Abstract

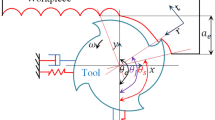

The use of synergetic concepts in studying the steady shaping trajectories of the tool relative to the workpiece in end milling is discussed, with allowance for elastic displacements and their stability. A two-level hierarchy of dynamic equations is employed. At the first level, steady trajectories are considered. At the second, their stability is analyzed on the basis of variational equations for these trajectories. The case in which the pulsed reaction of the system is an order of magnitude less than one period of the displacement cycle is considered.

Similar content being viewed by others

References

Prigogine, I. and Stengers, I., Order Out of Chaos, Ann Arbor, MI: Univ. of Michigan Press, 1984.

Prigogine, I. and Stengers, I., Order Out of Chaos: Man’s New Dialogue with Nature, New York: Bantam Books, 1984.

Haken, H., Advanced Synergetics: Instability Hierarchies of Self-Organizing Systems and Devices, New York: Springer-Verlag, 1993.

Haken, H., Erfolgsgeheimnisse der Natur, Synergetik: Die Lehre vom Zusammenwirken, Stuttgart: Deutsche Verlags-Anstalt, 1981.

Kolesnikov, A.A., Sinergeticheskaya teoriya upravleniya (Synergetic Theory of Control), Moscow: Energoatomizdat, 1994.

Sinergetika i problemy teorii upravleniya (Synergetic and Problems of Control Theory), Kolesnikov, A.A., Ed., Moscow: Fizmatlit, 2004.

Zakovorotny, V.L. and Flek, M.B., Dinamika protsessa rezaniya. Sinergeticheskii podkhod (Dynamics of Cutting Process: Synergetic Approach), Rostov-on-Don: Terra, 2006.

Zakovorotny, V.L., Lukyanov, A.D., Nguen, D.A., and Fam, D.T., Sinergeticheskii sistemnyi sintez upravlyaemoi dinamiki metallorezhushchikh stankov s uchetom evolyutsii svyazei (Synergetic System Synthesis of Controlled Dynamics of Metal Cutting Machines, Taking into Account the Evolution of Relations), Rostov-on-Don: Donsk. Gos. Tekh. Univ., 2008.

Zakovorotny, V.L. and Lukyanov, A.D., The problems of control of the evolution of the dynamic system interacting with the medium, Int. J. Mech. Eng. Autom., 2014, vol. 1, no. 5, pp. 271–285.

Tlustý, J., Samobuzené Kmity v Obrábecích Strojích, Praha: Cesk. Akad. Ved., 1954.

Tlustý, J., Polacek, A., Danek, C., and Spacek, J., Selbsterregte Schwingungen an Werkzeugmaschinen, Berlin: VEB Verlag Technik, 1962.

Tobias, S.A., Machine Tool Vibrations, London: Blackie, 1965.

Kudinov, V.A., Dinamika stankov (Dynamics of Machines), Moscow: Mashinostroenie, 1967.

El’yasberg, M.E., Avtokolebaniya metallorezhushchikh stankov: teoriya i praktika (Auto-Oscillations of Machine Tools: Theory and Practice), St. Petersburg: Osoboe Konstr. Byuro Stankostr., 1993.

Veits, V.L. and Vastil’kov, D.V., Dynamics, modeling, and quality maintenance at the machine treatment of small hard billets, Stanki Instrum., 1999, no. 6, pp. 9–13.

Zakovorotny, V.L., Fam D.T., and Nguen S.T., Mathematical modeling and parametric identification of dynamic properties of the tool and billet subsystem, Izv. Vyssh. Uchebn. Zaved., Sev.-Kavk. Reg., Tekh. Nauki, 2011, no. 2, pp. 38–46.

Sokolovskii, A.P., Vibratsii pri rabote na metallorezhushchikh stankakh. Issledovanie kolebanii pri rezanii metallov (Vibration at Working on Metal Cutting Machines: Analysis of Vibrations at Metal Cutting), Moscow: Mashgiz, 1958, pp. 15–18.

Murashkin, L.S. and Murashkin, S.L., Prikladnaya nelineinaya mekhanika stankov (Applied Nonlinear Mechanics of Machines), Leningrad: Mashinostroenie, 1977.

