Abstract

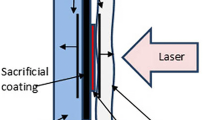

The principles of two-sided laser shock processing (LSP) are considered. The differences between two-sided and one-sided laser shock processing are noted. For the example of a thin VT-6 titanium-alloy plate, finite-element modeling is used to investigate the residual stress field when using two-sided LSP. The distribution of surface microhardness is analyzed.

Similar content being viewed by others

References

Birger, I.A., Ostatochenye napryazheniya (Residual Stresses), Moscow: Gos. Nauchno-Tekh. Izd. Mashinostr. Lit., 1963.

Peyre, P., Scherpereel, X., Berthe, L., et al., Current trends in laser shock processing, Surf. Eng., 1998, vol. 14, pp. 377–380.

Luo, K.Y., Liu, B., Wu, L.J., et al., Tensile properties, residual stress distribution and grain arrangement as a function of sheet thickness of Mg–Al–Mn alloy subjected to two-sided and simultaneous LSP impacts, Appl. Surf. Sci., 2016, vol. 369, pp. 366–376.

Zhang, X.Q., Li, H., Yu, X.L., et al., Investigation on effect of laser shock processing on fatigue crack initiation and its growth in aluminum alloy plate, Mater. Des., 2015, vol. 65, pp. 425–431.

Perminov, M.D., Solov’ev, V.O., Sakhvadze, G.J., et al., Otchet o Nauchno-issledovatel’skoi rabote (zaklyuchitel’nyi) no. 01201060703 “Vibratsionnye, vibroakusticheskie protsessy i tekhnologii, vklyuchaya protsessy upravleniya i informatizatsii v sistemakh “chelovekmashina- sreda”” (Final Report on Scientific Research Work No. 01201060703 “Vibration, Vibroacoustic Processes and Technologies Including control Processes and Informatization in the “Man-Machine-Environment” Systems”), 2012, parts 1–3.

Irizalp, S.G., Saklakoglu, N., Akman, E., et al., Pulsed Nd:YAG laser shock processing effects on mechanical properties, Opt. Laser Technol., 2014, vol. 56, pp. 273–277.

Ocana, J.L., Morales, M., Porro, J.A., et al., Induction of thermo-mechanical residual stresses in metallic materials by laser shock processing, in Encyclopedia of Thermal Stresses, New York: Springer-Verlag, 2014, pp. 2427–2444.

Ocana, J.L., Porro, J.A., Morales, M., et al., Laser shock processing: an emerging technique for the enhancement of surface properties and fatigue life of high-strength metals, Int. J. Microstruct. Mater. Prop., 2013, vol. 8, nos. 1–2, pp. 38–52.

Zel’dovich, Yu.B. and Raizer, Yu.P., Fizika udarnykh voln i vysokotemperaturnykh gidrodinamicheskikh yavlenii (Physics of the Shock Waves and High Temperature Hydrodynamic Phenomena), Moscow: Fizmatlit, 2008.

Hu, Y. and Yao, Z., Numerical simulation and experimentation of overlapping laser shock processing with symmetry cell, Int. J. Mach. Tools Manuf., 2008, vol. 48, pp. 152–162.

Grigor’yants, A.G., Shiganov, I.N., and Misyurov, A.I., Tekhnologicheskie protsessy lazernoi obrabotki (Technological Processes of Laser Treatment), Moscow: Mosk. Gos. Tekh. Univ. im. N.E. Baumana, 2008.

Johnson, G.R. and Cook, W.H., A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures, Proc. 7-th Int. Sym. on Ballistics, Hague, 1983, pp. 541–547.

Sakhvadze, G.J. Laser shock processing of materials to produce nanostructures, Probl. Mech., 2014, no. 2 (55), special issue, pp. 68–73.

Stolyarov, V.V., Sakhvadze, G.J., and Baranov, Yu.V., Pulse processing technologies for obtaining of nanomaterials, Konstr. Kompoz. Mater., 2007, no. 3, pp. 13–20.

Sakhvadze, G.J. and Gavrilina, L.V., Laser shock wave treatment of materials at the single and multiple pulse exposures, Probl. Mashinostr. Nadezhn. Mash., 2015, no. 6, pp. 75–80.

Sakhvadze, G.J., Gavrilina, L.V., and Kikvidze, O.G., Influence of overlapping laser spots on the residual stress in laser shock wave treatment of materials, Probl. Mashinostr. Nadezhn. Mash., 2016, no. 3, pp. 77–84.

Carlsson, S. and Larsson, P.L., On the determination of residual stress and strain fields by sharp indentation testing. Part 1: theoretical and numerical analysis, Acta Mater., 2001, vol. 49, pp. 2179–2191.

Sakhvadze, G.J., Bulekbaeva, G.Zh., and Kikvidze, O.G., Quality analysis of surface layers hardened by laser shock wave technology at the different degrees of overlapping laser spots, Probl. Mashinostr. Avtom., 2016, no. 2, pp. 132–141.

Moskvitin, G.V., Birger, E.M., and Polyakov, A.N., Laser hardening to reduce metal fatigue, Russ. Eng. Res., 2012, vol. 32, no. 7, pp. 546–549.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.Zh. Sakhvadze, M.S. Pugachev, O.G. Kikvidze, 2016, published in Vestnik Mashinostroeniya, 2016, No. 10, pp. 71–76.

About this article

Cite this article

Sakhvadze, G.Z., Pugachev, M.S. & Kikvidze, O.G. Two-sided laser shock processing. Russ. Engin. Res. 37, 40–45 (2017). https://doi.org/10.3103/S1068798X17010191

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X17010191