Abstract

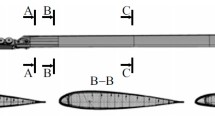

Theoretical analysis of composite blades for gas-turbine engines is based on the theory of effective moduli and the Lagrange equations. The blades are regarded as twisted rods; the flexure-approximation coefficients are adopted as generalized coordinates.

Similar content being viewed by others

References

Pavlov, V.P., Nusratullin, E.M., and Filippov, A.A., Durability of the vane of the compressor of the aviation engine at replacement of the titanic alloy by the composite material, Vestn. Ufimsk. Gos. Aviats. Tekh. Univ., 2011, vol. 15, no. 4, pp. 98–106.

Eliseev, V.V., Mekhanika uprugikh tel (Mechanics of Elastic Bodies), St. Petersburg: S.-Peterb. Politekh. Univ., 2003.

Anoshkin, A.N., Zuiko, V.Yu., Shipunov, G.S., and Tretyakov, A.A., Technologies andproblems of composite materials mechanics for production of outlet guide vane foraircraft jet engine, PNRPU Mech. Bull., 2014, no. 4, pp. 5–44.

Pervushin, Yu.S. and Solov’ev, P.V., A definition of the elastic mechanical and heat stresses multilayer system analytical model in solving the tasks of the oxidation resistant aluminide coatings create, Vestn. Ufimsk. Gos. Aviats. Tekh. Univ., 2013, vol. 17, no. 3, pp. 253–259.

Christensen, R.M., Mechanics of Composite Materials, New York: Wiley, 1979.

Samsonov, G.V., Tugoplavkie soedineniya: spravochnik (Refractory Materials: Handbook), Moscow: Metallurgiya, 1976.

Budinovskii, S.A., A definition of the elastic mechanical and heat stresses multilayer system analytical model in solving the tasks of the oxidation resistant aluminide coatings create, Strengthening Technol. Coat., 2013, no. 3, pp. 3–11.

Kolesnikov, V.I., Bardushkin, V.V., Sychev, A.P., and Yakovlev, V.B., Effect of microstructure on the local values of stress and deformations in fiber composite, Vestn. Mashinostr., 2005, no. 8, pp. 35–38.

Eliseev, V.V., Moskalets, A.A., and Oborin, E.A., Onedimensional models in turbine blades dynamics, in Advances in Mechanical Engineering, Evgrafov, A., Ed., New York: Springer-Verlag, 2016. pp. 93–104.

Kir’yanov, D.V., Mathcad 14, St. Petersburg: BKhVPeterburga, 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Eliseev, V.A. Piskunov, 2016, published in Vestnik Mashinostroeniya, 2016, No. 7, pp. 42–44.

About this article

Cite this article

Eliseev, V.V., Piskunov, V.A. Composite gas-turbine blades. Russ. Engin. Res. 36, 819–822 (2016). https://doi.org/10.3103/S1068798X16100087

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X16100087