Abstract

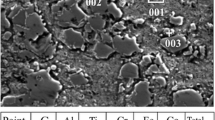

The resistance of single-carbide alloys with modified binder to high-temperature gas corrosion is investigated. Increase in the cobalt and molybdenum content in the hard alloys decreases their stability while adding iron and copper to the cobalt binder, along with a small quantity of titanium (up to 2%), improves the stability and performance of the alloys.

Similar content being viewed by others

References

Ryzhkin, A.A., Teplofizicheskie protsessy pri iznashivanii instrumental’nykh rezhushchikh materialov (Thermophysical Processes Occurring during Wear of Cutting Tools of Materials), Rostov-on-Don: Donsk. Gos. Tekh. Univ., 2005.

Ryzhkin, A.A., Bokov, A.I., Zotov, V.V., and Globa, D.P., External influences on wear of hard alloys, Vestn. Donsk. Gos. Tekh. Univ., 2010, no. 1, pp. 112–120.

Kulikov, M.Yu., Starikov, A.V., and Antipin, A.V., Effect of tribooxidation processes on wear and failure of metal-cutting tools, J. Frict. Wear, 2000, vol. 21, no. 6, pp. 62–66.

Kozlov, A.A. and Dement’ev, N.G., Stability of the heterogeneous oxide reactions on contact surfaces of rapid tools at metal machining, Vestn. Mashinostr., 2005, no. 4, pp. 57–61.

Migranov, M.Sh. and Shuster, L.Sh., Wear resistance of cutting tools with multilayered coatings, Trenie Iznos, 2005, no. 3, pp. 304–307.

Andreev, A.A. and Grigor’ev, S.N., Wear-resistant titanium-based vacuum-arc coatings in tool production, Russ. Eng. Res., 2006, vol. 26, no. 2, pp. 44–49.

Shuster, L.Sh., Migranov, M.Sh., Minigaleev, S.M., et al., Wear resistance of cutting tools with wear-resistant coatings, Trenie Smazka Mash. Mekh., 2007, no. 5, pp. 32–84.

Rudneva, V.V. and Galevskii, G.V., Thermooxidative stability of refractory carbide and boride nanpopowder, Steel Transl., 2007, vol. 37, no. 4, pp. 329–332.

Ryzhkin, A.A., Meskhi, B.Ch., Ilyasov, V.V., Bokov, A.I., Shchuchev, K.G., Aliev, M.M., Moiseenko, S.A., Vistoropskaya, F.A., and Moiseev, D.V., RF Patent 2531332, 2014.

Ryzhkin, A.A., Burlakova, V.E., Moiseev, D.V., Puchkin, V.N., and Fominoff, E.V., Determination of the efficiency of high-entropy cutting tool materials, J. Frict. Wear, 2016, vol. 37, no. 1, pp. 47–54.

GOST (State Standard) 6130–71: Metals and Method of Determining Their Heat Resistance, Moscow: Izd. Standartov, 1971.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.A. Ryzhkin, V.E. Burlakova, A.A. Novikova, 2018, published in Vestnik Mashinostroeniya, 2018, No. 3, pp. 50–54.

About this article

Cite this article

Ryzhkin, A.A., Burlakova, V.E. & Novikova, A.A. Wear and Performance of Hard Alloys. Russ. Engin. Res. 38, 438–441 (2018). https://doi.org/10.3103/S1068798X18060151

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X18060151