Abstract

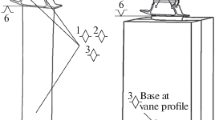

An effective method of machining the geometrically complex surfaces of compressor blades in gas-turbine engines is considered (creep-feed grinding). This method is widely used in the machining of hard materials such as high-temperature nickel alloys and cobalt alloys employed in the manufacture of gas-turbine components.

Similar content being viewed by others

References

Poletaev, V.A., Tekhnologiya avtomatizirovannogo proizvodstva lopatok gazoturbinnykh dvigatelei (Technology of Automated Production of the Blades of Gas Turbine Engines), Moscow: Mashinostroenie, 2006.

Poletaev, V.A., Starkov, V.K., Krylov, V.N., et al., Tekhnologiya avtomatizirovannoi kompleksnoi obrabotki lopatok turbin metodami vysokoproizvoditel’nogo shlifovaniya, mnogotselevye shlifoval’nye stanki i vysokostrukturnyi abrazivnyi instrument dlya ee realizatsii (Technology of Automated Complex Processing of the Turbine Blades by High Efficient Grinding, Multipurpose Grinding Machines, and Highly Structural Abrasive Tools), Moscow: Mashinostroenie, 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.A. Poletaev, E.V. Tsvetkov, 2015, published in STIN, 2015, No. 6, pp. 34–36.

About this article

Cite this article

Poletaev, V.A., Tsvetkov, E.V. Automated manufacture of compressor-blade tailpieces. Russ. Engin. Res. 36, 74–76 (2016). https://doi.org/10.3103/S1068798X16010172

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X16010172