Abstract

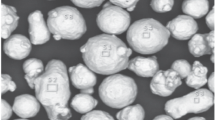

The laser heat treatment of sintered ZhGr ferrocarbon powder steel with different porosity is considered. The microstructure and microhardness of the steel are determined, and the defects arising in laser treatment are studied.

Similar content being viewed by others

REFERENCES

Antsiferov, V.N., Akimenko, V.B., and Grevnov, L.M., Poroshkovye legirovannye stali (Powder Alloyed Steels), Moscow: Metallurgiya, 1991.

Solov’eva, E.V. and Dovydenkov, V.A., Properties of iron-based materials obtained by infiltration and doped with Ni and Mo, Materialy vserossiiskoi molodezhnoi nauchno-tekhnicheskoi konferentsii “Sovremennoe materialovedenie: traditsii otechestvennykh nauchnykh shkol i innovatsionnyi podkhod” (Proc. All-Russ. Youth Sci.-Tech. Conf. “Modern Materials Science: Traditions of National Scientific Schools and Innovative Approach”), Moscow: Vseross. Inst. Aviats. Mater., 2017, pp. 198–202.

Dzyachkova, L.N., Kerzhentseva, L.F., and Vityaz’, P.A., Effect of steel skeleton composition on the triboengineering properties of steel-copper pseudoalloys produced by infiltration, J. Frict. Wear, 2010, vol. 31, no. 4, pp. 270–275.

Privalova, N.N. and Dovydenkov, V.A., Copper infiltrated material for the manufacture of plain bearings, Materialy mezhdunarodnoi mezhdistsiplinaronoi nauchnoi konferentsii “Sotsial’nye, estestvennye i tekhnicheskie sistemy v sovremennom mire: sostoyanie, protivorechiya, razvitie” (Proc. Int. Interdisciplinary Sci. Conf. “Social, Natural, and Technical Systems in the Modern World: Status, Contradictions, and Development”), Shalaev, V.P., Ed., Yoshkar-Ola: Povolzhsk. Gos. Tekh. Univ., 2015, pp. 274–276.

Gordeev, Yu.I., Abkaryan, A.K., Surovtsev, A.V., and Lepeshev, A.A., Investigation into the peculiarities of structure formation and properties of copper-based powder pseudoalloys modified by ZnO and TiN nanoparticle additives, Russ. J. Non-Ferrous Met., 2019, vol. 60, no. 1, pp. 68–75.

Privalova, N.N. and Alibekov, S.Ya., Antifriction material for plain bearings, Materialy mezhdunarodnoi mezhdistsiplinarnoi nauchnoi konferentsii “Rossiya v prostranstve global’nykh transformatsii: v fokuse nauk o cheloveke, obshchestve, prirode i tekhnike” (Proc. Int. Interdisciplinary Sci. Conf. “Russia in the Space of Global Transformations: Science about on a Man, Society, and Mechanics”), Shalaev, V.P., Ed., Yoshkar-Ola: Povolzhsk. Gos. Tekh. Univ., 2016, pp. 342–344.

Eremeeva, Zh.V., Nikitin, N.M., and Sharipzyanova, G.Kh., Heat treatment of powder steels with alloyed nanoscale additives, Materialy 77-i mezhdunarodnoi nauchno-tekhnicheskoi konferentsii “Avtomobile- i traktorostroenie v Rossii: prioritety razvitiya i podgotovka kadrov” (Proc. 77 Int. Sci.-Tech. Conf. “Automobile and Tractor Manufacturing in Russia: Priorities of Development and Human Resources”), Moscow: Mosk. Gos. Tekh. Univ., MAMI, 2012, pp. 61–70.

Grigor’yants, A.G. and Vasil’tsov, V.V., The spatial structure of the radiation of high-power waveguide and fiber lasers, Vestn. Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Ser. Mashinostr., 2012, no. 6, pp. 5–33.

Qui, F. and Kujanpää, V., Transformation hardening of medium-carbon steel with a fiber laser: the influence of laser power and laser power density, Mechanika, 2011, vol. 17, no. 3, pp. 318–323.

Goia, F. and de Lima, M., Surface hardening of an AISI D6 cold work steel using a fiber laser, J. ASTM Int., 2011, vol. 8, no. 2, pp. 315–318.

Safonov, A.N., Structure and microhardness of the surface layers of iron-carbon alloys after laser heat treatment, Met. Sci. Heat Treat., 1996, vol. 38, nos. 1–2, pp. 68–74.

Astapchik, S.A., Babushkin, V.B., and Ivashko, V.S., Structural and phase transformations in steels and alloys in laser heat treatment, Met. Sci. Heat Treat., 1991, vol. 33, no. 2, pp. 87–93.

Kraposhin, V.S., Effect of residual austenite on properties of steels and pig irons after surface melting, Met. Sci. Heat Treat., 1994, vol. 36, no. 2, pp. 63–68.

Kraposhin, V.S. and Kraposhina, I.F., The effect of laser irradiation parameters on the size of the irradiated zones for steel 45, Fiz. Khim. Obrab. Mater., 1989, no. 6, pp. 19–24.

Qui, F. and Kujanpää, V., Transformation hardening of medium carbon steel with a fiber laser, Mechanika, 2011, vol. 17, pp. 318–323.

Antsiferov, V.N., Shmakov, A.M., and Shtennikov, S.V., Structure formation mechanisms and properties of powdered carbon steels during laser thermal modification. I. Structure of modified steels, Sov. Powder Metall. Met. Ceram., 1992, vol. 31, no. 7, pp. 613–616.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Morozov, E.A., Oglezneva, S.A. & Usynin, E.V. Laser Heat Treatment of Ferrocarbon Powder Steel. Russ. Engin. Res. 39, 901–903 (2019). https://doi.org/10.3103/S1068798X19100162

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X19100162