S. A. Khan and M. S. Islam, “Determination of the best apodization function and grating length of linearly chirped fiber bragg grating for dispersion compensation,” J. Commun. 7 (11), 840–846 (2012). https://doi.org/10.4304/jcm.7.11.840-846

I. Yulianti, A. S. M. Supa’at, S. M. Idrus, and M. R. S. Anwar, “Design of fiber Bragg grating-based Fabry–Perot sensor for simultaneous measurement of humidity and temperature,” Optik 124 (19), 3919–3923 (2013). https://doi.org/10.1016/j.ijleo.2012.11.043

J. K. Sahota, N. Gupta, and D. Dhawan, “Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review,” Opt. Eng. 59 (6), 060901 (2020). https://doi.org/10.1117/1.oe.59.6.060901

S. Maske, P. B. Buchade, and A. D. Shaligram, “Characterization of fiber Bragg grating based on grating profile and apodization for sensor applications,” AIP Conf. Proc. 1989, 020028 (2018). https://doi.org/10.1063/1.5047704

E. A. Elzahaby, I. Kandas, and M. H. Aly, “Amendment performance of an apodized tilted fiber Bragg grating for a quasi-distributed-based sensor,” Appl. Opt. 56 (19), 5480–5488 (2017). https://doi.org/10.1364/AO.56.005480

F. M. Mustafa, A. F. Sayed, and M. H. Aly, “A reduced power budget and enhanced performance in a WDM system: A new FBG apodization function,” Opt. Quantum Electron. 54 (8), 471 (2022). https://doi.org/10.1007/s11082-022-03876-5

K. M. M. Prabhu, Window Functions and Their Applications in Signal Processing (CRC Press, Boca Raton, 2013). https://doi.org/10.1201/9781315216386

M. S. E. Djurhuus, B. Schmauss, A. T. Clausen, and D. Zibar, “Simultaneous temperature estimation of multiple gratings using a multi-layer neural network,” IEEE Photonics Technol. Lett. 32 (19), 1257–1260 (2020). https://doi.org/10.1109/LPT.2020.3019102

H. N. Mandal and S. Sidhishwari, “Sensitivity analysis of designed apodized fiber Bragg grating sensor using artificial neural network and tree-based models,” Results Opt. 10, 100343 (2023). https://doi.org/10.1016/j.rio.2022.100343

E. Chehura, C. C. Ye, S. E. Staines, S. W. James, and R. P. Tatam, “Characterization of the response of fibre Bragg gratings fabricated in stress and geometrically induced high birefringence fibres to temperature and transverse load,” Smart Mater. Struct. 13 (4), 888–895 (2004). https://doi.org/10.1088/0964-1726/13/4/027

ACKNOWLEDGMENTS

The authors are grateful to the Department of Electronics and Communication Engineering, Birla Institute of Technology Mesra, Ranchi for extending the research amenities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

The text was submitted by the author in English.

About this article

Cite this article

Mandal, H.N., Sidhishwari, S. Sensitivity Enhancement of Apodized Fiber Bragg Grating for Temperature Measurement. Phys. Wave Phen. 31, 252–262 (2023). https://doi.org/10.3103/S1541308X23040039

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1541308X23040039