Abstract

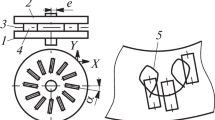

A model is proposed for the elastic deformation of the machining system in milling the flow section of a monowheel. The relation between blade deformation and the milling force is established for each point of the mill trajectory. The influence of the workpiece and tool deformation on the precision of the monowheel’s aerodynamic profile is established.

Similar content being viewed by others

REFERENCES

Poletaev, V.A., Tekhnologiya avtomatizirovannogo proizvodstva lopatok gazoturbinnykh dvigatelei (Technology of Automated Production of the Blades of Gas Turbine Engines), Moscow: Mashinostroenie, 2006.

Poletaev, V.A., Volkov, D.I., and Kliment’ev, A.V., A universal method for processing of the flow path of GTE impellers, Vestn. Rybinsk. Gos. Aviats. Tekhnol. Akad. im. P.A. Solov’eva, 2010, vol. 1 (16), pp. 116–120.

Krylov, V.N., Poletaev, V.A., and Volkov, D.I., RF Patent 2247011, Byull. Izobret., 2005, no. 28.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Volkov, D.I., Kozhina, S.M. Improving the Precision of Monowheel Manufacture. Russ. Engin. Res. 40, 1103–1106 (2020). https://doi.org/10.3103/S1068798X20120497

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X20120497