Abstract

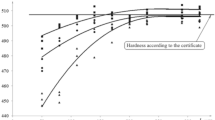

Pipe ball mills are widely used for coarse and fine crushing in producing construction materials. It is a priority to decrease their energy consumption. A mill with dimensions D × L = 3 × 8 m may be used for preliminary crushing in a cylindrical internal classification system, so as to ensure effective coarse milling. The goal is to determine the state of such a device prior to maintenance, after abrasive wear of its components. The magnitude and direction of the forces on the device from the balls and the material being crushed are determined. The most loaded elements are identified: reinforcing lining plates of thickness 0.04 mm. Their stress state is studied with decrease in thickness on account of abrasive wear. The possibility of operating the device to 40% wear of its lining plates is established. Thereafter, repairs are necessary.

Similar content being viewed by others

REFERENCES

Bogdanov, V.S., Sharapov, R.R., and Bazhanova, O.I., Effect of suction in closed cycle ball mills on the kinetics of the grinding process, Tsement Ego Primen., 2012, no. 5, pp. 78–81.

Bogdanov, V.S., Bogdanov, D.V., and Semikopenko, I.A., Protsessy v proizvodstve stroitel’nykh materialov (Processes in the Production of Building Materials), Staryi Oskol: TNT, 2018.

Bogdanov, V.S., Energy exchange devices for ball drum mills, Steklo Keram., 1985, no. 6, pp. 19–21.

Duda, W.H., Cement Data Book, Wiesbaden, Berlin: Bauverlag GmbH, 1985.

Khanin, S.I., Solodovnikov, D.N., and Lebakh, A.V., Determining the loads acting onto a cylindrical classifier of a globe mill, IOP Conf. Ser.: Mater. Sci. Eng., 2019, vol. 560, no. 1, art. ID 012066.

Khanin, S.I., Kaidash, V.V., Chalov, A.A., Solodovnikov, D.N., and Khanina, O.S., RF Patent 2236298, Byull. Izobret., 2004, no. 26.

Sapozhnikov, M.Ya., Mekhanicheskoe oborudovanie predpriyatii stroitel’nykh materialov, izdelii i konstruktsii (Mechanical Equipment of Enterprises of Construction Materials, Products and Structures), Moscow: Vysshaya Shkola, 1971.

Il’evich, A.P., Mashiny i oborudovanie dlya zavodov po proizvodstvu keramiki i ogneuporov (Machines and Equipment for Plants Producing Ceramics and Refractories), Moscow: Vysshaya Shkola, 1979.

Kryukov, D.K., Futerovki sharovykh mel’nits (Ball Mills Linings), Moscow: Mashinostroenie, 1965.

Funding

This work was supported within the Priority 2030 program at Shukhov Belgorod State Technological University, using equipment at the University’s high-technology center.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they has no conflict of interest.

Additional information

Translated by B. Gilbert

About this article

Cite this article

Khanin, S.I., Zybin, R.V., Ryabukhin, V.V. et al. Stress State of Internal Classifying Modules in a Pipe Ball Mill Prior to Maintenance. Russ. Engin. Res. 42, 517–519 (2022). https://doi.org/10.3103/S1068798X22050148

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X22050148