Abstract

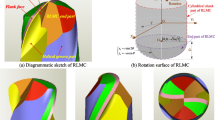

The article outlines a new approach to the design of specialized high-performance cutters for the machining of end channels.

Similar content being viewed by others

REFERENCES

Grechishnikov, V.A. and Pivkin, P.M., Cutting heads for trimming and cutting channels with a conical generatrix and end channels in parts of different configuration, Vestn. Mosk. Gos. Tekh. Univ., Stankin, 2014, no. 2 (29), pp. 50–56.

Bert, L., Optimal and collision free tool posture in five-axis machining through the tight integration of tool path generation and machine simulation, Computer-Aided Des., 2003, vol. 35, no. 5, pp. 421–432.

Worthington, B., The operation and performance of groove-type chip forming device, Int. J. Prod. Res., 1976, vol. 14, no. 5, pp. 529–558.

Khaet, L.G., Prochnost’ rezhushchego instrumenta (Durability of Cutting Tool), Moscow: Mashinostroenie, 1975.

Semenchenko, I.I., Matyushin, V.M., and Sakharov, G.N., Proektirovanie metallorezhushchego instrumenta (Engineering of Metal-Cutting Tools), Moscow: Mashgiz, 1963.

Rodin, P.R., Osnovy teorii proektirovaniya rezhushchego instrumenta (Basic Theory of Engineering of Cutting Tools), Moscow: Mashgiz, 1960.

Pivkin, P.M., The manufacturing of complete cutter for processing the complex-shape frontal grooves, Vestn. Mosk. Gos. Tekhnol. Univ., Stankin, 2016, no. 4 (39), pp. 40–46.

Grechishnikov, V.A. and Pivkin, P.M., RF Patent 120594, Byull. Izobret., 2012, no. 27.

Maslov, A.R., Instrumental’nye sistemy mashinsotroitel’nykh proizvodstv: uchebnik (Instrumental Systems of Machine Engineering Industries: Manual), Moscow: Mashinostroenie, 2006.

Druzhinskii, I.A., Slozhnye poverkhnosti: Matematicheskoe opisanie i tekhnologicheskoe obespechenie. Spravochnik (Complex Surfaces: Mathematical Description and Technological Supply. Handbook), Leningrad: Mashinostroenie, 1985.

Grubyi, S.V., Tatarova, L.A., and Vorob’eva, E.V., The use of carbide tools for processing of the frontal grooves on the parts for rocket and space devices, Inzh. Zh.: Nauka Innovatsii, 2014, no. 4, pp. 1–15.

Grechishnikov, V.A. and Pivkin, P.M., Machining of frontal grooves on car parts, Izv. Mosk. Gos. Tekh. Univ., MAMI, 2014, vol. 2, no. 1, pp. 76–79.

Grechishnikov, V.A., Maslov, A.R., and Pivkin, P.M., The system of turning cutters for machining the frontals on CNC machines, Vestn. Mosk. Gos. Tekh. Univ., Stankin, 2015, no. 8, pp. 16–19.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Grechishnikov, V.A., Pivkin, P.M., Isaev, A.V. et al. Cutters for Machining End Channels. Russ. Engin. Res. 38, 798–801 (2018). https://doi.org/10.3103/S1068798X18100106

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X18100106