Abstract

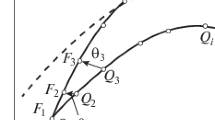

The quality of CNC machines and their control systems is assessed in terms of the contour accuracy, consisting of two components: the accuracy in sending the signal confirming that the working component has reached the specified coordinate; and the accuracy in executing the stop command, given the inertia of the actuators. Recommendations are made regarding the selection of the device for monitoring the motion of the working components in a CNC machine with a gapless gear transmission and a torsional motor. If the required positional accuracy is low, it is acceptable to disregard the error in the gear ratio of the mechanical transmission between the sensor and the guide screw (or any other device converting rotation into linear motion). When using a device for monitoring the motion of the working components in a CNC machine, the adjustment of the sensor at the center of the scale interval should be as precise as possible.

Similar content being viewed by others

REFERENCES

Demidov, S.V., Avdushev, S.S., Lubnikov, A.M., et al., Elektromekhanicheskie sistemy upravleniya tyazhelymi metallorezhushchimi stankami (Electromechanical Control Systems of Heavy Metal-Cutting Mahcines), Demidov, S.V., Ed., Leningrad: Mashinostroenie, 1986.

GOST (State Standard) 27843–88: Metal Cutting Machine Tools. Test Methods for Positioning Accuracy, Moscow: Izd. Standartov, 1990.

Liberman, Ya.L., Reducing the quantization error in encoder position sensors, Stanki Instrum., 1973, no. 8, pp. 18–19.

Liberman, Y.L., Reduction of quantization error in position encoders, IOP Conf. Ser.: Mater. Sci. Eng., 2020, vol. 709, art. ID 022062.

Anur’ev, V.I., Spravochnik konstruktora-mashinostroitelya (Handbook of Machine Engineer), Moscow: Mashinostroenie, 1979, vol. 2.

Gusev, I.T., Eliseev, V.G., and Maslov, A.A., Ustroistva chislovogo programmnogo upravleniya (Numerical Control Devices), Moscow: Vysshaya Shkola, 1986.

Baranov, G.L., Raschet detalei mashin: uchebnoe posobie (Calculation of Machine Parts: Manual), Yekaterinburg: Ural. Gos. Tekh. Univ.-Ural. Politekh. Inst., 2005.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Liberman, Y.L., Gorbunova, L.N. Selection of Positioning Devices for the Components of CNC Machines. Russ. Engin. Res. 41, 1067–1070 (2021). https://doi.org/10.3103/S1068798X21110204

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21110204