Abstract

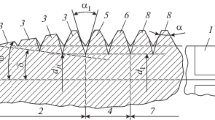

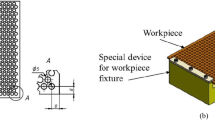

In the manufacture of internal thread by taps, the quality may be improved by special preparation of the three tap sections with different functions. The sections are subjected to differential magnetic–abrasive finishing on a CNC system, taking account of their specific characteristics and functions (roughing, semifinishing, and finishing, respectively). The use of such taps decreases the surface roughness Ra of internal threads in 12Cr18N10T stainless steel by a factor of 1.3–3.

Similar content being viewed by others

REFERENCES

Fedorov, V.P., Gorlenko, O.A., et al., Tekhnologicheskoe obespechenie i povyshenie ekspluatatsionnykh svoistv detalei i ikh soedinenii (Technological Support and Improvement of the Operational Properties of Parts and Their Joints), Suslov, A.G., Ed., Moscow: Mashinostroenie, 2006.

Yakushev, A.I., Mustaev, R.Kh., and Mavlyutov, R.R., Povyshenie prochnosti i nadezhnosti rez’bovykh soedinenii (Improving the Strength and Reliability of Threaded Connections), Moscow: Mashinostroenie, 1979.

Bez”yazychnyi, V.F., Scherek, M., Pervov, M.L., et al., The effect of temperature on the ability of metals to accumulate energy during plastic deformation, Zap. Gorn. Inst., 2019, vol. 235, pp. 55–59.

Birger, I.A. and Iosilevich, G.B., Rez’bovye i flantsevye soedineniya (Threaded and Flanged Joints), Moscow: Mashinostroenie, 1990.

Khalimonenko, A.D., Timofeev, D.Y., and Golikov, T.S., Cutting tool for turning large workpieces, J. Phys.: Conf. Ser., 2019, vol. 1399, art. ID 44082.

Baron, Yu.M., Influence of the condition of the blade edges on the efficiency of cutting tools, Instrum. Tekhnol., 1997, no. 5, pp. 1–11.

Matveev, V.V., Narezanie tochnykh rez’b (Cutting of Precise Threads), Moscow: Mashinostroenie, 1978.

Maiboroda, V.S., Slobodyanyuk, I.V., and Dzhulii, D.Yu., Magnitno-abrazivnaya obrabotka detalei slozhnoi formy (Magnetic Abrasive Machining of Complex Parts), Zhitomir: Ruta, 2017.

Baljinder, S. and Charanjit, S., Optimization of magnetic abrasive finishing parameters during finishing of brass tube, Int. Res. J. Eng. Technol., 2015, vol. 2, no. 4, pp. 1810–1817.

Dhirendra, K. and Singh, V.K., Parametric study of magnetic abrasive finishing process, J. Mater. Process. Technol., 2004, vol. 149, pp. 22–29.

Jayswal, S.C., Jain, V.K., and Dixit, P.M., Modeling and simulation of magnetic abrasive finishing process, Int. J. Adv. Manuf. Technol., 2005, vol. 26, pp. 477–490.

Maksarov, V.V. and Keksin, A.I., RF Patent 2626124, Byull. Izobret., 2017, no. 21.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Maksarov, V.V., Vasin, S.A. & Keksin, A.I. Improving Internal Threaded Surfaces in Highly Loaded Components. Russ. Engin. Res. 41, 944–947 (2021). https://doi.org/10.3103/S1068798X21100191

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21100191