Abstract

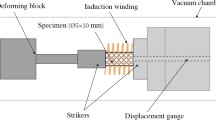

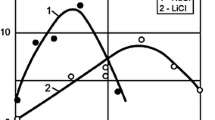

The fundamental kinetic difference between the transformation of high-speed steel on heating by high-frequency inductive current and on quenching in salt baths is considered. In heating by high-frequency current, the high temperature at the carbide–matrix boundary permits more complete carbide solution in the austenite. That improves tool quality.

Similar content being viewed by others

REFERENCES

Smol’nikov, E.A., Termicheskaya i khimiko-termicheskaya obrabotka instrumenta v solyanykh vannakh (Thermal and Chemical-Thermal Treatment of Tool in Salt Baths), Moscow: Mashinostroenie, 1989.

Geller, Yu.A., Instrumental’nye stali (Tool Steels), Moscow: Metallurgiya, 1983.

Kukolev, V.V., Primenenie vysokochastotnogo nagreva pri zakalki rezhushchego instrumenta (Application of High-Frequency Heating in Cutting Tool Hardening), Moscow: Eksp. Nauchno-Issled. Inst. Metallorezh. Stankov, 1962.

Elektrotermicheskoe oborudovanie: Spravochnik (Electrothermal Equipment: Handbook), Al’tgauzen, A.P., Ed., Moscow: Energiya, 1980.

Saltykov, S.A., Stereometricheskaya metallografiya (Stereometric Metallography), Moscow: Metallurgiya, 1976.

Baranova, L.V. and Demina, E.L., Metallograficheskoe travlenie metallov i splavov (Metallographic Etching of Metals and Alloys), Moscow: Metallurgiya, 1986.

Adaskin, A.M., Andzhyus, P.A., Buzelis, V.I., and Makhmudov, A.Yu., Specific heat treatment of R6M5 steel, Stanki Instrum., 1973, no. 7, pp. 31–33.

Geveling, N.V., Poverkhnostnaya elektrotermoobrabotka (Surface Electrothermal Treatment), Leningrad: Krasnyi Pechatnik, 1936.

Svoistva elementov. Spravochnik (Properties of Elements: Handbook), Drits, M.E., Ed., Moscow: Metallurgiya, 1983.

Samsonov, G.V., Tugoplavkie soedineniya: Spravochnik po svoistvam i primeneniyu (Refractory Compounds: Handbook on Properties and Application), Moscow: Gos. Nauchno-Tekh. Izd. Chern. Tsvetn. Metall., 1953.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Adaskin, A.M. Inductive Heating in the Quenching of High-Speed Steel Tools. Russ. Engin. Res. 41, 231–235 (2021). https://doi.org/10.3103/S1068798X21030035

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21030035