Zakovorotny, V.L., Bifurcations in the dynamic system of the mechanic processing in metal-cutting tools, J. Trans. Appl. Theor. Mech., 2015, vol. 10, pp. 102–116.

Zakovorotny, V.L., Fam, D.T., and Bykador, V.S., Self-organization and bifurcation of dynamic system for metal cutting, Izv. Vyssh. Uchebn. Zaved., Prikl. Nelineinaya Din., 2014, vol. 22, no. 3, pp. 26–40.

Zakovorotny, V.L., Fam, D.T., and Bykador, V.S., Influence of flexural deformations of tool on self-organization and bifurcation of dynamic system of metal cutting, Izv. Vyssh. Uchebn. Zaved., Prikl. Nelineinaya Din., 2014, vol. 22, no. 3, pp. 40–53.

Stepan, G., Delay-differential equation models for machine tool chatter, in Nonlinear Dynamics of Material Processing and Manufacturing, Moon, F.C., Ed., New York: Wiley, 1998, pp. 165–192.

Stepan, G., Insperge, T., and Szalai, R., Delay,parametric excitation,and the nonlinear dynamics of cutting processes, Int. J. Bifurcation Chaos Appl. Sci. Eng., 2005, vol. 15, no. 9, pp. 2783–2798.

Tobias, S.A. and Fishwick, W., Theory of regenerative machine tool chatter, Engineer, 1958, vol. 205, pp. 199–203.

Merritt, H.E., Theory of self-excited machine tool chatter, ASME J. Eng. Ind., 1965, vol. 205, no. 11, pp. 447–454.

Sridhar, R., Hohn, R.E., and Long, G.W., A stability algorithm for the general milling process: Contribution to machine tool chatter research-7, ASME J. Eng. Ind., 1968, vol. 90, no. 2, pp. 330–334.

Altintas, Y. and Budak, E., Analytical prediction of stability lobes in milling, Ann. CIRP, 1995, vol. 44, no. 1, pp. 357–362.

Tlusty, J. and Ismail, F., Special aspects of chatter in milling, ASME J. Vibrat., Stress, Reliab. Des., 1983, vol. 105, no. 1, pp. 24–32.

Minis, I. and Yanushevsky, T., A new theoretical approach for the prediction of machine tool chatter in milling, Trans. ASME J. Eng. Ind., 1993, vol. 115, no. 2, pp. 1–8.

Insperger, T. and Stepan, G., Stability of the milling process, Period. Polytech.-Mech. Eng., 2000, vol. 44, no. 1, pp. 47–57.

Budak, E. and Altintas, Y., Analytical prediction of chatter stability in milling. Part I: General formulation, ASME J. Dyn. Syst., Meas., Control, 1998, vol. 120, no. 6 (1), pp. 22–30.

Budak, E. and Altintas, Y., Analytical prediction of chatter stability conditions for multi-degree of systems in milling. Part II: Applications, ASME J. Dyn. Syst., Meas., Control, 1998, vol. 120, no. 6 (1), pp. 31–36.

Merdol, D. and Altintas, Y., Multi-frequency solution of chatter stability for low immersion milling, ASME J. Manuf. Sci. Eng., 2004, vol. 126, no. 3, pp. 459–466.

Insperger, T., Mann, B., Stepan, G., and Bayly, P.V., Stability of up-milling and down-milling. Part 1: Alternative analytical methods, Int. J. Mach. Tools Manuf., 2003, vol. 43, no. 1, pp. 25–34.

Kline, W.A., Devor, R.E., and Shareef, I.A., The prediction of surface accuracy in end milling, ASME J. Eng. Ind., 1982, vol. 104, no. 5, pp. 272–278.

Elbestawi, M.A. and Sagherian, R., Dynamic modeling for the prediction of surface errors in milling of thin-walled sections, Theor. Comp. Fluid Dyn., 1991, vol. 25, no. 2, pp. 215–228.

Campomanes, M.L. and Altintas, Y., An improved time domain simulation for dynamic milling at small radial immersions, Trans. ASME. J. Manuf. Sci. Eng., 2003, vol. 125, no. 3, pp. 416–425.

Paris, H., Peigne, G., and Mayer, R., Surface shape prediction in high-speed milling, Int. J. Mach. Tools Manuf., 2004, vol. 44, no. 15, pp. 1567–1576.

