Abstract

Arc ignition and combustion are investigated in the creation of hard composite coatings by vibroarc carbide surfacing. The electric field strength in vibroarc carbide surfacing may be increased by minimizing the acceleration of the carbon electrode in vibration. The best conditions of vibroarc carbide surfacing are determined.

Similar content being viewed by others

REFERENCES

Artem’ev, A.A., Sokolov, G.N., Zorin, I.V., et al., Formation of structure in clad abrasion-resistant alloys of the Fe–Cr–C–Mo–Ni–Ti–B system under the effect of ultrafine particles of titanium nitride, Met. Sci. Heat Treat., 2020, vol. 61, pp. 724–730. https://doi.org/10.1007/s11041-020-00490-8

Stolin, A.M., Bazhin, P.M., Mikheyev, M.V., et al., Deposition of protective coatings by electric arc cladding with SHS electrodes, Weld. Int., 2015, vol. 29, no.8, pp. 657–660.

Leont’ev, L.B., Shapkin, N.P., Leont’ev, A.L., Shkuratov, A.L., et al., The control of forming of compositional wear resistance, metal-ceramic coatings on the surfaces of friction of details, Fund. Issled., 2012, no. 11-3, pp. 630–635.

Ivanov, V.I. and Burumkulov, F.K., Hardening of objects and the increase of their lifetime by the electrospark method: The object classification and the specific features of the technology, Surf. Eng. Appl. Electrochem., 2010, vol. 46, no. 5, pp. 416–423. https://doi.org/10.3103/S1068375510050042

Dorokhov, A.S., Aulov, V.F., Lyalyakin, V.P., et al., Increasing the wear resistance of coatings obtained by HDPE boration with modification of Fe–Al and Ni–Al systems with intermetallides, Tekhnol. Mashinostr., 2020, no. 2, pp. 23–33.

Ageev, E.V. and Sabel’nikov, B.N., Wear-resistant tungsten-free solid-alloy powder materials for restoring worn car, Mir Transport. Tekhnol. Mash., 2020, no. 1 (68), pp. 11–17.

Vainerman, A.E. and Belyaev, N.V., Argon-arc facing of steel with powders on the basis of tungsten carbide to obtain a wear-resistant coating, Vopr. Materialoved., 2002, no. 2 (30), pp. 43–46.

Golyshev, A.A., Orishich, A.M., and Filippov, A.A., Formation of B4C–Ti–6Al–4V cermet coatings by the method of SLM, Met. Sci. Heat Treat., 2021, vol. 62, pp. 696–700. https://doi.org/10.1007/s11041-021-00624-6

Fomin, V.M., Golyshev, A.A., Kosarev, V.F., et al., Deposition of cermet coatings on the basis of Ti, Ni, WC, and B4C by cold gas dynamic spraying with subsequent laser irradiation, Phys. Mesomech., 2020, vol. 23, pp. 291–300. https://doi.org/10.1134/S1029959920040025

Leont’ev, L.B., Shapkin, N.P., Leont’ev, A.L., and Toklikishvili, A.G., Investigation of the effect of process parameters forming cermet coating on the tribological properties of the friction unit, Metalloobrabotka, 2012, no. 2 (68), pp. 28–30.

Gal’chenko, N.K., Samartsev, V.P., Belyuk, S.I., and Gal’chenko, V.G., Features of the formation of the structure and properties of metal-ceramic coatings obtained nitride-plasma technology, Probl. Chern. Metall. Materialoved., 2010, no. 1, pp. 60–64.

Rudenskaya, N.A., Shveikin, G.P., and Guletskii, V.A., Effects of hardening of metal-ceramic coatings in the process of their formation, Dokl. Akad. Nauk, 2010, vol. 433, no. 6, pp. 776–779.

Gal’chenko, N.K., Dampilon, B.V., and Belyuk, S.I., Formation of structure and properties of metal-ceramics composites based on titanium carbonitrides, Fiz. Mezomekh., 2004, vol. 7, no. S1-2, pp. 181–184.

Gal’chenko, N.K., Samartsev, V.P., Kashina, E.E., et al., Peculiarities of structure formation and properties of metal-ceramic coatings of Al2O3–CrxNy and Al2O3–Mo2 systems, Fiz. Mezomekh., 2004, vol. 7, no. S1-2, pp. 177–180.

Sharifullin, S.N., Adigamov, N.R., Kudryashova, E.Yu., et al., Tribological studies of surfaces of 65G steel parts hardened by plasma methods, Tekh. Serv. Mash., 2019, no. 3 (136), pp. 120–127.

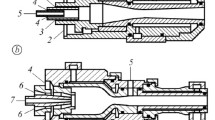

Kolomeychenko, A.V., Titov, N.V., Vinogradov, V.V., et al., The microstructure of composite cermet coatings produced by carbo-vibroarc surfacing, Weld. Int., 2017, vol. 31, no. 9, pp. 739–742.

Khamzin, A.V., Slobodchikov, D.A., and Semeshin, P.A., Carbo-vibro-arc hardening is a promising method of increasing the wear resistance of car parts, Materialy VIII mezhdunarodnoi nauchno-tekhnicheskoi konferentsii “Sovremennye avtomobil’nye materialy i tekhnologii” (Proc. 8th Int. Sci.–Tech. Conf. “Modern Automotive Materials and Technologies”), Kursk, 2016, pp. 418–424.

Kolomeichenko, A.V., Titov, N.V., and Bagrintsev, O.O., Influence of multicomponent paste composition on physical and mechanical properties of metal-ceramic coatings obtained at carbo-vibro-arc hardening, Vestn. Bashkirsk. Gos. Agrar. Univ., 2019, no. 2 (50), pp. 121–124.

Lyalyakin, V.P., Solov’ev, S.A., and Aulov, V.F., The state and prospects of hardening and restoration of parts of tillage machines by welding and surfacing methods, Tr. GOSNITI, 2014, vol. 115, pp. 96–104.

Titov, N.V., Kolomeichenko, A.V., Bazhin, P.M., et al., Structural characteristics of composite metal-ceramic coatings formed using iron-based multicomponent pastes, Kompoz. Nanostrukt., 2019, vol. 11, no. 2, pp. 64–68.

Nerovniy, V.M., Konovalov, A.V., Yakushin, B.F., et al., Teoriya svarochnykh protsessov (Theory of Welding Processes), Nerovniy, V.M., Ed., Moscow: Mosk. Gos. Tekh. Univ. im. N.E. Baumana, 2016.

Titov, N.V., Kolomeichenko, A.V., Basinyuk, V.L., et al., Thermophysical characteristics of multicomponent pastes for application of hardening coatings, Polym. Sci., Ser. D, 2021, vol. 14, pp. 387–391. https://doi.org/10.1134/S1995421221030321

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Titov, N.V., Kolomeychenko, A.V., Ageev, E.V. et al. Application of Composite Coatings by Vibroarc Carbide Surfacing. Russ. Engin. Res. 42, 355–359 (2022). https://doi.org/10.3103/S1068798X2204030X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X2204030X