Abstract

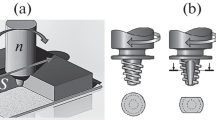

Industrial design methods are outlined for friction stir welding processes. These methods are based on parametric modeling of a digital twin of the tool, with associative relations between the geometric and physicochemical parameters in the manufacturing chains of the structure and tool. The results of parametric numerical modeling of the tool with variation in its geometry are presented. In simulation, iterative model relations are organized in the design chain for the machining conditions and the CNC control programs.

Similar content being viewed by others

REFERENCES

Klimenko, Yu.V., USSR Inventor’s Certificate no. 195846, 1967.

Thomas, W.M., et al., UK Patent GB92/02203, 1991.

Mishra, R., Mahoney, M.W., Sato, Y., et al., Friction Stir Welding and Processing VII, New York: Springer-Verlag, 2013.

Boitsov, A.G., Kuritsyn, D.N., Siluyanova, M.V., and Kuritsyna, V.V., Friction stir welding in the aerospace industry, Russ. Eng. Res., 2018, vol. 38, no. 12, pp. 1029–1033.

Kuritsyn, D.N., Denisov, L.V., Siluyanova, M.V., and Kuritsyna, V.V., Tool for friction stir welding in the aerospace industry, Russ. Eng. Res., 2020, vol. 40, no. 3, pp. 245–248.

Makarov, E.L., Korolev, S.A., Shtrikman, M.M., and Kashchuk, N.M., Modeling of thermal processes in friction welding, Svarka Diagn., 2010, no. 3, pp. 21–25.

Lyushchinskii, A.V., Baranov, A.A., Boitsov, A.G., Pleshakov, A.S., Kachko, V.V., and Kuritsyn, D.N., RF Patent 2621514, 2017.

Boitsov, A.G., Pleshakov, A.S., Siluyanova, M.V., and Baranov, A.A., Friction stir welding of M1 copper alloy in the production of power equipment, Russ. Eng. Res., 2020, vol. 40, no. 3, pp. 249–252.

Denisov, L.V., Siluyanova, M.V., Kuritsyna, V.V., and Kuritsyn, D.N., Uniform electrospark surface hardening of airplane-engine parts, Russ. Eng. Res., 2020, vol. 40, no. 3, pp. 270–273.

Kuritsyn, D.N., Siluyanova, M.V., Denisov, L.V., et al., Durable tools for friction stir welding of high-temperature airplane-engine components, Russ. Eng. Res., 2020, vol. 40, no. 6, pp. 497–500.

Funding

Financial support was provided by the Russian President as motivation for young scientists (grant MK-944.2020.8).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Kuritsyn, D.N., Kuritsyna, V.V. & Siluyanova, M.V. Digital Twins in the Design of Tools for Friction Stir Welding. Russ. Engin. Res. 41, 357–359 (2021). https://doi.org/10.3103/S1068798X21040146

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21040146