Abstract

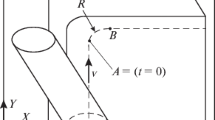

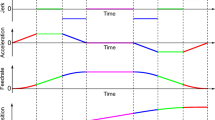

Possible manufacturing and assembly errors in a metal-cutting machine with parallel kinematic structure that affect its kinematic model are analyzed. On the basis of the manufacturing tolerances for the metal-cutting machine, the equations of the direct and inverse kinematic transformations are refined. An algorithm is derived for simulating the influence of geometric errors on the positioning precision of the actuator in the metal-cutting machine.

Similar content being viewed by others

References

Akmaev, O.K., Enikeev, B.A., and Nigmatullin, A.I., A machine tool with parallel two-level kinematics, Russ. Eng. Res., 2016, vol. 36, no. 2, pp. 129–133.

Akmaev, O.K., Enikeev, B.A., and Nigmatullin, A.I., A new machine tool with parallel kinematic structure, Russ. Eng. Res., 2016, vol. 36, no. 6, pp. 484–487.

Elatta, A.Y., Gen, L.P., Zhi, F.L., Daoyuan, Y., and Fei, A.L., Overview of robot calibration, Inf. Technol. J., 2004, vol. 3, no. 1, pp. 74–78.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © B.A. Enikeev, A.I. Nigmatullin, O.K. Akmaev, R.G. Kudoyarov, 2016, published in STIN, 2016, No. 10, pp. 4–9.

About this article

Cite this article

Enikeev, B.A., Nigmatullin, A.I., Akmaev, O.K. et al. Influence of manufacturing errors in a metal-cutting machine with parallel kinematic structure on its machining precision. Russ. Engin. Res. 37, 338–343 (2017). https://doi.org/10.3103/S1068798X17040086

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X17040086