Abstract

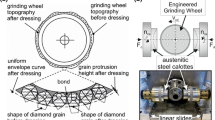

The finishing of the parabolic surface of a hard-alloy punch by a diamond wheel with a multilayer composite electrolytic coating is considered. The cutting forces on an individual grain are calculated. Cutting conditions corresponding to long tool life and the required surface quality are identified.

Similar content being viewed by others

REFERENCES

Yin, L., Vancoille, E., Ramesh, K., et al., Ultraprecision grinding of tungsten carbide for spherical mirrors, J. Eng. Manuf., 2004, vol. 218, no. 4, pp. 419–429.

Suzuki, H., Furuki, T., Okadaan, M., et al., Precision grinding of structured tungsten carbide mold, Adv. Mater. Res., 2012, vol. 497, pp. 15–19.

Yan, Q., Syoji, K., Tanaka, K., et al., Analyses of grinding force characteristic on high speed creep feed grinding tungsten carbide, Proc. Third Int. Conf. on Abrasive Technology “Abrasive Technology: Current Development And Applications,” Singapore: World Scientific, 1999.

Wenfeng, D., Linke, B., Yejun, Z., et al., Review on monolayer CBN superabrasive wheels for grinding metallic materials, Chin. J. Aeronaut., 2017, vol. 30, no. 1, pp. 109–134.

Yuan, H.-P., Guo, D.-M., and Gao, H., Electrolytic dressing mechanism of electroplated multilayer abrasive wheel with nickel-cobalt alloy, J. Dalian Univ. Technol., 2012, vol. 52, no. 2, pp. 197–202.

Venkata Rao, R., Advanced Modeling and Optimization of Manufacturing Processes: International Research and Development, New York: Springer-Verlag, 2010.

Balykov, A.V., Formoobrazovanie otverstii v detalyakh iz nemetallicheskikh materialov almaznym instrumentom (Hole Drilling in the Parts from Nonmetallic Materials by Diamond Tool), Moscow: Mosk. Gos. Tekh. Univ., Stankin, 2007.

Balykov, A.V., The efficiency of machining of holes in parts from brittle nonmetallic materials based by diamond drilling, Doctoral (Eng.) Dissertation, Moscow, 2004.

Korolev, A.V. and Tyurin, A.N., Calculation of the retention strength of the abrasive grain by the bond, Vestn. Mosk. Gos. Tekh. Univ. im. N.E. Baumana, 2008, no. 3, pp. 100–109.

Shavva, M.A., Calculation of cutting forces for diamond grinding of brittle optical materials, Izv. Vyssh. Uchebn. Zaved., Mashinostr., 2017, no. 2 (683), pp. 61–69.

Khudobin, L.V. and Unyanin, A.N., Minimizatsiya zasalivaniya shlifoval’nykh krugov (Minimization of Greasing of Grinding Wheels), Ulyanovsk: Ul’yanovsk. Gos. Tekh. Univ., 2007.

Verzhanskii, A.P. and Dubinin, P.I., Wear of diamond grains during elastic grinding of natural stone, Gorn. Inf.-Anal. Byull., 2009, no. 11, p. 74.

Kragel’skii, I.V., Dobychin, M.N., and Kambalov, V.S., Osnovy raschetov na trenie i iznos (Basic Calculations for Friction and Wear), Moscow: Mashinostroenie, 1977.

Kreimer, G.S., Prochnost’ tverdykh splavov (Strength of Solid Alloys), Moscow: Metallurgiya, 1966.

Bakhvalov, G.T., Novaya tekhnologiya elektroosazhdeniya metallov (reversirovanie toka v gal’vanostegii) (New Technology of Metal Electrodeposition (Current Reversal in Electroplating)), Moscow: Metallurgiya, 1966.

Shavva, M.A. and Grubyi, S.V., The relationship between wheel wear and cutting forces during diamond grinding, Nauka Obraz., 2014, no. 11, pp. 137–156.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Shavva, M.A., Grubyi, S.V. Diamond Grinding of Hard-Alloy Punches Using Wheels with a Multilayer Composite Electrolytic Coating. Russ. Engin. Res. 40, 826–832 (2020). https://doi.org/10.3103/S1068798X2010024X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X2010024X