Abstract

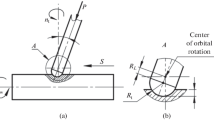

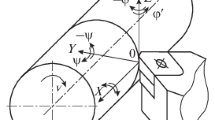

In the hybrid burnishing of holes in LS59-1 brass billets, for which grinding is not applicable, experiments are conducted to assess the dependence of the accuracy on the microgeometry of the tool’s working surfaces and the composition of the lubricant ensuring wear-free operation of Garkunov–Kragelskii type.

Similar content being viewed by others

REFERENCES

Rozenberg, A.M., Rozenberg, O.A., Posvyatenko, E.K., et al., Raschet i proektirovanie tverdosplavnykh deformiruyushchikh protyazhek i protsessa protyagivaniya (Calculation and Design of Carbide Deforming Broaches and the Broaching Process), Kiev: Naukova Dumka, 1978.

Proskuryakov, Yu.G., Romanov, V.N., and Isaev, A.N., Ob”emnoe dornovanie otverstii (Volumetric Mandrel of Holes), Moscow: Mashinostroenie, 1984.

Shchedrin, A.V., Kostryukov, A.A., and Chikhache-va, N.Yu., Artificial technological intelligence as the ideological basis of the generalized system of materials processing methods, Uproch. Tekhnol. Pokryt., 2015, no. 6, pp. 20–26.

Shchedrin, A.V., Ignatkin, I.Yu., and Chikhache-va, N.Yu., Systemic formation of information databases of characteristics of processing methods for implementation of algorithmic procedures of artificial technological intelligence, Uproch. Tekhnol. Pokryt., 2020, vol. 16, no. 10, pp. 444–451.

Shchedrin, A.V., Tanengol’ts, A.B., Egorova, Z.I., et al., Tribological concept of system analysis-synthesis of combined methods of deformation-cutting processing, Tekh. Mashinostr., 2001, no. 4 (32), pp. 53–59.

Shchedrin, A.V., Ignatkin, I.Yu., Bugaev, A.M., et al., Study of power dynamics characteristics of combined mandrelling methods of holes by regular surface microgeometry tool, Uproch. Tekhnol. Pokryt., 2020, vol. 16, no. 8, pp. 360–365.

Shchedrin, A.V., Bekaev, A.A., Ignatkin, I.Yu., et al., Effect of composition of metal-cladding lubricant and its application technology on contact characteristics of combined hole mandrelling methods, Uproch. Tekhnol. Pokryt., 2020, vol. 16, no. 11, pp. 504–510.

Garkunov, D.N., Mel’nikov, E.L., Babel’, V.G., et al., Tribologiya na osnove samoorganizatsii (Tribology Based on Self-Organization), Saarbrucken: Lambert Academic, 2015.

Shchedrin, A.V., Ignatkin, I.Yu., and Chikhache-va, N.Yu., Study of variation patterns in sliding friction coeffi cient in innovative methods of combined hole mandrelling, Uproch. Tekhnol. Pokryt., 2020, vol. 16, no. 4, pp. 150–155.

Shchedrin, A.V., Ulyanov, V.V., Bekaev, A.A., and Chikhacheva, N.Yu., Efficient hole broaching with regularized surface microgeometry of the deforming elements, Russ. Eng. Res., 2009, vol. 29, no. 9, pp. 911–915.

Shchedrin, A.V., Aleshin, V.F., Mel’nikov, E.L., et al., Study of formation regularities of surface layer quality parameters during cutting on prestrained layer in methods of combined hole burnishing, Remont, Vosstan., Modern., 2020, no. 1, pp. 23–28.

Sergeev, E.S., Zinin, M.A., Gavrilov, S.A., et al., Influence of the angle of deflection member surfaces affect the performance of the combined methods of suturing (drawing) of the holes, Uproch. Tekhnol. Pokryt., 2015, no. 3, pp. 20–24.

Shchedrin, A.V., Aleshin, V.F., Bugaev, A.M., et al., Technological capabilities of combined mandrelling method of holes by acting surfaces helical geometry tools, Uproch. Tekhnol. Pokryt., 2019, vol. 15, no. 8, pp. 342–347.

Vorontsov, A.L., Industrial testing of the results of a combined reduction-mandrelling process researching, Kuznechno-Shtamp. Proizvod. Obrab. Mater. Davlen., 2017, no. 9, pp. 3–10.

Shchedrin, A.V., Aleshin, V.F., Bekaev, A.A., and Chikhacheva, N.Yu., Hybrid burnishing of cylindrical workpieces with a modified hole surface, Russ. Eng. Res., 2020, vol. 40, no. 10, pp. 852–856.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Chikhacheva, N.Y., Shchedrin, A.V., Bekaev, A.A. et al. Influence of the Tool’s Surface Microgeometry and the Lubricant Composition on Hole Precision in Hybrid Burnishing. Russ. Engin. Res. 42, 781–786 (2022). https://doi.org/10.3103/S1068798X2208010X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X2208010X