Abstract

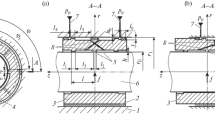

Ultrasonic and acoustic axial spindle oscillations improve the productivity and product quality in machining, reduce the cutting forces, and increase the tool life in the grinding, milling, and boring of structural components, including those made from materials that are hard to machine. Industrial prototypes of motorized spindles with axial spindle oscillations have been developed by specialists at Siberian Federal University and AO NPP Radiosvyaz and patented in Russia. These spindle units include contactless hydrostatic bearings, a resonant-frequency generator (a piezo generator for ultrasonic spindles and a hydromechanical generator for acoustic spindles), and a local concentrator for the spindle’s longitudinal intrinsic waves.

Similar content being viewed by others

References

Kang, J.H., A study on an ultrasonic vibration assisted grinding for ceramics, Trans. Korean Soc. Automot. Eng., 1996, vol. 4, no. 5, pp. 37–48.

Onikura, H., Ohnishi, O., Take, Y., and Kobayashi, A., Fabrication of micro carbide tools by ultrasonic vibration grinding, CIRP Ann., 2000, vol. 49, pp. 257–260.

Wu, Y., Nomura, M., Kato, M., and Tachibana, T., Study of internal ultrasonic vibration assisted grinding of small holes—construction of ultrasonic vibration spindle and its fundamental performances, J. Jpn. Soc. Abrasive Technol., 2003, vol. 47, no. 12, pp. 550–555.

Choi, Y.J., Park, K., Hong, H., Kim, K., Lee, S.W., and Choi, H.Z., Effect of ultrasonic vibration in grinding; horn design and experiment, Int. J. Precis. Eng. Manuf., 2013, vol. 14, no. 11, pp. 1873–1879.

Nomura, M., Wu, Y., Kato, M., Tachibana, T., and Kuriyagawa, T., Study of internal ultrasonic vibration assisted grinding of small holes—mechanism of grinding force reduction due to ultrasonic vibration, J. Jpn. Soc. Abrasive Technol., 2005, vol. 49, no. 12, pp. 691–696.

Yang, X.H., Han, J.C., Zhang, Y.M., Zuo, H.B., and Zhang, X.J., Research on ultrasonic vibration grinding of the hard and brittle materials, Chin. J. Aeronaut., 2006, vol. 19, pp. 9–13.

Shimada, K., Zhou, T., Yan, J., and Kuriyagawa, T., Statistical approach for calculating ground surface roughness of ultrasonic assisted grinding, J. Jpn. Soc. Abrasive Technol., 2012, vol. 56, no. 11, pp. 752–757.

Shimada, K., Tateishi, T., Yoshihara, N., Yan, J., and Kuriyagawa, T., Ultrasonic-assisted micro-grinding with electroplated diamond wheels, J. Jpn. Soc. Abrasive Technol., 2009, vol. 53, no. 1, pp. 45–48.

Park, K.H. and Kwon, P.Y., Flank wear of multi-layer coated tool and wear prediction using abrasive wear model, Proc. ASME Int. Manufacturing Science and Engineering Conf., West Lafayette, IN: Am. Soc. Mech. Eng., 2009, vol. 1, pp. 331–340.

Cong, W.L., Feng, Q., Pei, Z.J., Denies, T.W., and Treadwell, C., Experimental study on cutting temperature in rotary ultrasonic machining, Proc. Conf. of North American Manufacturing Research Institution/SME 2011, Corvallis, OR, 2011, vol. 39.

Tawakoli, T. and Azarhoushang, B., Effects of ultrasonic assisted grinding on CBN grinding wheels performance, Proc. ASME Int. Manufacturing Science and Engineering Conf., October 4–7, 2009, West Lafayette, IN, 2009.

Wu, J., Cong, W., Williams, R., and Pei, Z.J., Stochastic modeling and analysis of rotary ultrasonic machining, Proc. ASME Int. Manufacturing Science and Engineering Conf., October 4–7, 2009, West Lafayette, IN

Kul’kov, A.V., Abrasive superfinishing using ultrasound, Izv. Volgograd. Gos. Tekh. Univ., 2010, no. 6, pp. 20–26.

Kobayashi, S., Shimada, K., Murakoshi, C., Koike, K., Takahashi, M., and Tachibana, T., Development of an ultrasonically-assisted electrolytic grinding system, Int. J. Autom. Technol., 2013, vol. 7, no. 6, pp. 654–662.

Karev, E.A. and Tulisov, I.N., Efficiency improvement of the round external grinding by axial oscillation of billets, Vestn. Ul’yanovsk. Gos. Tekh. Univ., 2004, no. 4, pp. 32–34.

Smol’nikov, N.Ya., Agapov, S.I., Fedyanov, N.A., and Korpelyanskii, O.F., Analysis of possible introduction of ultrasonic oscillations into the cutting zone, Izv. Volgograd. Gos. Tekh. Univ., 2009, no. 5, pp. 47–50.

Lee, B.G., Kim, K.L., and Kim, K.E., Design of ultrasonic vibration tool horn for micromachining using FEM, Trans. Korean Soc. Mach. Tool Eng., 2008, vol. 17, no. 6, pp. 63–70.

Choi, Y.J., Park, K., Hong, H., Kim, K., Lee, S.W., and Choi, H.Z., Effect of ultrasonic vibration in grinding; horn design and experiment, Int. J. Precis. Eng. Manuf., 2013, vol. 14, no. 11, pp. 1873–1879.

Wu, Y., Yokoyama, S., Sato, T., Lin, W., and Tachibana, T., Development of a new rotary ultrasonic spindle for precision ultrasonically assisted grinding, Int. J. Mach. Tools Manuf., 2009, vol. 49, pp. 933–938.

Wu, Y., Tamano, M., Kato, M., and Tachibana, T., Inducing a machine spindle to ultrasonically vibrate by fluctuating electromagnetic force, Int. J. Appl. Electromagn. Mech., 2005, vol. 25, pp. 621–626.

Kobayashi, S., Shimada, K., Murakoshi, C., Koike, K., Takahashi, M., Tachibana, T., and Kuriyagawa, T., Development of an ultrasonically-assisted electrolytic grinding system, Int. J. Autom. Technol., 2013, vol. 7, no. 6, pp. 654–662.

Zeng, W.M., Li, Z.C., Churi, N.J., Pei, Z.J., and Treadwell, C., Experimental investigation into rotary ultrasonic machining of alumina, ASME 2004 Int. Mechanical Engineering Congress and Exposition, Anaheim, CA, November 13–19, 2004, New York: Am. Soc. Mech. Eng., 2004, no. IMECE2004-61700, pp. 207–212.

Shatokhin, S.N., Kurzakov, A.S., and Golovin, A.O., RF Patent 2556157, 2004.

Shatokhin, S.N., Pikalov, Ya.Yu., and Demin, V.G., Adaptive contactless sliding bearings with floating regulators of lubrication supply (hydrostatic, aerostatic) for spindle assemblies and guided metal cutting machines, Tekhnol. Mashinostr., 2006, no. 9, pp. 29–33.

Elka Precision Company, Hydrostatic precision grinding spindles and milling spindles. http://www.elkaprecision. com.

Kashchenevsky, L., US Patent 8646979, 2014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.N. Shatokhin, A.O. Golovin, 2016, published in STIN, 2016, No. 1, pp. 29–33.

About this article

Cite this article

Shatokhin, S.N., Golovin, A.O. Ultrasonic motorized spindle with hydrostatic bearings. Russ. Engin. Res. 36, 692–695 (2016). https://doi.org/10.3103/S1068798X16080190

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X16080190