Abstract

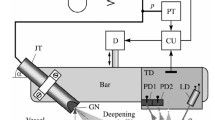

In this paper, the device for measuring the fluid pressure created by an impact is presented. The experimental results are presented that show the dependence of the force transferred by the fluid, which performs the pipe expansion, from the voltage on the capacitor.

Similar content being viewed by others

REFERENCES

Kablov, E.N., Innovative Developments of FSUE “VIAM” SSC of RF on Realization of “Strategic Directions of the Development of Materials and Technologies of Their Processing for the Period until 2030”, Aviatsionnye Materialy i Tekhnologii, 2015, no. 1 (34), pp. 3–33.

Khaimovich, I.N., Computer-Aided Design of Die Tooling for Large Parts of Airfoil Profiles Made of Aluminum Alloys, Izv. Vuz. Av. Tekhnika, 2020, vol. 63, no. 3, pp. 110–116 [Russian Aeronautics (Engl. Transl.), 2020, vol. 63, no. 3, pp. 489–496].

Belyaev, V.I., Koval’skii, V.N., Smirnov, G.V., and Chekan, V.A., High-Speed Deformation of Metals, in Vysokoskorostnaya deformatsiya metallov (High-Speed Deformation of Metals), Minsk: Nauka i Tekhnika, 1976.

Ukhvatov, N.N., Khusnullin, I.M., Kataev, Yu.P., Shaikhiev, F.G., Valiev, F.K., and Kuvshinov, P.I., RF Patent 2303690, Byull. Izobret., 2007, no. 21.

Rinehart, J.S. and Pearson, J., Explosive Working of Metals, Pergamon Press, 1963.

Impact Testing of Metals, Ed. Driscoll, D., West Conshohocken, PA: ASTM International, 1970.

Kataev, Yu.P., Dinamicheskoe plasticheskoe deformirovanie (Dynamic Plastic Deformation), Kazan: Izd. Kazan Av. Inst., 1982.

Knoepfel, H., Pulsed High Magnetic Fields, North-Holland, 1970.

Belyi, I.V., Fertik, S.M., and Khimenko, L.T., Spravochnik po magnitno-impulisnoi obrabotke metallov (Reference Book of Magneto Impulse Metal Processing), Khar’kov: Vishcha shkola, 1977.

Dubinin, G.M. and Avraamov, Yu.S., Konstruktsionnye provodnikovye i magnitnye materialy (Structural Conductive and Magnetic Materials), Moscow: Mashinostroenie, 1973.

Kataev, Yu.P., Kuvshinov, P.I., Pavlov, A.F., and Belonog, V.M., Magnitogidroimpul’snoe plasticheskoe deformirovanie metallov (Hydraulic Magnetic-Pulse Plastic Deformation of Metals), Moscow: Mashinostroenie, 1994.

Kuvshinov, P.I. and Kataev, Yu.P., Shock Wave Focusing in Magneto Hydro Impulse Loading, Izv. Vuz. Av. Tekhnika, 1983, vol. 26, no. 4, pp. 92–94 [Soviet Aeronautics (Engl. Transl.), 1983, vol. 26, no. 4, pp. 85–87].

Kataev, Yu.P., Calculation of Pipe Expansion and Sizing Process Parameters, Izv. Vuz. Av. Tekhnika, 2010, vol. 53, no. 3, pp. 57–59 [Russian Aeronautics (Engl. Transl.), 2010, vol. 53, no. 3, pp. 328–333].

Kataev, Yu.P., Kuvshinov, P.I., and Belonog, V.M., Determination of Loading Parameters in Magneto-Hydro-Pulse Forming, Izv. Vuz. Av. Tekhnika, 1987, vol. 30, no. 2, pp. 47–50 [Soviet Aeronautics (Engl. Transl.), 1987, vol. 30, no. 2, pp. 57–61].

Zvonov, S.Yu., Popov, I.P., and Shlyapugin, A.G., Peculiarities of the Process of Hollow Conical Parts Shaping from a Ring Blank, Izv. Vuz. Av. Tekhnika, 2010, vol. 53, no. 3, pp. 75–76 [Russian Aeronautics (Engl. Transl.), vol. 53, no. 3, pp. 358–361].

Dem’yanenko, E.G. and Popov, I.P., Study of Thin-Walled Parts Shaping Process Based on Flanging and Embossing, Izv. Vuz. Av. Tekhnika, 2016, vol. 59, no. 2, pp. 114–118 [Russian Aeronautics (Engl. Transl.), vol. 59, no. 2, pp. 277–282].

Dem’yanenko, E.G. and Popov, I.P., Limits of Flanging Process Feasibility to Create Thin-Wall Conical Shells, Izv. Vuz. Av. Tekhnika, 2012, vol. 55, no. 4, pp. 60–62 [Russian Aeronautics (Engl. Transl.), vol. 55, no. 4, pp. 408–412].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Aviatsionnaya Tekhnika, 2021, No. 3, pp. 195 - 199.

About this article

Cite this article

Kataev, Y.P., Kuvshinov, P.I. Pressure Measurement during the Pipe Expansion Using the Magneto Hydro Impulse Method. Russ. Aeronaut. 64, 571–576 (2021). https://doi.org/10.3103/S1068799821030272

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068799821030272