Abstract

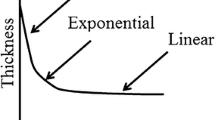

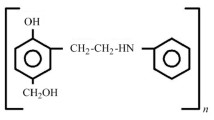

The influence of matrix geometry on the crimping of bronze bushings is investigated. For successful crimping, the plastic reduction should be no more than 10–15%. In addition, the intake angle of the crimping matrix should be 25°–45°. Larger angles greatly impair the process. The taper of the matrix’s approach section has little influence on the limiting bushing compression. Increase in frictional coefficient likewise has no significant effect on the deformation.

Similar content being viewed by others

REFERENCES

Bondareva, G.I. and Leonov, O.A., The construction of a modern system of quality at the enterprises of technical service, Sel. Mekhanizator, 2017, no. 8, pp. 34–35.

Erokhin, M.N., Ensuring the quality of reparation of agricultural machines at the present stage, Vestn. Mosk. Gos. Agroinzh. Univ., 2005, no. 1, pp. 9–12.

Erokhin, M.N., Assessing the relative interchangeability in joints with preload, Russ. Eng. Res., 2020, vol. 40, no. 6, pp. 469–472.

Leonov, O.A., Shkaruba, N.Zh., Vergazova, Yu.G., et al., Quality control in the machining of cylinder liners at repair enterprises, Russ. Eng. Res., 2020, vol. 40, no. 9, pp. 726–731.

Leonov, O.A. and Shkaruba, N.Zh., Development of the management system for metrological assurance of measurements, J. Phys.: Conf. Ser., 2020, vol. 1515, art. ID 032010.

Leonov, O.A. and Shkaruba, N.Zh., The results of economic optimization of the choice of measuring tools in quality control of technological processes in reparation industry, Vestn. Mosk. Gos. Agroinzh. Univ., 2007, no. 5 (25), pp. 109–112.

Bondareva, G.I., Application of technical and economic criteria for choose of measuring means in reparation industry, Ekon. S-kh. Pererab. Predpr., 2008, no. 1, pp. 53–55.

Bondareva, G.I., The efficiency of the implementation of the quality system at the enterprises of the technical service in the agro-industrial complex, Sel. Mekhanizator, 2016, no. 4, pp. 34–35.

Bondareva, G.I., Theoretical basis for choose of rational methods for reparation of parts, Sel. Mekhanizator, 2019, no. 5, pp. 38–39.

Toigambaev, S.K. and Romanyuk, S.N., Restoration of the durability of bronze mufts for agricultural and transport vehicles, Mezhdunar. Tekh.-Ekon. Zh., 2013, no. 4, pp. 67–70.

Toigambaev, S.K., Dimensional analysis of sliding bearings during compression, Vestn. Mosk. Gos. Agroinzh. Univ., 2013, no. 2 (58), pp. 38–40.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Golinitskii, P.V., Leonov, O.A., Shkaruba, N.Z. et al. Matrix Geometry in Crimping of Bronze Bushings. Russ. Engin. Res. 41, 892–895 (2021). https://doi.org/10.3103/S1068798X21100099

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21100099