Abstract

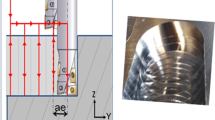

Attention focuses on the selection of a removable polyhedral insert with recommended geometry of the cutting element, when the tool material meets the requirements of intermittent cutting. Shaping of the cutter’s front surface to intensify machining is also considered.

Similar content being viewed by others

REFERENCES

Muzykant, Ya.A., Arpaz, Ya., Volosova, M.A., et al., Instrumental’shchik: Entsiklopedicheskii spravochnik-katalog (Tool Engineer: Encyclopedic Handbook-Catalogue), Moscow: Nauka i Tekhnologii, 2009, vol. 1.

Andreev, V.N., Borovskii, G.V., and Grigor’ev, S.N., Instrument dlya vysokoproizvoditel’nogo i ekologicheski chistogo rezaniya (A Tool for High-Performance and Ecologically Pure Cutting), Moscow: Mashinostroenie, 2010.

Özel, T., Modeling of hard part machining: effect of insert edge preparation in CBN cutting tools, J. Mater. Process. Technol., 2003, vol. 141, no. 2, pp. 284–293.

Grzesik, W., Zak, K., and Chudy, R., Influence of tool nose radius on the cutting performance and surface finish during hard turning with CBN cutting tools, J. Mach. Eng., 2017, vol. 17, no. 2, pp. 56–64.

Ståhl, J.E., Metal Cutting: Theories and Models, Lund: Lund Univ., 2012.

Gorodetskii, Yu.I., Budankov, A.S., and Komarov, V.N., A system for experimental studies of the dynamics of the process of cutting metal, J. Mach. Manuf. Reliab., 2008, vol. 37, no. 1, pp. 68–73.

Zhou, J., Mechanical Load Identification for Spontaneous Tool Failure Monitoring, Lund: Lund Univ., 1996.

Kudryashov, E.A., Smirnov, I.M., Yatsun, E.I., and Pavlov, E.V., Improved tools for the turning of complex surfaces, Russ. Eng. Res., 2018, vol. 38, no. 3, pp. 223–228.

Kudryashov, E.A. and Smirnov, I.M., Rational conditions for brittle superhard cutting elements for turning surfaces from dissimilar constructional materials, Izv. Vyssh. Uchebn. Zaved., Mashinostr., 2018, no. 2 (695), pp. 75–85.

Kudryashov, E.A. and Smirnov, I.M., Tool guarantee of intermittent cutting processes, Manuf. Technol., 2017, vol. 17, pp. 887–892.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Kudryashov, E.A., Smirnov, I.M. & Grishin, D.V. Selecting the Shape of the Insert in a Lathe Cutter. Russ. Engin. Res. 39, 1046–1049 (2019). https://doi.org/10.3103/S1068798X1912013X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X1912013X