Altintas, Y. and Lee, P., A general mechanics and dynamics model for helical end mills, Ann. CIRP, 1996, vol. 45, no. 1, pp. 59–64.

Ozturk, E. and Budak, E., Modeling of 5-axis milling processes, Mach. Sci. Technol., 2007, vol. 11, no. 3, pp. 287–311.

Budak, E., Ozturk, E., and Tunc, L.T., Modeling and simulation of 5-axis milling processes, Ann. CIRP, 2009, vol. 58, no. 1, pp. 347–350.

Bravo, U., Altuzarra, O., Lopez de Lacalle, L.N., et al., Stability limits of milling considering the flexibility of the workpiece and the machine, Int. J. Mach. Tools Manuf., 2005, vol. 45, pp. 1669–1680.

Weinert, K., Kersting, P., Surmann, T., and Biermann, D., Modeling regenerative workpiece vibrations in five-axis milling, Prod. Eng. Res. Dev., 2008, no. 2, pp. 255–260.

Biermann, D., Kersting, P., and Surmann, T., A general approach to simulating workpiece vibrations during five-axis milling of turbine blades, Ann. CIRP, 2010, vol. 59, no. 1, pp. 125–128.

Voronov, S.A., Kiselev, I.A., and Arshinov, S.V., Implementation of numerical modeling of dynamics of multidimensional milling of complex profile parts during design of technological process, Vestn. Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Ser.: Mashinostr., 2012, no. 6, pp. 50–69.

Voronov, S.A., Nepochatov, A.V., and Kiselev, I.A., Assessment criteria of stability of milling of non-rigid parts, Izv. Vyssh. Uchebn. Zaved., Mashinostr., 2011, no. 1 (610), pp. 50–62.

Voronov, S. and Kiselev, I., Dynamics of flexible detail milling, Proc. Inst. Mech. Eng., K, 2011, vol. 225, no. 3, pp. 1177–1186.

Zakovorotny, V.L., Panov, E.Yu., and Potapenko, P.N., Properties of shaping motions during drilling of smalldiameter deep holes, Vestn. Donsk. Gos. Tekh. Univ., 2001, vol. 1, no. 2, pp. 81–93.

Pontryagin, L.S., Izbrannye trudy (Selected Research Works), Moscow: Nauka, 1988, vol. 2.

Tikhonov, A.N., Vasil’ev, A.B., and Volosov, V.M., Differential equations containing a small parameter, Tr. mezhd. simp. po nelineinym kolebaniyam (Proc. Int. Symp. on Nonlinear Oscillations), Kiev: Akad. Nauk UkrSSR, 1963, pp. 56–61.

Zakovorotnyj, V.L., Fam D.T., and Nguen S.T., Simulation of deformation shifts of the turning tool regards to the billet, Vestn. Donsk. Gos. Tekh. Univ., 2010, vol. 7 (50), pp. 1005–1015.

D’Angelo, R., Linear Time-Varying Systems: Analysis and Synthesis, Boston: Allyn and Bacon, 1970.

Lyapunov, A.M., Obshchaya zadacha ob ustoichivosti dvizheniya (General Problem of Motion Stability), Moscow: Gostekhizdat, 1950.

Berezkin, E.N., Lektsii po teoreticheskoi mekhanike (Lecturers on Theoretical Mechanics), Moscow: Mosk. Gos. Univ., 1968.

Zakovorotny, V.L. and Ladnik, I.V., Compilation of information model of the dynamic system of the metalcutting machine for the diagnosis of treatment process, Probl. Mashinostr. Nadezhnosti Mash., 1991, no. 4, pp. 75–81.

Zakovorotny, V.L., Bordachev, E.V., and Alekseichik, M.I., Dynamic monitoring of the status of the cutting process, Stanki Instrum., 1998, no. 12, pp. 6–12.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.L. Zakovorotny, A.A. Gubanova, A.D. Lukyanov, 2016, published in STIN, 2016, No. 4, pp. 32–40.

About this article

Cite this article

Zakovorotny, V.L., Gubanova, A.A. & Lukyanov, A.D. Stability of shaping trajectories in milling: Synergetic concepts. Russ. Engin. Res. 36, 956–964 (2016). https://doi.org/10.3103/S1068798X16110216

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X16110216